Recently, it was reported that Pirelli has announced that it will exclusively supply three custom tires for the new McLaren W1 super sports car. It has been verified that the proportion of bio-based and recyclable and reusable materials in these three tires exceeds 50%, setting a new record for high-performance supercar tires.

McLaren W1 Super Sports Car

McLaren W1 Super Sports Car

This series of tires is specifically designed to handle the power output of W1, which reaches up to 1275 horsepower, as well as the extreme downforce. This marks the practical application capability of bio-based materials in high-stress and high-safety requirements industrial scenarios. Pirelli plans to launch tire products with a sustainable material content of 80% by 2030.

According to incomplete statistics from Artery Network, apart from McLaren, automakers such as Mercedes-Benz, BMW, Volkswagen, Toyota, General Motors and NIO are all engaged in the development of bio-manufacturing. From these layouts, we can see the three major characteristics that major automakers favor bio-manufacturing.

"Advantage of being renewable raw materials."

This is the most direct driving factor. Biomanufacturing uses plants (marijuana, bamboo, flax) or microorganisms as raw materials, replacing petroleum and animal fur. Among them, the mass-produced industrial hemp leather, the natural fiber composite materials of BMW/Mercedes-Benz, and the plant protein materials of Mercedes-Benz all directly reflect the idea of replacing non-renewable resources with renewable biomass.

2. "Advantages of Process Low Carbonization"

Biological manufacturing processes (especially fermentation) typically have lower energy consumption and carbon emissions compared to traditional petrochemical processes. The biological-based materials themselves also absorb carbon dioxide during their growth. Some automakers have chosen biological-based polyamide (such as Toyota's PA56) or mycelial materials (such as General Motors'), not only using the final materials but also injecting low-carbon attributes throughout the product lifecycle, helping automakers reduce indirect carbon emissions.

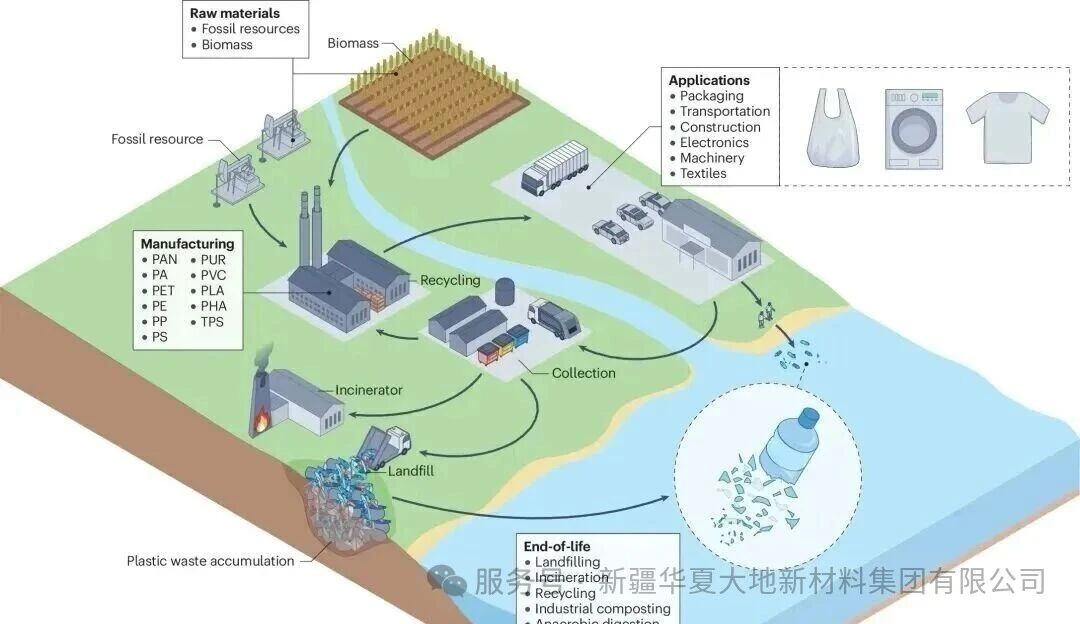

3. "Advantages of the Circular Economy"

Some bio-based materials are degradable. What's more, the biological enzymatic degradation technology can precisely disassemble and reuse materials that are difficult to recycle traditionally (such as mixed fabrics). For instance, Toyota carried out enzymatic degradation to recover the safety airbag fabric, breaking away from the traditional physical recycling and downgrading utilization model and achieving a chemical-level closed-loop cycle.

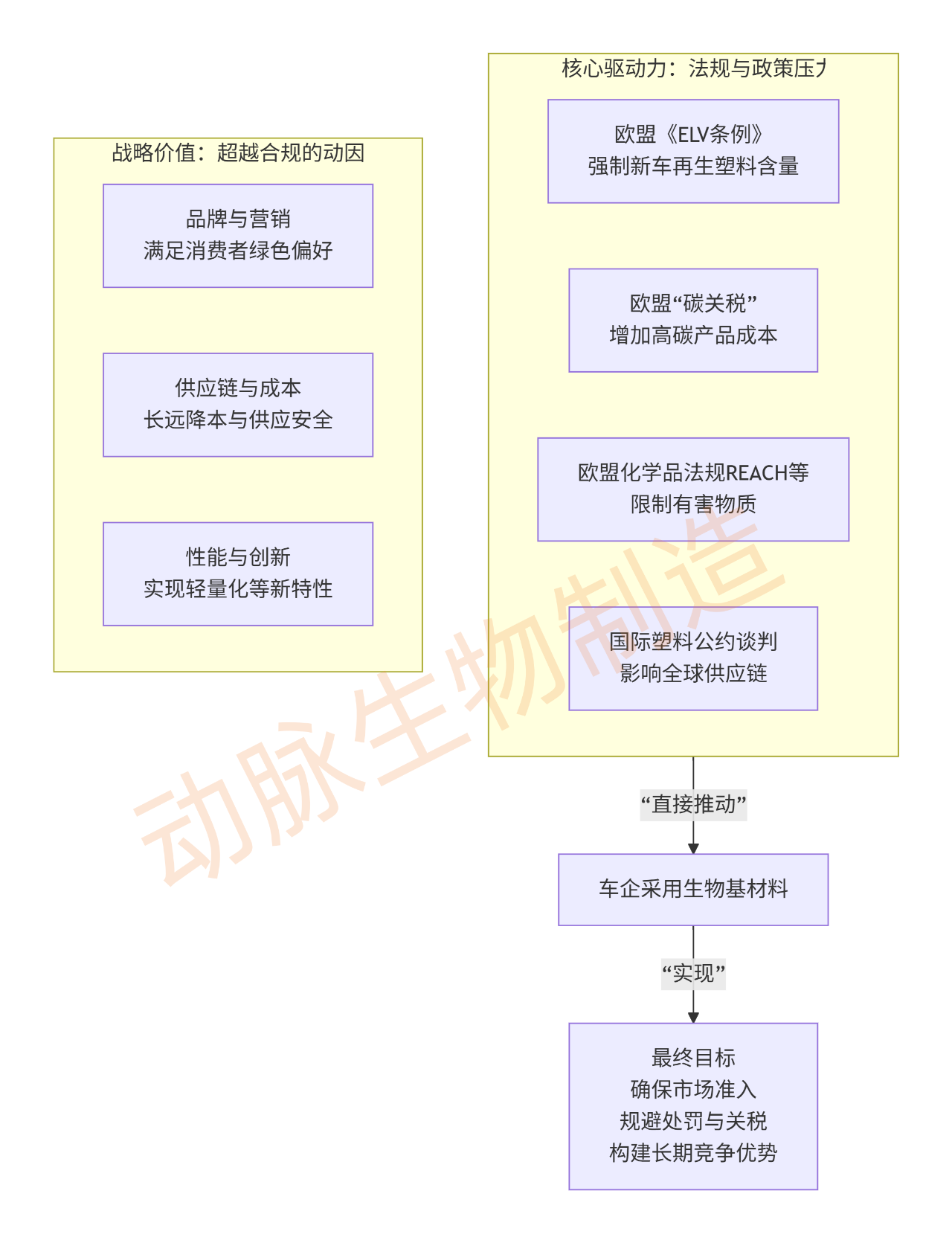

From this perspective, the fact that major automakers are placing such emphasis on bio-manufacturing may be driven by the pressure of carbon neutrality and sustainable development.

It is known that a significant portion of the carbon emissions in the automotive industry come from the supply chain, especially from traditional petroleum-based plastics, rubber, fabrics, etc. Biobased materials (such as those extracted from corn, sugar cane, plant fibers, and waste cooking oil) absorb carbon dioxide during their growth process. The carbon footprint throughout their entire lifecycle is usually much lower than that of petrochemical materials. This is a crucial step for automakers to achieve the goal of "full lifecycle carbon neutrality".

Moreover, environmental regulations in major global markets (especially in the EU and China) are becoming increasingly stringent. For instance, the "European Green Deal" and the Carbon Border Adjustment Mechanism (CBAM) in the EU have set strict requirements for the carbon content of products. Using bio-based materials might be a pragmatic move for automakers to comply with regulations, avoid penalties or tariffs.

In addition, major automakers also need to fulfill their ESG (environmental, social, governance) commitments. Investors and the capital market are increasingly paying attention to a company's ESG performance. Using renewable materials is an effective way to demonstrate its environmental responsibility, enhance its brand image, and obtain green financing.

If these factors are the main driving forces behind it, then the application of biomanufacturing technology in the automotive industry may be difficult to achieve on a large scale in the short term. This is because environmental friendliness is an additional advantage of biomanufacturing rather than a core advantage.

A senior investor in the field of bio-manufacturing told Aion Network that bio-manufacturing is moving from a laboratory concept to the industrialization battlefield, and its core commercialization path has become increasingly clear. In the past, the industry was driven by "green stories", but the real breakthrough lies in two pragmatic paths:

First, by leveraging absolute cost and efficiency advantages to replace existing solutions. For instance, by applying synthetic biology technology, the production cost of certain chemical products can be reduced by over 50%, or the production efficiency can be increased by several times;

Second, it enables the accomplishment of tasks that traditional methods cannot achieve, such as the efficient synthesis of structurally complex natural products, or the large-scale production of high-value components with extremely low production capacity through traditional fermentation methods, thereby opening up new markets.

The current market perception is also returning to the core of the industry - cost and value. Products that relied on "biodegradable" and "ESG concepts" in the past often failed to compete with mainstream solutions in terms of cost and thus often ended up being merely "image projects".

The aforementioned investor further analyzed to ATEM: The true industrialization requires that biological manufacturing must prove its economic viability: either directly reducing the price of the end product, or creating irreplaceable functional value at an acceptable premium. Only when the "green premium" of the technology disappears or transforms into a "performance premium" will large-scale substitution occur.

Moreover, multiple successful cases have shown that the core of applying biomanufacturing technology lies in selecting products with sufficient market capacity, and integrating the entire chain from strain construction, process scaling-up to downstream production. Ultimately, it can outperform chemical synthesis or traditional extraction in terms of cost and scale.