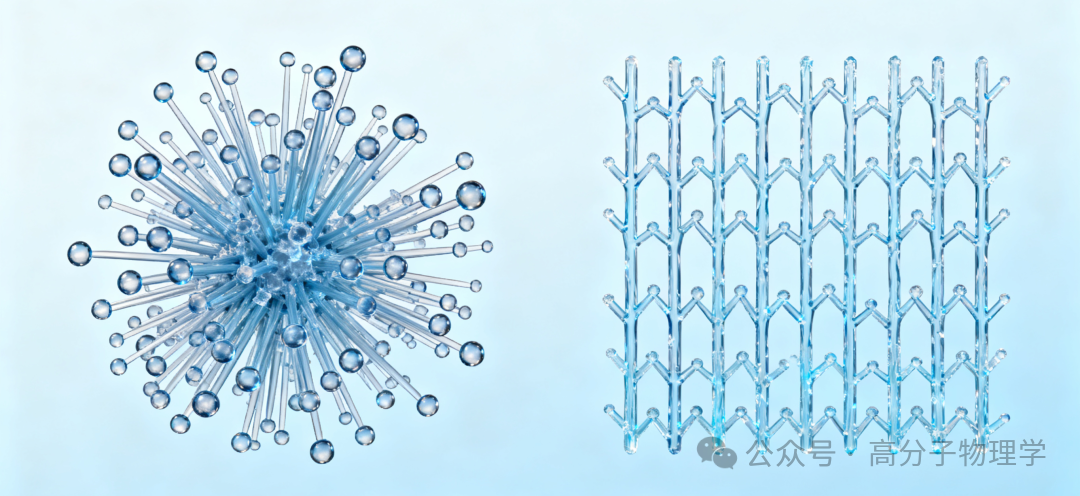

The performance of polylactic acid is fundamentally determined by the "microscopic appearance level" of its crystals. Pure PLA typically forms disordered spherical crystal structures when cooled, with a crystallinity of usually only 30%-40%, resulting in a brittle material with poor heat resistance. The glass transition temperature (Tg) is only 55-65℃, and it easily deforms when exposed to a slight increase in temperature. To solve this problem, the research team has carried out precise control studies on the crystal morphology.

The team from Beijing University of Chemical Technology adopted a combined strategy of "melt blending - annealing control" to introduce organic-modified montmorillonite (OMMT) as a nucleating agent into PLA. Then, the material was subjected to annealing treatment at 90°C. The lamellar structure of OMMT (with a thickness of approximately 1 nm and a diameter of approximately 100 nm) acts like a "seed crystal", guiding the PLA molecular chains to grow along the lamellae. The originally disordered spherical crystals are replaced by regular "branch-like crystals", resulting in a 30% increase in crystallization rate and a 30% improvement in impact strength compared to pure PLA. Polish scholars have also discovered that quercetin, a waste biological filler, can influence the crystal structure like "molecular scissors". While cutting the ester bonds, it unexpectedly promotes the formation of small-sized crystals, indirectly enhancing the degradation compatibility of the material.

Currently, the research still faces some bottlenecks: the crystallization rate of PLA at low temperatures is extremely slow (requiring several days at room temperature), making it difficult to match the industrial production rhythm; and the crystal morphology is extremely sensitive to changes in processing temperature, making batch stability difficult to control. The future trend focuses on the development of "intelligent nucleation systems", using composite nano-clays and bioactive molecules to achieve precise control of crystal morphology and rapid molding.

01 The Optimization Journey from "Corn" to "Products"

01 The Optimization Journey from "Corn" to "Products"

The processing of PLA is a "balance art", requiring the resolution of performance and efficiency issues while maintaining environmental protection attributes. The core processing link begins with the conversion of raw materials: plant starches such as corn and sugar cane are fermented to produce lactic acid, which then undergoes dehydration condensation reactions to form PLA resin, and finally enters the molding stage.

Melt blending modification is currently the mainstream processing technology for enhancing the performance of PLA. Beijing University of Chemical Technology uses a twin-screw extruder for melt blending, uniformly dispersing OMMT into the PLA matrix, and then using a single-screw drawing mechanism to prepare composite material filaments. When the OMMT content is 3%, the tensile strength of the composite material increases by 18%, and the thermal decomposition temperature rises by 25°C, effectively improving the weak properties of pure PLA. In the 3D printing field, researchers have successfully prepared PLA/OMMT composite products with an accuracy of ±0.1mm by optimizing the processing parameters of fused deposition modeling - setting the printing temperature at 210°C, controlling the layer thickness at 0.2mm, and adjusting the filling rate to 80%. This has expanded its application in customized medical stent fields.

However, there are still significant bottlenecks in the processing stage: the processing temperature window of PLA is narrow (only about 20°C), and too high a temperature can easily cause decomposition and produce odors, while too low a temperature will result in insufficient fluidity and lead to forming defects; moreover, the modification processing will increase the cost of PLA by 20%-30%, weakening its market competitiveness. Simultaneously, the "melt blending toughening" process is also developing. By blending with PBAT (polybutylene adipate terephthalate), the impact strength of PLA can be increased by 5 times, but how to balance the toughening effect and degradation rate remains a problem to be solved.

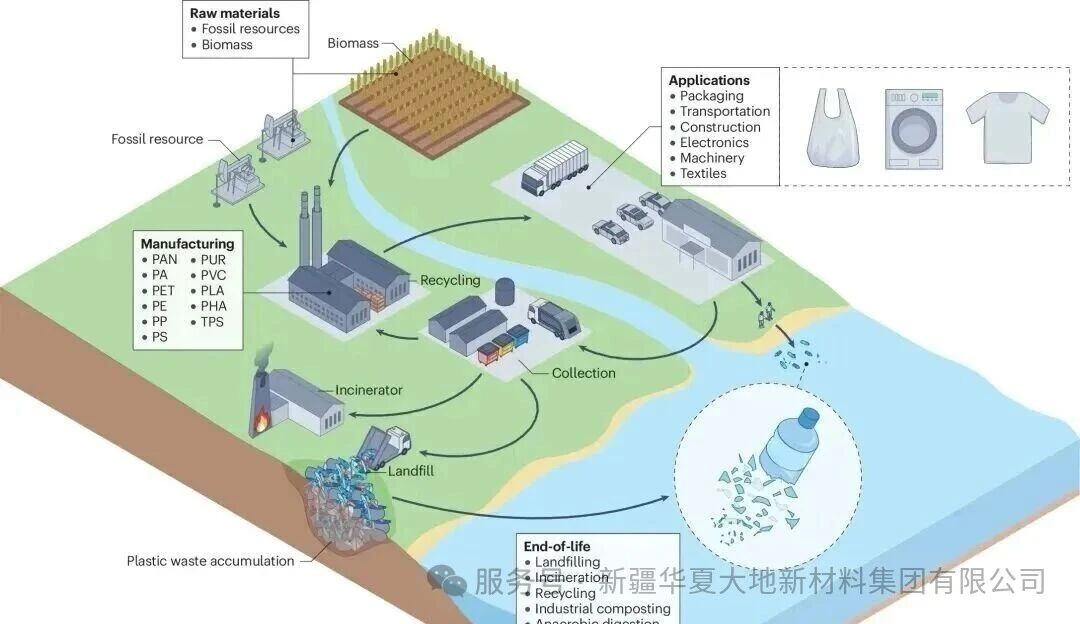

02 The Challenges of Implementation in the Context of Environmental Protection Boom

Due to its biodegradable property, PLA products have penetrated various fields such as packaging, medical care, and 3D printing. In the packaging sector, disposable lunch boxes and shopping bags made of PLA have achieved large-scale application, and the global PLA production capacity reached 2 million tons in 2024. In the medical field, PLA is used in absorbable sutures and fracture fixation nails due to its good biocompatibility. After being implanted in the human body, it can gradually degrade without the need for a second surgery. In the 3D printing sector, PLA filament materials, due to their good molding properties, have become the preferred material for desktop-level printing, occupying approximately 70% of the market share.

However, the market penetration rate of PLA products is still less than 5%. The core problem lies in the application limitations and recycling difficulties. In the packaging scenario, PLA lunch boxes cannot withstand high-temperature food (they deform above 60℃), and when mixed with traditional plastics, they will contaminate the recycling system. In the medical field, high-performance PLA products rely on imports, and there is a gap in degradation rate control accuracy between domestic products and foreign ones. From market feedback, although consumers recognize its environmental value, they have a low acceptance rate for the 30% higher price compared to traditional plastics. And enterprises are constrained by unstable raw material supply and find it difficult to achieve large-scale cost reduction.

03 The "Solution" of the PLA

As a "benchmark material" for degradable polymers, the development process of PLA reflects the common predicament of environmental-friendly materials: the gap between ideal and reality. The OMMT modification research at Beijing University of Chemical Technology and the bio-particle regulation strategy of the Polish team have respectively provided technical paths for the upgrade of PLA from the perspectives of "performance enhancement" and "degradation optimization", proving that through precise material design and processing regulation, PLA is fully capable of breaking through the performance bottleneck.

However, for PLA to truly replace traditional plastics, it needs to overcome "three barriers": technologically, it needs to develop heat-resistant modification formulas and broad-spectrum degradation systems to solve the pain points of "easily deformed at high temperatures" and "slow natural degradation"; industrially, it needs to establish a full-chain system from raw material cultivation to recycling and composting, reducing costs through large-scale production; cognitively, it needs to popularize the correct use and recycling knowledge of PLA to avoid "pseudo environmental protection" applications. In the future, with the deep integration of nanocomposite technology and biological regulation methods, PLA is expected to play a core role in the circular economy and truly achieve the unity of "environmental protection performance" and "practical value".

References:

[1] Wang Hao, Li Juan, Zhang Lei. Preparation of Poly(lactic acid)/Organically Modified Montmorillonite Nanocomposite Filament and Research on Fused Deposition Modeling Process [J]. Polymer Materials Science and Engineering, 2025, 41(10): 32-38.

[2] Nowak A, Kowalczyk D, Wiśniewska G. Regulatory Mechanism of Active Compounds from Waste Bio-fillers on Biodegradation of Poly(lactic acid) Composites [J]. Bioresource Technology, 2025, 428: 126987.

[3] China Plastics Industry Association. 2024 China Biodegradable Plastic Industry Development Report [R]. Beijing: China Plastics Industry Association, 2025.

[4] Zhang H, Liu Y, Chen J. Crystallization Behavior and Mechanical Properties of PLA/OMMT Nanocomposites Prepared by Melt Blending [J]. Journal of Applied Polymer Science, 2024, 141(36): e55892.