On December 18, the official website of the Guangzhou Municipal Administration and Comprehensive Law Enforcement Bureau published the "Status Quo and Outlook of waste plastic recycling and utilization in domestic waste" article, pointing out that the current waste plastic treatment technology and degradable technology are immature, degradable plastics are mainly PLA and PBAT, and degradable plastics are still not widely promoted, mainly because of their performance and cost.

The article suggested that in addition to the introduction of policies to clearly support the promotion and application of degradable plastics, the recycling and disposal of such materials and products should be clearly stipulated at the legal level to improve the standardization of the degradable plastics industry.

The government has increased funds to support the research and development and innovation of degradable plastics, and it is still necessary to reduce the production cost of lactic acid in the future, expand the production capacity and reduce the cost of succinic acid and 1, 4-butanediol. Foster a good industrial environment and encourage advanced enterprises to participate in research and development. Guide enterprises to actively carry out deeper industry-university-research cooperation with universities and research institutes, and develop degradable plastics with excellent performance and economic benefits to replace non-degradable plastics.

The original text reads as follows:

Current situation and prospect of recycling and utilization of waste plastics in domestic waste

Source: Guangzhou Municipal Administration and Comprehensive Law Enforcement Bureau

First, the recycling and recycling status of waste plastics in China

Since the reform and opening up, China's social economy has developed rapidly, people's living standards have been rapidly improved, and the fast-paced life has changed our consumption mode and spawned a fast market. Plastic products are widely used in social production and daily life for their advantages of lightweight, durable and low price. Plastics bring fast and convenient to people at the same time, with the continuous expansion of the industrial scale of the plastic products industry, products and output increase year by year, the production of waste plastics also increases, and the production of waste plastics in China is large. According to statistics, the amount of waste plastics produced in 2019 was 63 million tons, and the recovery rate of waste plastics was only 30%, and recycling accounted for a relatively small proportion. According to Yang Na and other research shows that in Beijing, Shanghai, Guangzhou, Shenzhen and other cities, waste plastics accounted for about 13.1%-21.8% of the domestic waste, accounting for only kitchen waste.

2. Existing problems

1. The legal system is not perfect

Although China has laws and policies and regulations related to plastics, the top-level design is imperfect, the management policies of the whole industrial chain are imperfect, and laws and regulations that coordinate environmental protection and economic development such as green procurement, packaging, and household appliance recycling have not been introduced, and a systematic legal system has not been formed.

(2) The extended producer responsibility system is not perfect

Although The General Office of the State Council issued the "Implementation Plan for the Extended Producer Responsibility System" in 2017, clearly implementing the extended producer responsibility system, the extended producer responsibility system is not running smoothly, and the obligations and legal responsibilities of producers, sellers and consumers of various plastic products in domestic waste are not segmsegmed and clarified at the policy and regulatory level.

(3) The subsidy policy is difficult to implement

High-value waste plastics can be recycled through the recycling system of renewable resources, however, most low-value waste plastics can not be effectively classified and properly processed due to various types, different forms, difficulties in distinguishing, pollution and other reasons, and the impact on the environment and resources is becoming increasingly prominent. At present, only some cities such as Guangzhou and Shanghai have introduced a catalogue of low-value recyclables subsidy, but after research and understanding, because most of the enterprises dealing with low-value waste plastics are difficult to get subsidies, most of them operate at a loss, such as Guangzhou must have waste plastics from domestic waste accounts and other evidence.

(4) The definition of recyclability is not clear

At present, China has not clearly defined the definition of "recyclability", and the domestic definition and evaluation indicators of "recyclability of plastics and their products" are not clear, and it does not tell producers, sellers and consumers from the perspective of plastic product recycling what kind of products are easy to recycle, can be recycled, and can produce high-quality recycled plastic products. What kind of product design is no follow-up recycling channels, no recycling ways, can only be incinerated. At present, China's standards or guidelines for the recyclability design of plastic products are basically blank, which is not conducive to residents.

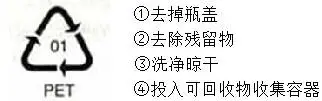

(5) The recycling mark of recyclables is not detailed

At present, although China has "packaging recycling mark" (GB 18455-2016) and "plastic packaging products recycling mark" (GBT16288-1996), most plastic products have signs to indicate what material is, but they do not specify the steps of cleaning recyclables, resulting in most residents do not understand how to deal with waste plastic products. Lack of guidance.

(6) The traceability and certification system has not been established

In the entire circulation process of "production - sales - use - recycling - recycling", plastic products have problems such as incomplete information, difficulty in tracing the source and lack of certification, and lack of content and safety certification of recycled plastics. The lack of traceability and certification systems will lead to the practical implementation of the extended producer responsibility system, which is not conducive to the implementation of the enterprise recycling, processing, recycling treatment expenditure subsidy system and the purchase of recycled plastic products with recycling labels.

(7) Statistical data are not supported

Waste plastics can be divided into industrial sources and domestic sources according to the source, industrial sources and domestic sources of waste plastics statistical departments are different, statistical caliber is different, statistical methods are different. The statistical departments of waste plastics for living sources mainly include housing and construction departments (urban management departments) and supply and marketing cooperatives. According to the research results, supply and marketing cooperatives can only count the amount of waste plastics collected by their affiliated recycling stations, while private recycling stations are more difficult to statistical because of the large number and difficult management. Most urban housing and construction departments (urban management departments) do not grasp the components of waste plastics in domestic waste, and can not count the content of waste plastics in domestic waste. At present, China has not yet formed a full-chain statistical system, waste plastic statistics are not supported, various departments have not formed a joint force, and it is impossible to settle the environmental account.

(8) Waste plastic treatment technology and degradable technology is not mature

The existing waste plastic treatment technology can not independently achieve the purpose of recycling, reducing and harmless waste plastic treatment. Waste plastic landfill can not realize the utilization of resources, but also occupy land resources. The incineration process is simple, does not require pretreatment, and the reduction effect is good. However, there is no specific plastic incinerator in China at present, and the dioxin generated by waste plastic incineration pollutes the environment and affects human health. Simple recycling technology does not destroy the chemical structure of plastics, less secondary pollution, but requires a single composition of plastics, China's garbage classification accuracy is generally poor, more impurities, poor cleanliness, unwashed waste plastics in domestic waste can generally only sell more than 100 yuan/ton, washed more than 300 yuan/ton, low price. The grade of the product made is low, and it can only be sold to 1800-2000 yuan/ton after granulation. Modified recycling can produce higher-grade products, but the process is more complex, requires specific machinery and equipment, and there are secondary pollution problems in the production process. Energy recycling, also known as thermal energy recycling, calorific value for recycling has a high value, but the technology requires a special incinerator, a large investment, if the waste plastic mixed with PVC, will also produce dioxins, pollution of the environment, affecting human health. Thermal cracking of waste plastics has the advantages of high product value and unlimited reuse times of waste plastics, but this technology requires a high degree of separation and sorting of waste and plastics, and needs to increase the pretreatment process. The process flow of this technology is more complex, and the technical operation requirements are strict, and it is difficult to carry out large-scale production. There are other new technologies and processes for waste plastic treatment, such as waste plastic gasification technology and green building materials, etc., the technology is still immature, the construction and operation costs are high, and it is difficult to widely promote.

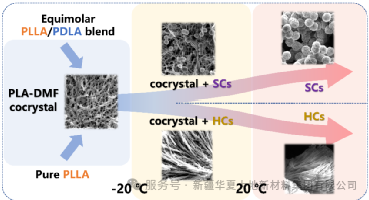

Biodegradable plastics are mainly PLA and PBAT, and biodegradable plastics are still not widely promoted, mainly because of their performance and cost. PLA has poor film forming performance and hydrolysis resistance. PBAT transparency and hardness are low, PBAT price is higher than PLA, and PLA plastic bag wholesale price is 0.3 yuan /, compared with 0.04-0.06 yuan/non-degradable plastic bags, the price is high, completely without price advantage.

Iii. Suggestions

1. Improving laws and regulations

Accelerate the improvement of the relevant legal system for plastic waste reduction and recycling, form a series of sound waste plastic legal management systems such as green procurement, container packaging, home appliance recycling, electronic and electrical recycling, and formulate relevant economic policy support, especially to improve the gaps in the recycling laws and regulations of emerging plastic products. In addition to the introduction of policies to clearly support the promotion and application of degradable plastics, it is also necessary to clearly specify the recycling and disposal of such materials and products at the legal level, and improve the standardization of the degradable plastics industry.

(2) Find out the bottom number and reasonably set the recovery target value

Coordinate the relevant departments, unify the statistical caliber and statistical methods, and effectively find out the production amount, type, flow direction, and content of waste plastics in domestic waste, etc., and reasonably set the recycling target value according to local conditions. The component monitoring of domestic waste is an important way to master the data of physical components, moisture content and calorific value of domestic waste, which is the basis for reasonably setting the target value of waste plastic recycling, and provides decision-making data support for further promoting the waste classification work. Taking Guangzhou as an example, according to the long-term monitoring data of waste components in Guangzhou, the source of recyclable waste plastics accounts for 5.93%. According to the estimate of 22,000 tons of daily domestic garbage in 2019, the source is about 1,300 tons of waste plastics with recycling potential, of which polyethylene is the main one, accounting for 84.17%, followed by polypropylene, accounting for 10.02%. Rubber and plastics accounted for 22.04% of the total, and 4,849 tons of waste plastics entered domestic waste treatment facilities every day. Domestic high-value waste plastics such as beverage bottles are recycled through the recycling system of renewable resources, however, most low-value waste plastics cannot be effectively classified and collected and properly disposed of due to various types, different forms, difficulties in distinguishing, pollution and other reasons. Further find out the types and quantity of waste plastics, especially the production of low-value waste plastics, assess their recycling feasibility, and rationally plan the recycling target value, such as setting the target value of the proportion of waste plastics entering the domestic waste incineration plant and the target value of zero waste plastics landfill, so as to promote the recycling and utilization of waste plastics.

(3) Implement the extended responsibility system for producers and their stakeholders

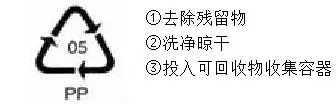

Clarify the responsibilities and obligations of plastic products producers, sellers and consumers in recycling, improve the responsibility extension system of producers and their stakeholders: first, improve the "recyclability" label management system, and identify plastic products containing recycling; The second is to establish a "recyclability" classification standard, according to the difficulty of recycling waste plastics classification, indicating waste plastic materials, cleaning and cleaning steps (Figure 1, Figure 2); Third, according to the "recyclability" level of taxation, the tax fee is used to subsidize enterprise recycling, processing, recycling processing expenses, and can also be used to subsidize the purchase of recycled plastic products with recycling labels; The fourth is to refine the responsibility of producers, sellers and consumers of recycling and recycling plastic products, and promote the whole life cycle management of plastic products.

FIG. 1 Detailed illustration of PET bottle recycling mark

FIG. 2 Detailed illustration of PP lunch box and bottle recycling mark

(4) Establish a traceability and certification system for waste plastics recycling and utilization

The government has guided industry associations to establish a traceability and certification system for waste plastic recycling and recycling, and certified the recycled plastic content and safety of recycled plastic products according to the "recyclability" label standard. It is recommended to establish a waste plastics recycling and recycling certification alliance in China, all laboratories with relevant national certification can apply to join, after passing the audit, the content and safety of recycled products can be checked, the establishment of product files to record color, related physical and chemical properties and content data, and evaluate whether it meets the relevant standards and specifications, if the test is qualified, It will announce to the outside world that the product has passed the safety certification, and allow the product to be marked with the identification mark. The waste plastic recycling traceability and certification system will be conducive to the development of green procurement lists, promote the construction of resource-saving and environmentally friendly society, promote green circulation and sustainable development, and guide government units and enterprises to actively participate in the implementation of green procurement policies.

5. Increase policy funding support

Although most cities in China have introduced low-value recyclable catalogs and related management methods, the catalog also covers shampoo and shower gel cans, oil cans, soy sauce cans, plastic buckets, plastic stools, flower POTS, trays, felt and other low-value waste plastics, but the policy subsidies are small, the cost is high, the tax is high, the profit is limited, and the enterprise operation is under pressure. The scope of subsidies for low-value recyclables should be increased, subsidies and tax preferential policies should be introduced, and the waste plastic recycling traceability and certification system should be used as evidence of the source of waste plastics and the subsidy policy should be implemented, so as to guide enterprises to actively participate in the recycling of low-value plastics and reduce the pollution of waste plastics to the environment.

(6) Improving the construction of the whole process of recycling and utilization

Relying on the integration of the two networks and the integration of cleaning and cleaning operations, convenient recycling points are set up in residential communities, and conditional sanitation facilities such as transfer stations, sanitation public toilets, sanitation tool houses, and garbage collection stations are encouraged to add convenient recycling points without affecting the function of the original facilities. Streets and towns will coordinate the establishment of temporary storage points, and districts and counties will coordinate the construction of recycling sorting centers. Establish a waste plastic recycling and utilization network integrating the two networks of put-collection-transport-distribution and recycling, ensure the construction land of the network, maximize the recovery of resources and save costs.

(7) Cultivating leading enterprises to form scale effects

By supporting leading enterprises in the recycling and utilization of waste plastic renewable resources, improving the utilization rate of waste plastic recycling through large-scale and intensive, improving enterprise operating standards and reducing costs. Support and guide recycling enterprises to enter industrial parks and domestic waste treatment parks. Encourage enterprises to promote cleaner production, promote technological upgrading, and improve the management and employment level of the recycling industry.

8. Increasing investment in scientific research

The current treatment technology and utilization of various waste plastics have their advantages and disadvantages, and can not independently achieve the purpose of recycling, reducing and harmless waste plastics treatment. Therefore, increase investment in scientific research, improve the existing waste plastic treatment technology, research and development can independently achieve the "three" waste plastic treatment of new treatment technology, the production of higher value-added products, while strengthening the balance of enterprise resources and the market. The government has increased funds to support the research and development and innovation of degradable plastics, and it is still necessary to reduce the production cost of lactic acid in the future, expand the production capacity and reduce the cost of succinic acid and 1, 4-butanediol. Foster a good industrial environment and encourage advanced enterprises to participate in research and development. Guide enterprises to actively carry out deeper industry-university-research cooperation with universities and research institutes, and develop degradable plastics with excellent performance and economic benefits to replace non-degradable plastics.

(9) Implement residents' responsibility for garbage classification

Strengthen the publicity and guidance of residents, rough cleaning of waste plastics before recycling, the use of special bucket recycling, regular recycling and other modes, to strengthen the habit of residents. In the process of promoting the four classifications, the fine classification of recyclables can be promoted in the area where conditions are available to reduce the confounding degree of recyclables, improve the purity of resources, and improve the recycling efficiency.

(Source: Guangzhou City Management Technology Research Center contributed by Su Ying)