Amid the rampant plastic waste, although the biodegradable plastic poly(lactic acid) (PLA) is highly anticipated, it is confronted with the problems of slow industrial composting degradation and difficult monomer recovery. Recently, a study by the Italian Institute of Technology found that the lipase secreted by Aspergillus oryzae can efficiently decompose PLA materials under mild conditions, providing a green new solution to the problems of PLA degradation and lactic acid recovery.

Bottlenecks in Industrial Composting: Dual Challenges of Efficiency and Recycling

As the most widely used biobased plastic at present, PLA is produced by fermentation of crops such as corn and sugar cane. In theory, it can decompose into water and carbon dioxide in a composting environment. However, in reality, it takes 12 weeks to degrade at a high temperature of 60 - 65℃ and a humidity of 60% in an industrial composting environment. Moreover, it cannot recover the lactic acid monomers, which makes composting plants that are accustomed to handling natural organic matter less receptive to it. How to make PLA degrade more quickly while achieving resource recycling has become the key to industry breakthroughs.

Enzymatic degradation new solution: Precise attack + Gentle conditions

Mucor racemosus, as a commonly used safe fungus in the food industry, secretes lipases that are non-toxic and can be produced on a large scale.

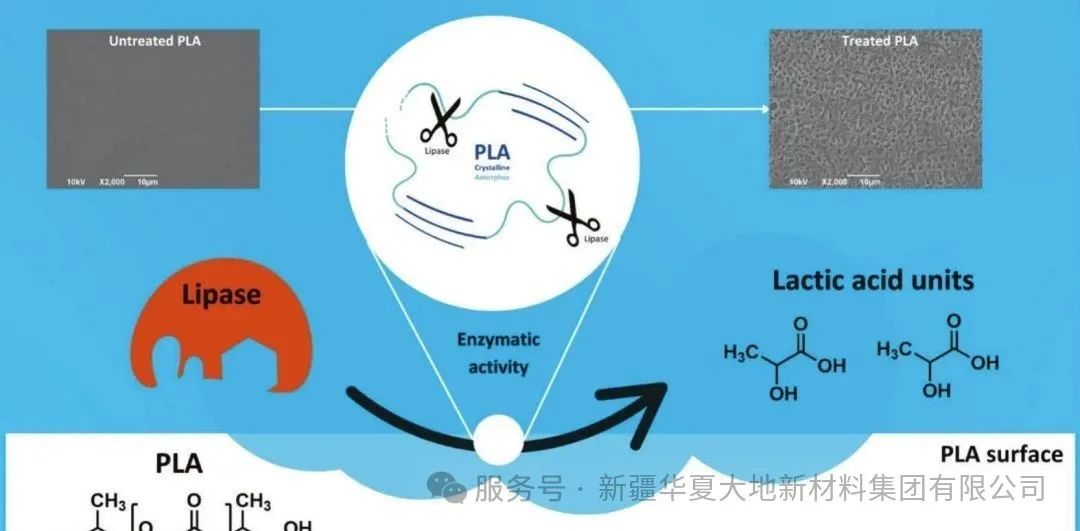

The research team selected the commonly used Aspergillus oryzae lipase in the food industry and conducted experiments in a neutral to slightly alkaline environment at 37℃ (close to human body temperature). The results showed that when the pH value was adjusted to 8.0, the lipase acted like "molecular scissors", precisely cutting the ester bonds in the amorphous regions of PLA, while preserving its crystalline structure. Under a microscope, it could be observed that the surface of the treated PLA film became rough and porous, with significantly enhanced hydrophilicity. This meant that more enzyme molecules could come into contact with the polymer chains, accelerating the degradation process.

More importantly, as the enzyme concentration increases, the degradation rate of PLA films and particles significantly accelerates. High-performance liquid chromatography analysis confirmed that during the degradation process, a large amount of lactide monomers were released - these "building blocks" can be re-polymerized into new PLA, truly achieving a "closed loop from nature to nature".

This is the first report on the enzymatic degradation of PLA components using Aspergillus oryzae lipase, which has paved the way for accelerating biodegradation and proves that composting can serve as a feasible end solution for bioplastics.

Meanwhile, the recovery of lactic acid enables chemical recycling, which can be used to synthesize new PLA, promoting the development of the circular economy and providing new ideas and methods for solving the terminal processing problems of PLA materials and promoting the application of sustainable bioplastics.