On January 16, Amazon announced that it had begun packing and delivering groceries for customers in Spain using bio-based bags made from plant material produced in Europe, including cornstarch and vegetable oil, which can be recycled into new bags. With the support of Amazon material scientists, material experts at Versalis' (Eni) Italian company Novamont have developed the new bag, which is currently undergoing the first trials for Amazon Fresh orders in Valencia. Amazon's biobased packaging is durable, food safe and weatherproof. Due to its safety for food, this new material (Mater-bi) could gradually replace fossil-based plastics used by food retailers and manufacturers. Their biodegradability also means that they do not produce any microplastics. "Our new Amazon Fresh bio-based bag prevents liquid leakage and condensation, protecting customers' orders. At the same time, they have a smaller impact on the planet because they are made with renewable, food-safe plant materials such as cornstarch and vegetable oil, "said Alan Jacobsen, director of Materials and Energy science at Amazon. "Unlike most petroleum-based plastic bags, these materials have the potential to be recycled more efficiently and are able to degrade naturally in a composting environment."

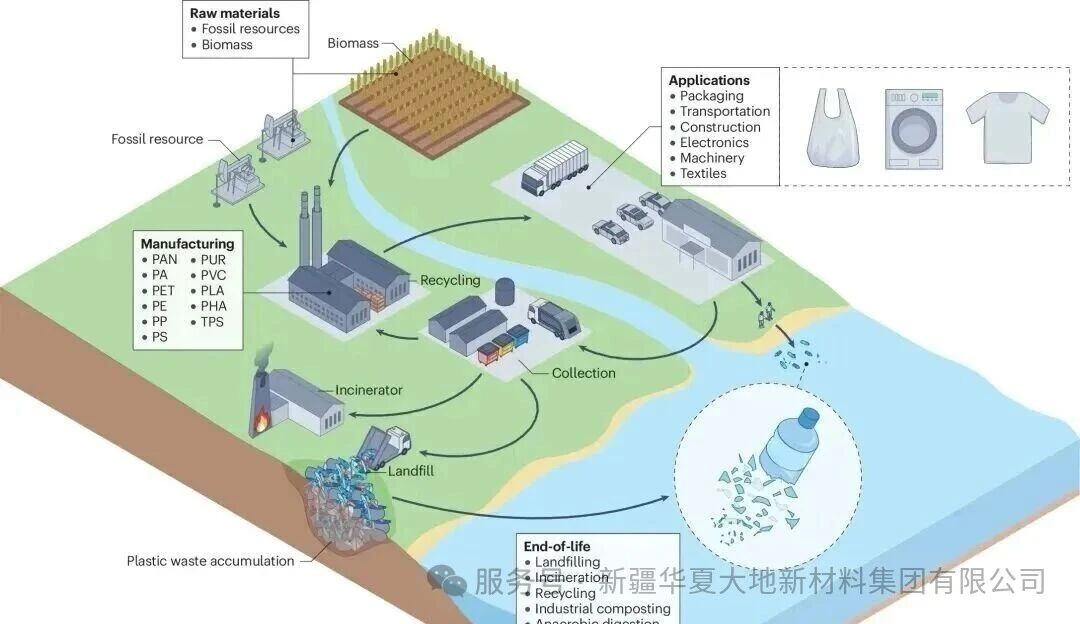

At present, in Valencia, Spain, Amazon Fresh bio-based bags can be reused through mechanical recycling - meaning that a local recycling partner can turn them into plastic pellets, which are then sent to Novamont to make new bags. Working with Amazon is an excellent opportunity to showcase our packaging solutions from our Mater-Bi family of materials that are biodegradable, compostable and derived entirely or partly from biomass, "said Catia Bastioli, CEO of Novamont (Versalis, Eni). "This is a unique opportunity to test the effectiveness of these materials in terms of resource recycling and environmental certification performance with a variety of recycling options." Currently, more than 75% of Amazon customers in Valencia are satisfied with the new bags. Surveys show that they like these bags because they are biodegradable and based on biomaterials, or can be used for other purposes. Amazon will use the results of this pilot to assess whether these new reusable bags can be rolled out to a wider range of applications. In addition to the Amazon Fresh pilot project with Novamont, Amazon's research scientists are also working with the BOTTLE Alliance, led by the U.S. Department of Energy's National Renewable Energy Laboratory (NREL), to develop a new cryogenic recycling process to recover biobased, biodegradable materials. "This process can break down biobased, biodegradable materials into their basic building blocks and repolymerize them into new materials without compromising their material properties," Jacobsen added. "In addition to composting as an end solution for these materials, this new process enables efficient recycling of biodegradable plastics, thereby extending the life of the material and reducing the need for additional raw materials." Using technology developed by NREL and Amazon, the startup EsterCycle aims to take this new process from the lab to the larger scale, allowing biobased, biodegradable plastics to be recycled more widely. The application of a new generation of bio-based and biodegradable materials in packaging, especially in the food and grocery industry, can accelerate the transition to a circular economy and help avoid millions of tons of plastic food and beverage packaging. To improve resource efficiency and cyclicality in the packaging industry, Amazon and Novamont are developing and testing a variety of food-safe bio-based solutions for advanced packaging applications such as yogurt cups, coffee capsules, and fruit and meat containers. This project is co-financed by Circular Biobased Europe.

At present, in Valencia, Spain, Amazon Fresh bio-based bags can be reused through mechanical recycling - meaning that a local recycling partner can turn them into plastic pellets, which are then sent to Novamont to make new bags. Working with Amazon is an excellent opportunity to showcase our packaging solutions from our Mater-Bi family of materials that are biodegradable, compostable and derived entirely or partly from biomass, "said Catia Bastioli, CEO of Novamont (Versalis, Eni). "This is a unique opportunity to test the effectiveness of these materials in terms of resource recycling and environmental certification performance with a variety of recycling options." Currently, more than 75% of Amazon customers in Valencia are satisfied with the new bags. Surveys show that they like these bags because they are biodegradable and based on biomaterials, or can be used for other purposes. Amazon will use the results of this pilot to assess whether these new reusable bags can be rolled out to a wider range of applications. In addition to the Amazon Fresh pilot project with Novamont, Amazon's research scientists are also working with the BOTTLE Alliance, led by the U.S. Department of Energy's National Renewable Energy Laboratory (NREL), to develop a new cryogenic recycling process to recover biobased, biodegradable materials. "This process can break down biobased, biodegradable materials into their basic building blocks and repolymerize them into new materials without compromising their material properties," Jacobsen added. "In addition to composting as an end solution for these materials, this new process enables efficient recycling of biodegradable plastics, thereby extending the life of the material and reducing the need for additional raw materials." Using technology developed by NREL and Amazon, the startup EsterCycle aims to take this new process from the lab to the larger scale, allowing biobased, biodegradable plastics to be recycled more widely. The application of a new generation of bio-based and biodegradable materials in packaging, especially in the food and grocery industry, can accelerate the transition to a circular economy and help avoid millions of tons of plastic food and beverage packaging. To improve resource efficiency and cyclicality in the packaging industry, Amazon and Novamont are developing and testing a variety of food-safe bio-based solutions for advanced packaging applications such as yogurt cups, coffee capsules, and fruit and meat containers. This project is co-financed by Circular Biobased Europe.