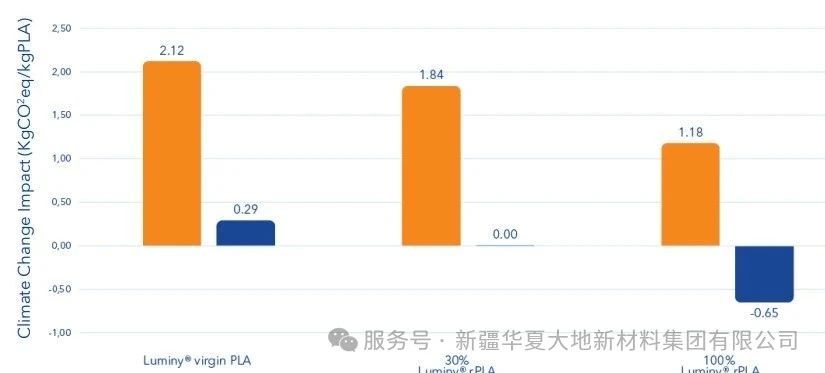

On June 26th, TotalEnergies Corbion released the new results of the PLA life cycle assessment (LCA), highlighting significant progress in the field of low-carbon bioplastics. The latest white paper and related data show that the carbon footprint of Luminy PLA is up to 85% lower than that of traditional plastics. If 30% recycled materials are used, carbon neutrality can be further achieved; if 100% recycled materials are used, a negative carbon footprint can even be achieved. This third-party verified life cycle assessment (LCA) uses the production data of TotalEnergies Corbion's Thai factory in 2024 and is conducted according to the ISO 14040/14044/14067 standards. According to the EU's environmental footprint (EF) method, the environmental impacts of 16 key categories are quantified. The assessment covers both native PLA derived from sugarcane and recycled PLA derived from post-consumer and post-industrial waste.The "from cradle to gate" carbon footprint of native PLA is 0.29 kg CO2-eq/kg, which is 85% lower than that of traditional plastics.

PLA containing 30% recycled components has achieved carbon neutrality, with a carbon footprint of 0.01 kg CO2-eq/kg.

100% recycled PLA has a negative carbon footprint of -0.65 kg CO2-eq/kg.

Thomas Philipon, the CEO of TotalEnergies Corbion, said: "After years of innovation and process optimization, we can now offer polylactic acid products with a lower carbon footprint." This is an important step forward for bioplastics and aligns with our mission to provide sustainable solutions to our customers.

Thomas Philipon, the CEO of TotalEnergies Corbion, said: "After years of innovation and process optimization, we can now offer polylactic acid products with a lower carbon footprint." This is an important step forward for bioplastics and aligns with our mission to provide sustainable solutions to our customers.

Maelenn Ravard, the sustainability manager, added: "This new life cycle assessment demonstrates that polylactic acid can play a key role in building a circular bioeconomy - it is a biobased plastic that can be used for industrial composting and can be recycled." “