Recently, the Belgian TripleW company and the Finnish Sulapac company have jointly launched a research project to explore a closed-loop chemical recycling solution for discarded reusable PLA water bottles, in order to replace the traditional industrial composting method.

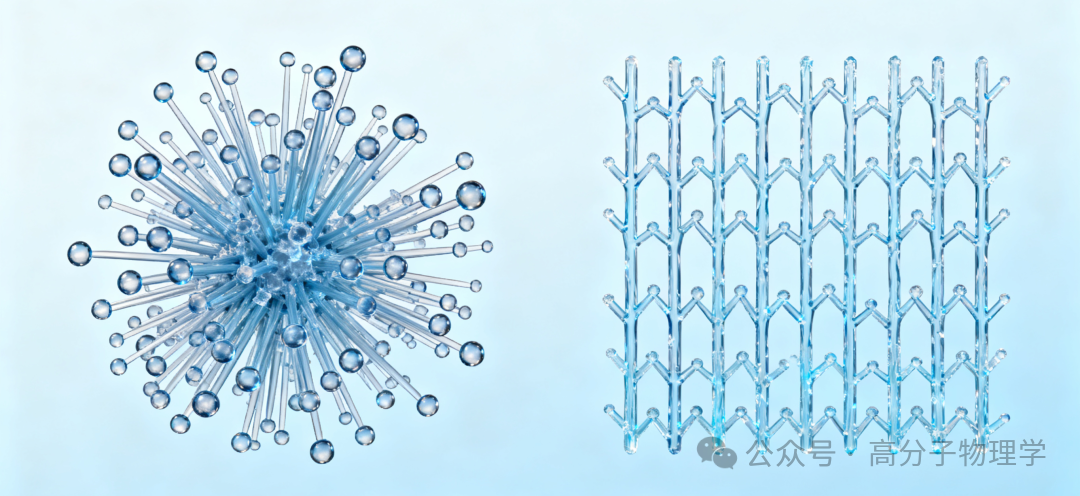

The research subjects of this pilot project are reusable water cups made of the Solid material produced by Sulapac Company. This material is a 100% biobased and biodegradable composite material, with its main components including polylactic acid, cellulose and mineral fillers. The researchers processed these water cups through hydrolysis to extract lactic acid (the monomer of polylactic acid), and the lactic acid can be reused in the production process of polylactic acid.

"This is an important milestone in the implementation of the European bioeconomy strategy," said Tal Shapira, the CEO of the Belgian company TripleW, which specializes in circular bio-industrial business. "In this way, we can eliminate disposable plastic products, enhance the utilization efficiency of bio-based resources, and also help our customers implement the circular development model."

"Nowadays, people no longer have to choose between biodegradable packaging and recyclable packaging," added Heidi Peltola, the chief product officer of Sulapac. "Even reusable products can have both of these properties at the same time."

According to this Finnish manufacturer, the reusable water bottle made of Sulapac's Solid material has significant advantages: it is not only a 100% biobased product, but also has a sturdy texture, a surface that resembles ceramic, and can be washed in a dishwasher; at the same time, it is compatible with mainstream plastic processing techniques such as injection molding, and its formula has been specially optimized to meet the needs of high-frequency usage scenarios such as aviation, cruise ships, and fast food.

In the pilot project, once these PLA water cups reach their service life, they will be uniformly collected, crushed, and then undergo hydrolysis to extract basic components such as lactic acid. Lactic acid has a wide range of applications and can be used in personal care and the pharmaceutical industry. It can also be reconverted into biopolymers through the high-efficiency recycling process "Poly to Poly" developed by the Belgian TripleW company.

Recycling Process Description

1. Restaurant scenario: Daily use of reusable cups (up to 300 uses) → Scrap cups are cleaned and crushed for disposal.

2. Hydrolysis and Purification: The ground materials undergo hydrolysis and purification to convert into lactic acid.

3. Reutilization stage: Lactic acid can be used in the polymerization reaction of polylactic acid, combined to form Sulapac Solid material, and finally reprocessed into cups.