Li Boyang

Director of the Consumer Goods Industry Research Institute

Has long been engaged in the research on management policies for high-quality development of the consumer goods industry, green design of industrial products, and strategic decision-making for industrial green and low-carbon transformation, etc.

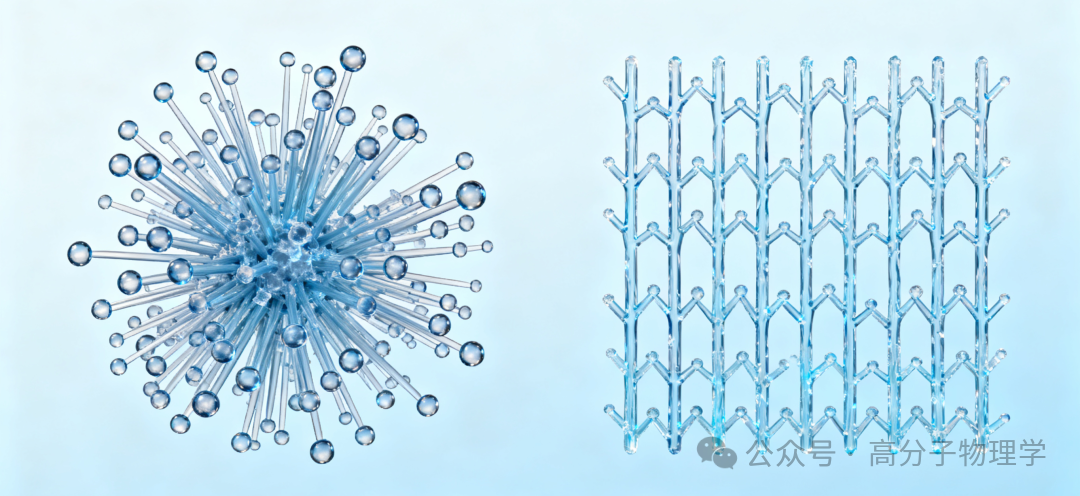

Our latest developed "Artificial Marine Carbon Cycle System" can utilize electro-catalytic technology, just like a magnet, to collect the carbon dioxide dissolved in seawater and convert it into a kind of "food" that microorganisms love to consume.

When these microorganisms have "fed" enough, they can produce the "green raw materials" commonly found in daily life, which can be used to manufacture plastic products such as straws and beverage bottles - polybutylene succinate. Currently, this system has been operating stably in real seawater for over 500 hours, with a carbon dioxide capture efficiency exceeding 70%.

The "green magic" of the biomanufacturing laboratory

Isn't it amazing that the carbon dioxide in seawater "turns into" "green raw materials"? In fact, the wonders of biological manufacturing go far beyond this. By giving microbial yeast the ability to "grow" and produce plant components, using bacteria to synthesize "intelligent living adhesives" to replace traditional "band-aids", and even transforming marine algae into energy similar to oil and coal - these scenarios that sound so novel are precisely the directions that our Chinese researchers are striving to achieve.

Behind every technology lies solid and advanced scientific research. The development process itself is fraught with difficulties. What's even more challenging is that to make these "samples" in the laboratories truly enter people's lives and become "products", the difficulty increases exponentially.

Interview: The Innovation Code Within "A Building"

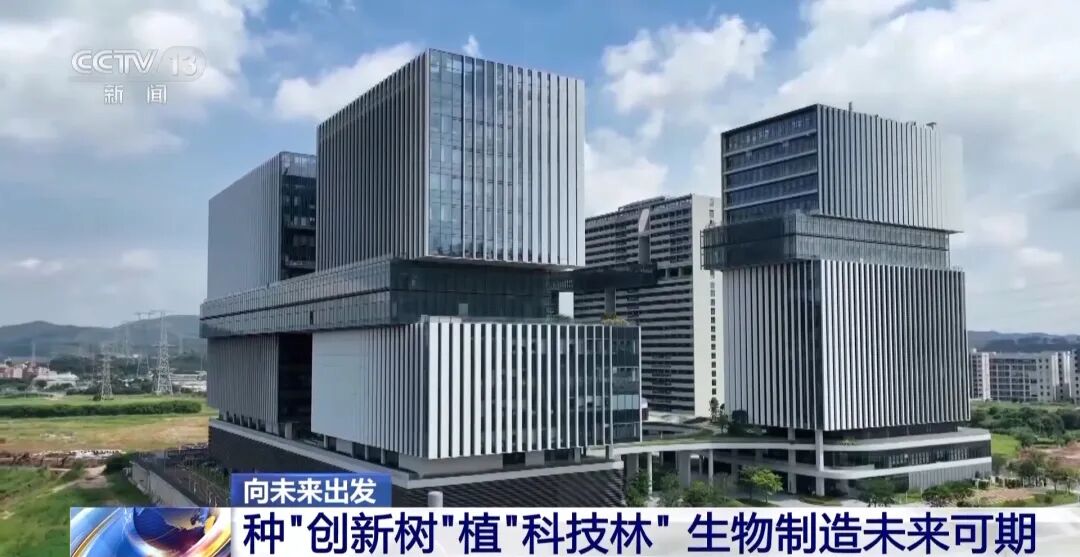

Nowadays, the country is making forward-looking plans for future industries, and various regions are also actively exploring ways to accelerate this process. Shenzhen's answer is "innovation on the upper floors and entrepreneurship on the lower floors". How exactly does this model break down barriers?

The "inspiration" from basic research is just one step away from the "demand" for industrial application. The newly developed strains in the laboratory can be delivered to the pilot testing floor the same day. When enterprises encounter problems, they can also "go upstairs" to seek cooperation with scientists.

Gao Xiang, an associate researcher at the Synthesis Institute of the Shenzhen Advanced Institute of Technology under the Chinese Academy of Sciences: Obviously, without this barrier, people often discuss what you did and what I did. This is a relatively good way.

In the past, the challenges of biomanufacturing went far beyond the science itself. Scientists had to focus on research and development while also calculating the economic costs. Now, the "up-and-down, door-to-door" innovation model not only drives breakthroughs in research and development but also opens up the key path for成果转化, enabling research and development to closely link with industries and breaking down the "research isolation". Scientists are responsible for tackling technical challenges, while entrepreneurs are responsible for promoting and applying the technologies. This has achieved an effect of "1 + 1 > 2".

At present, a complete innovation and entrepreneurship ecosystem has been established in the local area, supporting enterprises from start-up to growth and development. Thanks to this ecosystem, we have achieved such a result: 121 enterprises that have been established for less than 10 years have successfully gone public, including 87 on the A-share market and 34 on the Hong Kong stock market. More and more young people are closely linking their personal career dreams with the development of future industries here.

Zhang Jichong, a student from the Synthesis Institute of the Shenzhen Institute of Advanced Technology of the Chinese Academy of Sciences: Here, we have the opportunity to be exposed to many cutting-edge research in synthetic biology. In the future, we can either focus on research development or promote applications, contributing to society in a certain way.

Plant "innovation trees" and cultivate "technology forests"

Biological manufacturing holds great promise for the future.

From a bottle of seawater to a straw, from the "cell factory" in the laboratory to a产业集群 with an output value of hundreds of billions, from samples to products and then to industries - at present, a new model of future industrial development with a fully connected ecosystem is gradually taking shape.

In the National Biotechnology Industrial Base in Pingshan, Shenzhen, the research and development team has made use of the complete industrial chain resources to shorten the overall new drug research and development cycle by 20%. On average, each R&D personnel can participate in the development of 10 new drug projects every year.

This is a large-scale scientific facility in the Guangming Science City. Scientists use an automated experimental platform to conduct independent and precise genetic editing and regulation on a large number of samples, significantly enhancing the efficiency of developing synthetic bacterial drugs.

In Weigang Life Science Park, the park has specially designed a research and development environment for biomanufacturing enterprises. It has constructed ultra-high-capacity factories, 24-hour steam systems, and hazardous materials transfer warehouses, among other key industrial supporting facilities, to fully support the enterprises' entire chain development from research and small-scale trials, to large-scale process scaling, and to full-scale production.

Cheng Shaowen, the synthetic biology innovation specialist of the Shenzhen Science and Technology Innovation Bureau: Currently, we have established a complete guarantee system for the entire industry and the entire process of biomanufacturing. There are nearly 400 enterprises related to the biomanufacturing industry. From laying a solid foundation for basic research and building core platforms during the "14th Five-Year Plan" period, to promoting the clusterization and high-end development of the industry during the "15th Five-Year Plan", we are injecting impetus into the future industry.

The data shows that during the "14th Five-Year Plan" period, the investment and financing scale for synthetic biology manufacturing in China has increased to nearly 30 billion yuan per year, and the output of some major products ranks first in the world.

Li Boyang, Director of the Consumer Products Division at the China Academy of Information and Communications Technology: The emerging field of biomanufacturing is accelerating its development. It has achieved parity with developed countries and even leads in some areas. It has also achieved remarkable results in driving the quality improvement and upgrading of traditional industries.

Experts say that currently, China's biomanufacturing industry has entered a crucial development stage. For such a future industry, efforts should be made to accelerate the transformation of innovative achievements from the "death valley" to productive applications.

Li Boyang, Director of the Consumer Goods Division at the China Academy of Information and Communications Technology: During the "14th Five-Year Plan" period, efforts should be made to establish an innovation system for the bio-manufacturing industry, cultivate a number of landmark bio-manufacturing products, and accelerate the development of key emerging fields such as bio-based materials, bio-new energy, biomedicine, and future food.

Li Boyang, Director of the Consumer Goods Division at the China Academy of Information and Communications Technology: During the "14th Five-Year Plan" period, efforts should be made to establish an innovation system for the bio-manufacturing industry, cultivate a number of landmark bio-manufacturing products, and accelerate the development of key emerging fields such as bio-based materials, bio-new energy, biomedicine, and future food.