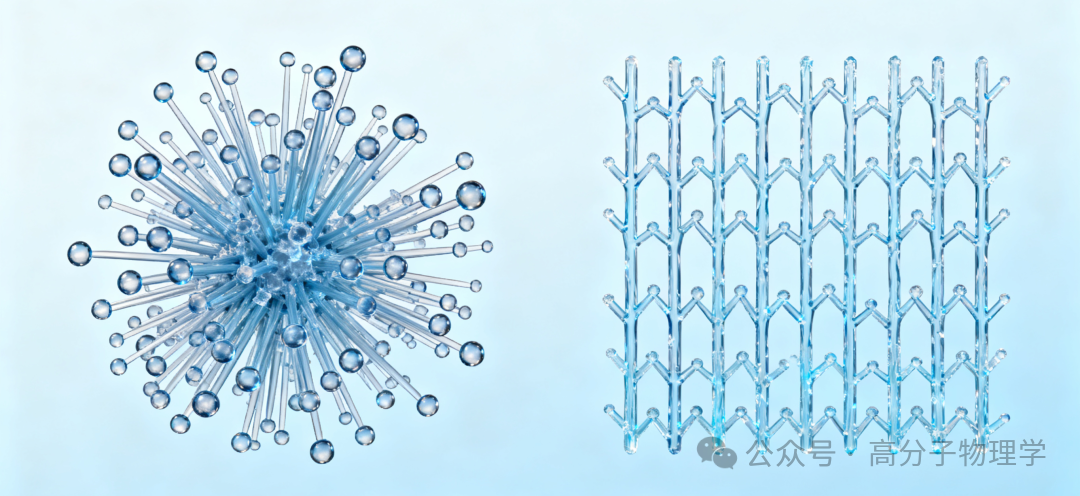

Polylactic acid is a new type of biobased degradable material. It is a high molecular polymer formed by the glycation, fermentation and polymerization of renewable plant resources (such as corn and straw). Polysaccharides in crops, such as starch, cellulose and hemicellulose, are decomposed into monosaccharides like glucose through various biological enzymes; then, through biological fermentation technology, using microorganisms (such as lactic acid bacteria) for fermentation, lactic acid is produced, which is purified and processed to obtain high-purity L-lactic acid; and then, using chemical synthesis technology, the high-purity L-lactic acid is polymerized into high-molecular-weight polylactic acid.

In 2020, the National Development and Reform Commission and the Ministry of Ecology and Environment jointly issued the "Opinions on Further Strengthening Plastic Pollution Control", which triggered the market for biodegradable materials. PLA gradually became known to the public.

In recent years, with the continuous enhancement of people's environmental awareness and the implementation of plastic restriction and prohibition policies in various regions, the bio-based degradable material industry has been constantly developing. Among them, the research on polylactic acid (PLA) and the expansion of its downstream applications have also attracted much attention, and it has increasingly become one of the most fully developed, with the best performance, and having the most promising application prospects among bio-based degradable materials. We have summarized the following advantages of polylactic acid:

Excellent processing performance

Polylactic acid has excellent processing properties and a wide range of applications. It can be processed into various products through various techniques such as extrusion, stretching, blow molding, thermoforming, blow film making, laminating, foaming, and spinning, just like traditional petroleum-based plastics. The processing temperature is relatively low, and no additives need to be added during the processing. The production cost is also low.

2. Excellent biodegradability

PLA is relatively stable at room temperature, but it is prone to rapid degradation into CO2 and water under slightly elevated temperature conditions, acidic or alkaline environments, and microbial conditions. Therefore, by controlling the environment and the filler, PLA products can be made safe for use within the specified period, and they can also be promptly degraded after disposal.

3. Safe biocompatibility

The synthetic monomer of PLA, L-lactic acid, is a common chemical substance in the metabolic pathways of living organisms (including humans). Enzymes capable of metabolizing L-lactic acid are also present in living organisms. Therefore, PLA has extremely high biological safety. Some researchers have conducted PLA animal implantation experiments, and the results show that PLA has no toxic effects on animals and can complete degradation in the biological environment.

4. Environmentally friendly and low-carbon green materials

The raw materials of PLA come from renewable starch-based materials produced through photosynthesis (such as corn, cassava, sugar cane, etc.). It can achieve a self-closed system of "carbon sequestration during planting - carbon emission during fermentation - carbon emission during production - carbon decomposition", significantly reducing the carbon emissions from the current petroleum-based plastic production process. Therefore, in the context of the global "carbon strategy", PLA has a "carbon advantage" compared to resins produced from traditional petrochemical raw materials.

5. Widespread application fields

Based on these advantages, polylactic acid has demonstrated its unique and distinctive applications in various fields, and this trend is still being continuously explored.

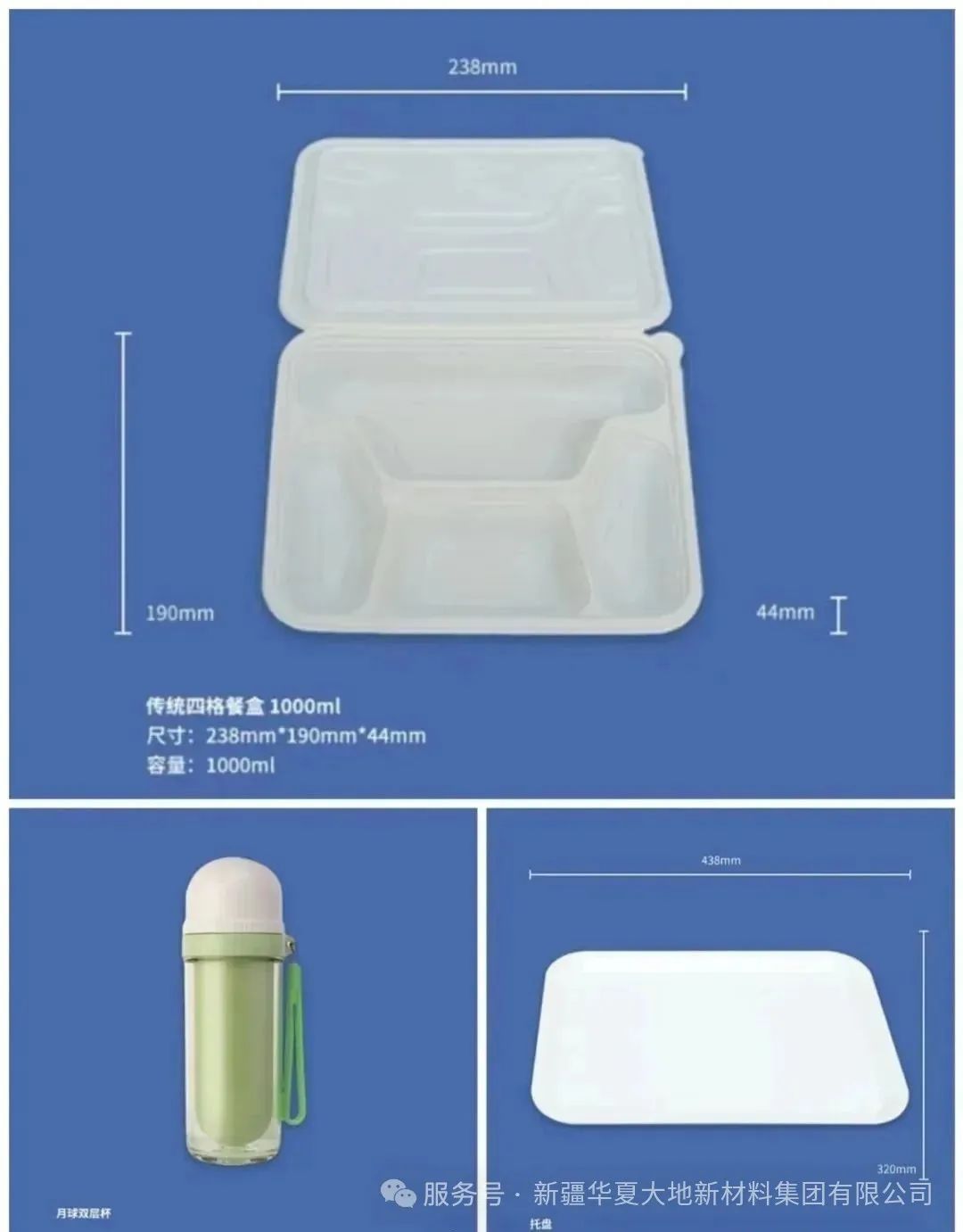

In terms of film and sheet extrusion: For high-transparency film and sheet products, the raw material is mainly polylactic acid, and the temperature resistance is generally around 55℃; for non-transparent film and sheet products, the raw material needs to be modified to achieve high temperature resistance, which is generally above 100℃.

Injection molding: Injection-molded tableware is mostly used in durable consumer goods. After modification, the PLA products can withstand temperatures above 100℃. Therefore, polylactic acid can be used to produce various plastic products through injection molding, such as children's tableware, etc.

In terms of fibers: Polylactic acid is a new type of polyester material, featuring environmental friendliness, non-toxicity, degradability; antibacterial, antimalarial, anti-allergy; skin-friendly, flame-retardant, non-hygroscopic, and UV-resistant. The fabric made of polylactic acid has good dimensional stability, combining the comfort of cotton, the draping of viscose, the strength of polyester and the hand-feel of silk. It is widely used in clothing, home textiles, and medical products, and is currently a very promising "green fiber".

In terms of fibers: Polylactic acid is a new type of polyester material, featuring environmental friendliness, non-toxicity, degradability; antibacterial, antimalarial, anti-allergy; skin-friendly, flame-retardant, non-hygroscopic, and UV-resistant. The fabric made of polylactic acid has good dimensional stability, combining the comfort of cotton, the draping of viscose, the strength of polyester and the hand-feel of silk. It is widely used in clothing, home textiles, and medical products, and is currently a very promising "green fiber".

Foaming aspect: PLA foaming is divided into extrusion foaming and pellet foaming. It is applied in various fields such as catering packaging (such as food boxes, heat-insulating cups, instant noodle bowls, which have the characteristics of heat preservation and insulation), cold chain insulation packaging (used for cold chain transportation, takeout insulation delivery, etc., capable of producing foldable cardboard boxes, with good insulation effect), internal cushioning packaging for luxury goods, alcoholic beverages, etc. (with good product support, better cushioning and protection effect than general PET blister, cardboard, plant fiber molded products, and the packaging is lighter, which can overall reduce the product weight and thus save costs), supermarket packaging (PLA foaming products are also widely used in supermarket fresh food packaging, such as making meat trays, which can be frozen, thawed by microwave, and can absorb water; for fragile products, it also has excellent protective performance).

In terms of membranes: When the blending ratio of membrane bag materials with PBAT (for shopping bags, garbage bags, etc.) is higher, the mechanical processing performance becomes more stable; the lower the weight per unit area of the membrane bag, the lower the cost; the better the gloss and hand feel of the membrane bag, and the stronger its strength; the shelf life of the product is longer.

Bidirectional stretching die: Through adjustments and control of raw materials and processes, single or bidirectional stretching can be achieved, as well as heat sealing functions. The products have excellent transparency and excellent display properties, and are widely used in beverage bottle labels, food packaging, can packaging, and electronic products, etc.; it is also a high-quality raw material for degradable tapes and cigarette films. In addition, polylactic acid can also be developed and produced into polylactic acid polyols, which can be used as raw materials for polyurethanes.