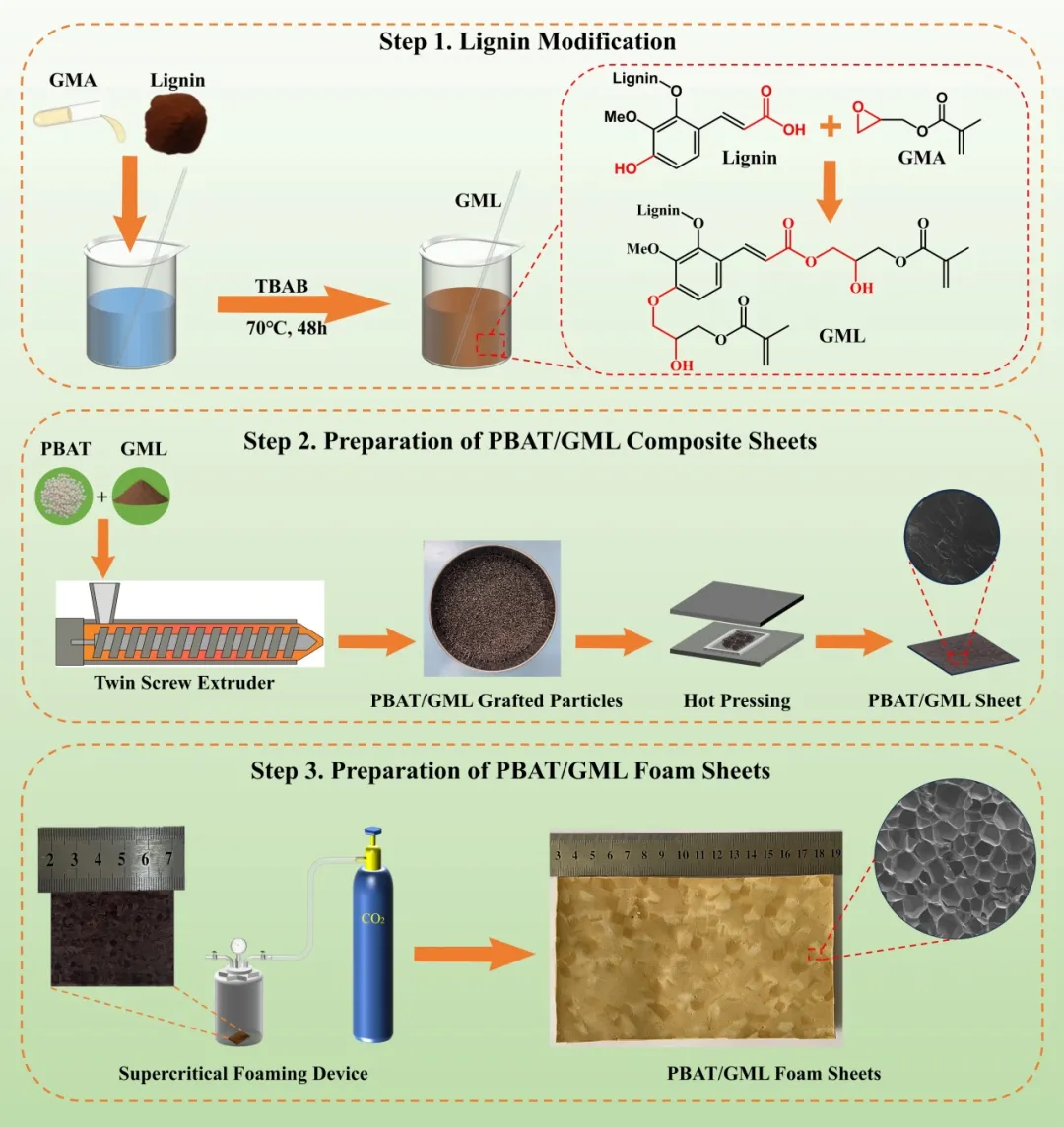

As one of the mainstream biodegradable materials, butanediol phthalate adipate (PBAT) foam provides a degradable substitute for traditional plastic foam and effectively reduces environmental pollution. However, the high cost and poor mechanical properties of PBAT foam hinder its practical application. Therefore, it is a very attractive and important research to manufacture PBAT foam with high mechanical properties through green and low-cost strategies. Based on the above background, Professor Zhu Chenjie's team from Nanjing University of Technology prepared PBAT/ Modified lignin (PBAT/GML) composite foam with good foaming and mechanical properties under high wood mass filling by using free radical polymerization and supercritical CO2 foaming process (FIG. 1).

FIG. 1 Schematic diagram of PBAT/GML composite foam prepared by lignin modification and supercritical carbon dioxide foaming

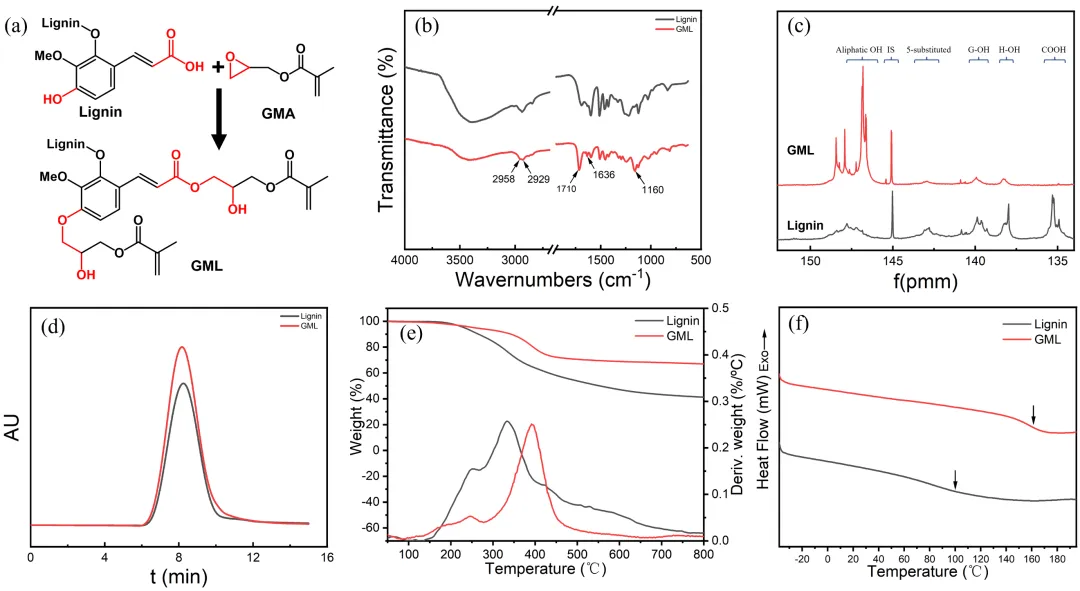

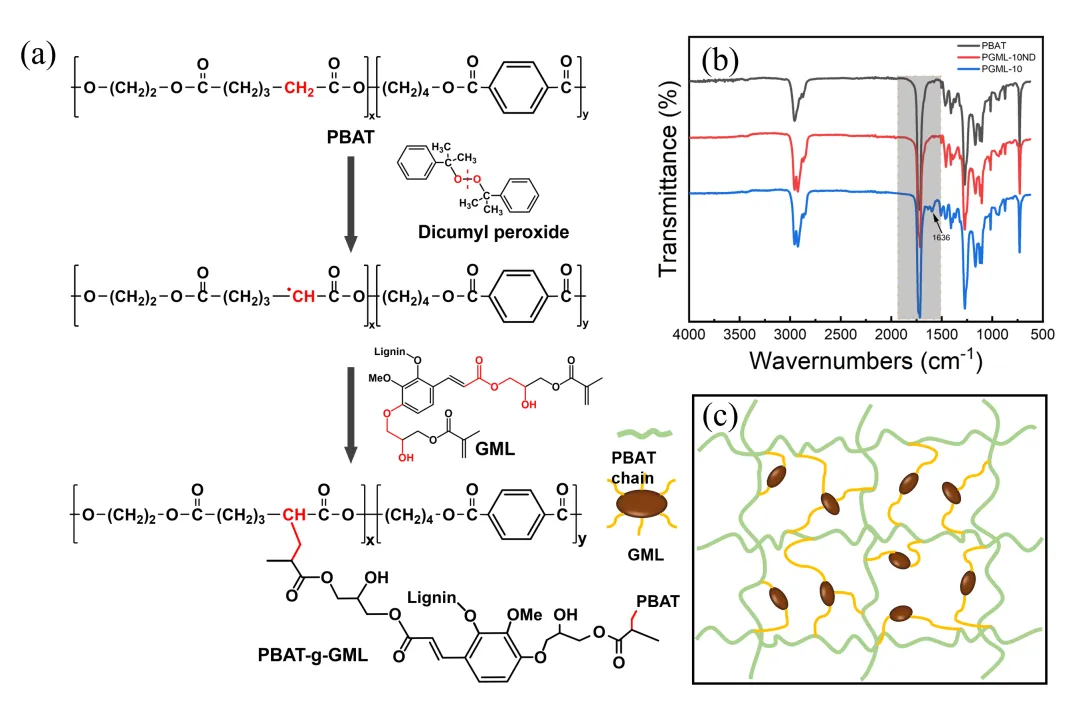

Researchers synthesized modified lignin (GML) by grafting glycidyl methacrylate (GMA) on lignin (FIG. 2, FIG. 3), endowed GML with double bond crosslinking groups, and formed ester bonds to improve the compatibility of GML and PBAT. Figure 2. (a) Esterification modification of lignin by GMA; (b) FTIR spectra, (c) 31P NMR spectra, (d) GPC curves, (e) TG and DTG curves, and (f) DSC curves of primary lignin and GML

Figure 2. (a) Esterification modification of lignin by GMA; (b) FTIR spectra, (c) 31P NMR spectra, (d) GPC curves, (e) TG and DTG curves, and (f) DSC curves of primary lignin and GML

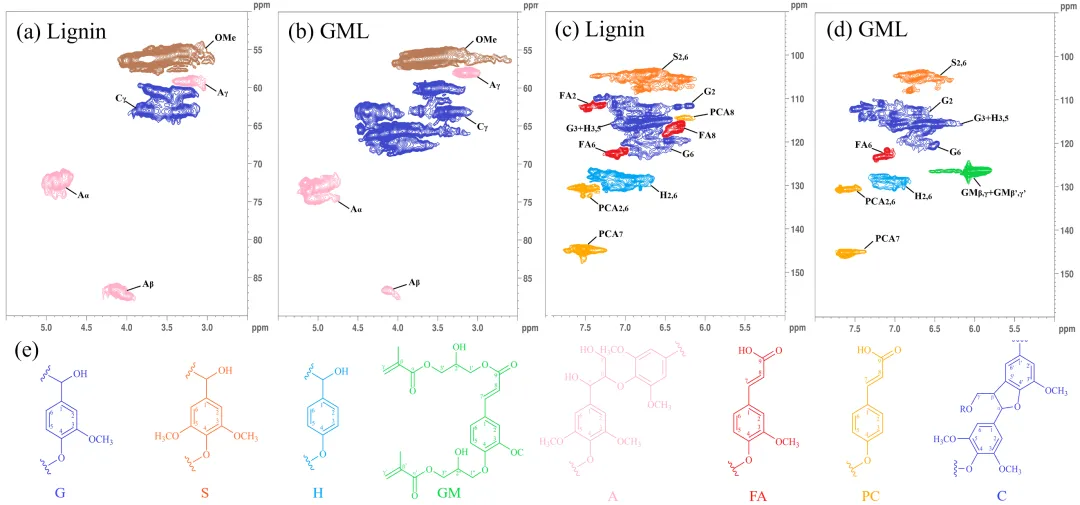

FIG. 3 2D-HSQC spectra of raw lignin and GML showed (a, b) aromatic region and (c, d) fatty region. (e) Primary lignin and major substructural units of GML

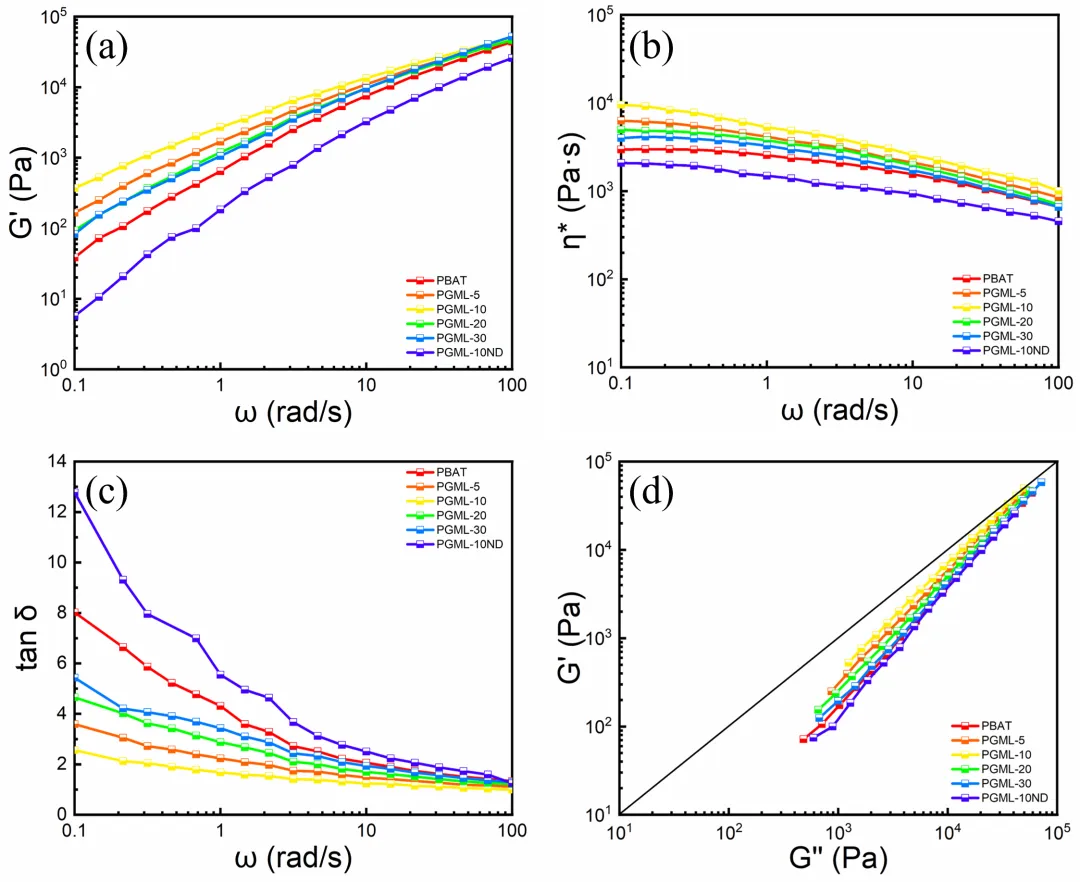

PBAT/GML (PGML) composites were prepared by twin-screw melt extrusion process using PBAT and GML. The double bonds of GML can undergo radical polymerization with PBAT and form a covalent cross-linked network, which hinders the thermal decomposition of the material and improves the thermal stability of the composite material (Figure 4). Rheological analysis results show that the introduction of GML can increase the melt strength of the polymer, promote the foaming properties of PGML composites, and improve the strength and stability of the composites (FIG. 5). Figure 4: (a) DSC cooling curve, (b) DSC secondary heating curve, (c) TG curve and (d) DTG curve of PBAT, PGML and GML samples

Figure 4: (a) DSC cooling curve, (b) DSC secondary heating curve, (c) TG curve and (d) DTG curve of PBAT, PGML and GML samples

Figure 5. (a) energy storage modulus, (b) viscosity, (c) tanδ and (d) Han diagrams of PBAT and PGML composites

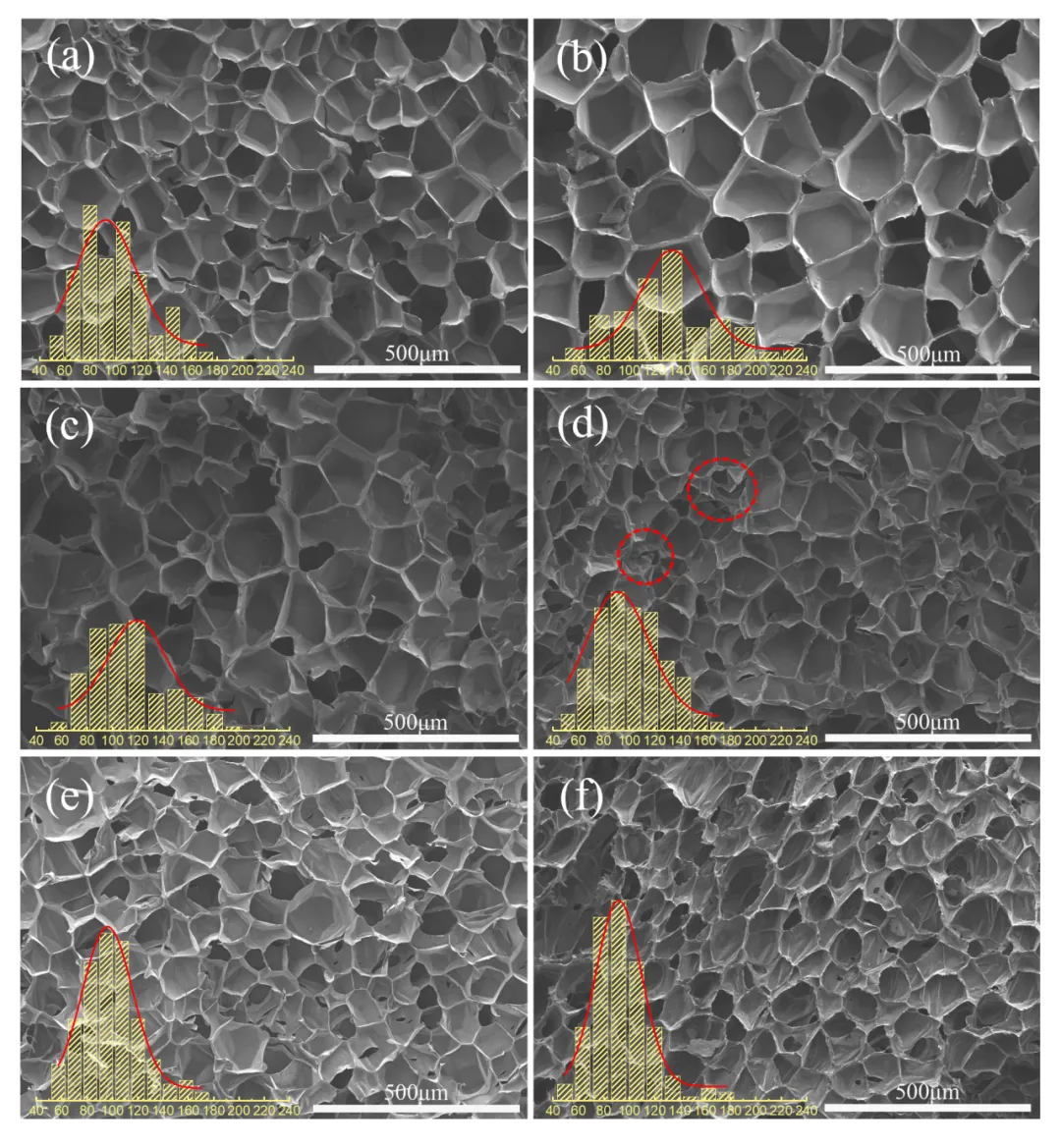

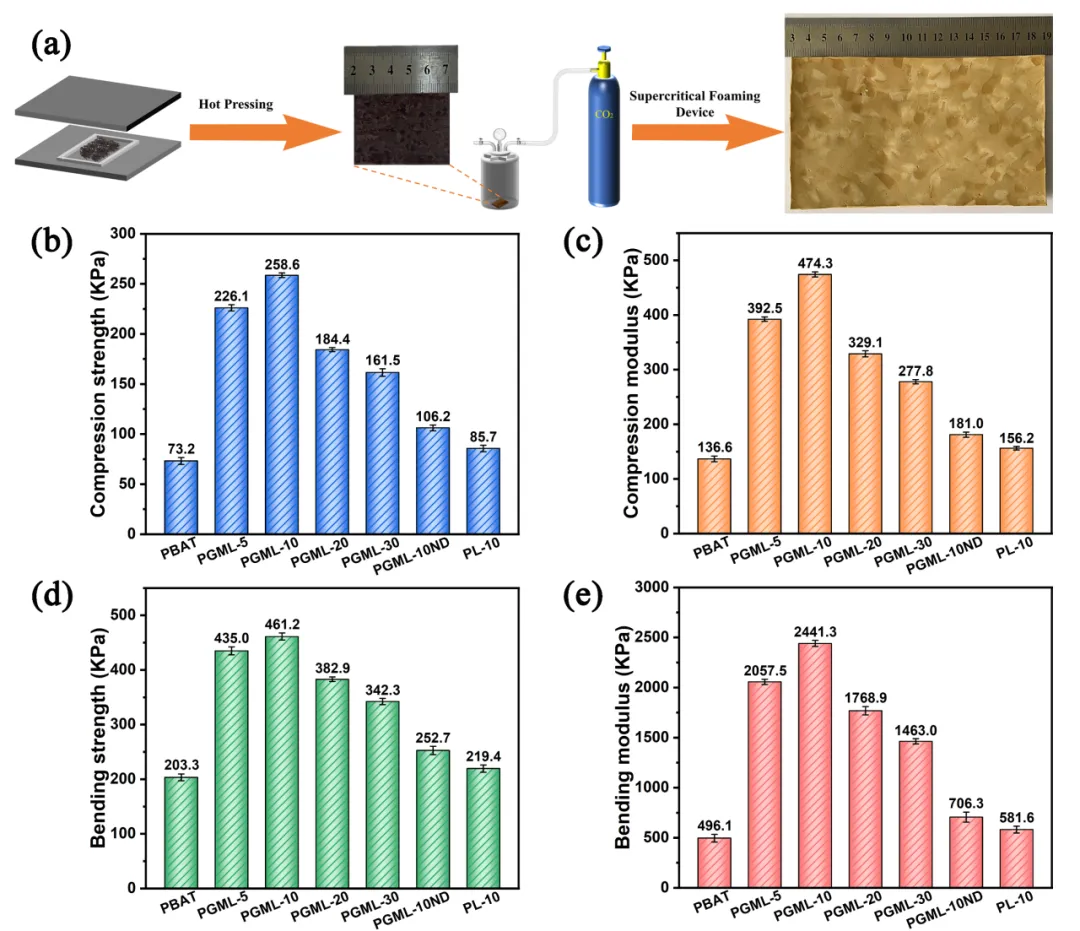

Through further supercritical CO2 foaming, PGML composite foam with good foaming properties and high mechanical properties was prepared (FIG. 6-8). The results of morphological analysis showed that the pore structure of PGML composite foam was relatively complete when the GML content was less than 20%. After adding GML, the compressive strength and compressive modulus of PGML foam were significantly improved. Compared with PBAT, the compressive strength of PGML-10 is increased by 2.53 times, and the compression modulus is increased by 2.47 times. In addition, because GML increased the crosslinking density of PBAT matrix and improved the stress energy dissipation, the bending strength and bending modulus of PGML-10 were increased by 1.27 times and 3.92 times, respectively. Figure 6 Cell morphology and pore size of different composite foams: (a) PGML-5, (b) PGML-10, (c) PGML-20, (d) PGML-30, (e) PGML-10ND and (f) PL-10

Figure 6 Cell morphology and pore size of different composite foams: (a) PGML-5, (b) PGML-10, (c) PGML-20, (d) PGML-30, (e) PGML-10ND and (f) PL-10 Figure 7. (a) Schematic diagram of preparation of PGML composite foam; (b) compressive strength, (c) compressive modulus, (d) bending strength and (e) bending modulus of PBAT and PGML composite foams

Figure 7. (a) Schematic diagram of preparation of PGML composite foam; (b) compressive strength, (c) compressive modulus, (d) bending strength and (e) bending modulus of PBAT and PGML composite foams

FIG. 8 (a) Schematic diagram of the reaction mechanism between GML and PBAT; (b) FTIR spectra of PBAT, PML-10ND and PML-10 after Soxhlet extraction; (c) Cross-linked network diagram formed by GML and PBAT

This study provides a new idea for the development of low-cost biodegradable PBAT/ Lignin composite foams with good foaming and mechanical properties. Xu Hongsen, a master's student in the School of Biological and Pharmaceutical Engineering, Nanjing University of Technology, is the first author of the paper, and Professor Zhu Chenjie and Lecturer Chang Zhiwei are the corresponding authors. This research was supported by the National Natural Science Foundation of China (22378195 and 22178170), the National Key Research Program Project (2021YFC2102805), and the Jiangsu Youth Science Foundation (BK20210145).