Corn stalks are often discarded due to their low utilization rate, resulting in significant waste of resources. Therefore, it is of great significance to utilize waste materials and abundant whole corn as raw materials to replace petroleum resources.

By utilizing agricultural and forestry waste such as corn and straw for bio-refining, high-quality, safe and degradable new materials can be produced. The polylactic acid made from straw has excellent biocompatibility, mechanical properties and thermal stability. It shows broad application prospects in numerous fields such as packaging, textiles and medicine. It is like a new emerging star material, gradually revealing its mysterious veil and moving towards a wider market and life scenarios with a sustainable development attitude. This helps to achieve the 'dual carbon' goals of carbon neutrality and carbon peak.

What is polylactic acid?

Polylactic acid particles (PLA) are the only biodegradable polymer material that is produced by microbial fermentation using starch-containing biomass such as corn and straw as raw materials, and then through polymerization processes. This material has the characteristics of being environmentally friendly, non-toxic, and having good biocompatibility. After being discarded, it can decompose into carbon dioxide and water under composting conditions and is widely used in packaging, medical implants, and textile industries.

What are the uses of polylactic acid?

Polylactic acid is a new type of biodegradable material, widely used in various fields such as extrusion, injection molding, film pulling, and spinning. It is processed into products for clothing, food packaging, tableware, agricultural mulch films, seedling trays, disposable infusion tools, self-sealing surgical sutures, drug relief packaging agents, artificial fracture internal fixation materials, tissue repair materials, artificial skin, building materials, and even automotive parts, covering multiple industries and product categories.

How is polylactic acid from straw produced?

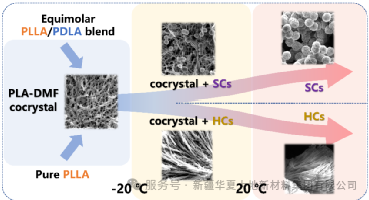

The production of bioplastic from straw begins with the pre-treatment of the collected straw, which involves removing impurities and then grinding it to an appropriate particle size. Next, through a hydrolysis process, under the action of specific microorganisms, the cellulose and hemicellulose in the straw are decomposed into sugar substances. Then, using microbial fermentation technology, the sugars are converted into lactide monomers. Subsequently, the lactide monomers are purified to remove impurities and increase purity. Finally, through a condensation reaction, under the action of a catalyst, the lactide monomers undergo polymerization to form a straw-based polylactic acid polymer. After further processing, the desired straw-based polylactic acid product can be obtained.

What are the market values of straw-based polylactic acid?

From an environmental protection perspective, it uses straw as the raw material, effectively solving the problem of straw disposal and reducing environmental pollution. This aligns with the global sustainable development concept, making it highly favored in the international environmental protection market.

In terms of performance, polylactic acid has excellent biodegradability, mechanical properties and processing properties, and can be widely applied in various fields such as packaging, textiles, and medicine.

The packaging industry has witnessed a significant increase in demand for environmentally friendly packaging materials. Stalk-based polylactic acid can perfectly replace traditional non-degradable materials; the textile industry is seeking sustainable fibers, which can become new raw materials for textiles; in the medical field, there is a huge demand for products such as absorbable sutures, and their biocompatibility precisely meets this demand.

With the enhancement of consumers' environmental awareness and the stricter environmental policies of various countries, bagasse polylactic acid, due to its unique advantages, has great market potential and is expected to occupy an important share in the future market, generating considerable economic benefits.