PLA is a thermoplastic polyester that is formed by polymerizing lactic acid extracted from renewable resources such as corn and sugar cane. It has the following features:

1. Excellent biodegradability

2. Non-toxic and highly biocompatible

3. Capable of being 3D printed, injection molded, and spun into shapes

However, it is not perfect: it has poor toughness, high brittleness and low heat resistance. These defects severely limit its industrial-scale application.

Therefore, in order to make the PLA stronger, more resilient and more stable, scientists have come up with an endless variety of improvement plans ranging from molecular structure to composite materials.

Blending modification

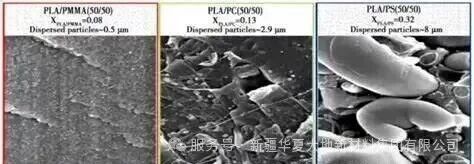

The brittleness and low toughness of polylactic acid (PLA) itself are the main drawbacks that hinder its wide application. Blending modification is one of the most common solutions to this problem. By mixing PLA with other high-molecular materials that have flexibility or extensibility, the complementary properties of the materials can be achieved.

Case: Improving ductility through blending PLA and PCL

The research group led by Professor Li Jianjun from Beijing University of Chemical Technology used the melt blending process to introduce different proportions of PCL into PLA, and found:

The elongation at break of the PLA/PCL (80/20) blend has increased from 6% of the original PLA to 215%.

2. The tensile strength has slightly decreased, but the overall performance is excellent.

3. The SEM analysis shows that PCL is uniformly dispersed in PLA, forming a distinct "island-like structure".

4. Thermogravimetric analysis (TGA) indicates that the thermal stability of the composite material has slightly improved.

This study clearly indicates that the addition of PCL not only maintains the environmentally degradable property of PLA but also significantly enhances its processing toughness and ductility, making it suitable for applications in packaging films, agricultural films, 3D printing, and other fields.

As the exploration continues to deepen, more and more blending objects have been meaningfully discovered. For example: blending with PBAT (alkyl-aromatic copolyester) can increase flexibility and improve low-temperature performance; blending with TPS (thermoplastic starch) can reduce the cost of PLA, but it requires enhancing interfacial compatibility; PEG (polyethylene glycol) can be used as a plasticizer to improve processing performance and flexibility.

Nano-enhanced modification

While blending modification focuses on flexibility, nano-reinforcement modification aims to enhance the strength, thermal stability and functionality of PLA, making it closer to the performance of "engineering plastics".

Nanofillers typically include inorganic particles (such as SiO₂, TiO₂), layered materials (such as montmorillonite), or carbon-based materials (such as graphene, carbon nanotubes). These materials form strong interfacial interactions with the PLA matrix at the micro-nano scale, effectively enhancing the performance of the material.

Case: PLA/nano-SiO₂ Composite Material

Performance Optimization

The research team from the School of Materials Science and Engineering of Sun Yat-sen University adopted the in-situ polymerization method to uniformly disperse surface-modified nano-SiO₂ in PLA at a mass fraction of 1.5%.

This study shows that when 1.5 wt% of surface-modified nano-SiO₂ is introduced into the PLA matrix, the comprehensive performance of the material has been significantly improved:

The heat distortion temperature (HDT) has increased from the original 58.3℃ of PLA to 74.1℃, demonstrating a greater heat resistance and facilitating the expansion of its application range in high-temperature environments.

2. The tensile strength increased from 54 MPa to 63 MPa, indicating that the mechanical properties of the material have improved and the structure has become more robust.

3. The oxygen permeability decreased from 480 cc/m²·day to 260 cc/m²·day, significantly improving the gas barrier performance. This is beneficial for extending the shelf life of food or medicine in packaging materials.

4. In terms of antibacterial performance, the original PLA has almost no inhibitory effect on Staphylococcus aureus, while the antibacterial rate of the composite material exceeds 90%. It exhibits excellent antibacterial activity and is suitable for scenarios with high hygiene requirements such as healthcare.

Trend Development

As the concept of green manufacturing gains widespread acceptance, the research on PLA shows the following trends:

1. Function integration: Integrated functions such as conductivity, self-repairing, and flame retardancy.

2. Green modification: Natural fibers and bio-based additives gradually replace petrochemical additives

With the continuous advancement of the "carbon neutrality strategy" and the deep-rooted concept of green manufacturing, polylactic acid (PLA) is no longer merely "degradable", but is evolving towards higher levels of high-performance, multi-functionality and intelligence:

1. Functional Integration: From "usable" to "user-friendly"

Although traditional PLA materials are environmentally friendly, they have limited performance and are unable to meet the requirements of complex applications. Researchers are currently working on endowing them with more functions.

By incorporating carbon nanotubes, graphene, etc., various functions such as intelligent packaging and electric heating films can be achieved.

Introduce phosphorus-based flame retardants and bio-based modified additives to enhance their safety in the fields of electronics and electrical appliances;

By using microcapsules or dynamic covalent bonds for design, the material can achieve self-healing after micro-damage, thereby extending its service life.

The functional integration makes PLA not only "green" but also "intelligent".

2. Green modification: Moving from "degradable" to "fully biobased"

During the modification process of PLA, most of the traditional additives are derived from petrochemical resources and are difficult to degrade or have certain toxicity. Therefore, the research team is actively exploring green alternative approaches:

Utilizing natural fibers to enhance the strength and degradation synergy of PLA;

Introduce biobased plasticizers and additives to replace traditional chemical additives;

Develop a fully biobased composite system, striving for a "zero petrochemical" approach throughout the entire process from source to degradation.

Not only does it degrade materials, but it also provides a "green full-chain solution".

3. Intelligent Manufacturing Integration: Making PLA More Suitable for "Future Factories"

The excellent fluidity and moldability of PLA make it naturally suitable for integration with advanced manufacturing technologies, especially in 3D printing, micro injection molding, and moldless processing, presenting broad prospects:

3D printed PLA filament has become one of the most widely used materials in FDM printing, suitable for the manufacturing of customized components in fields such as education, healthcare, and construction.

By integrating digital twin technology with parametric design software, it is possible to achieve "real-time optimization during printing" for personalized functional PLA products.

The intelligent monitoring system can track the printing parameters and forming quality in real time, enabling green and controllable production processes.

PLA is no longer just a material; it has become a part of the intelligent manufacturing chain.

Intelligent manufacturing integration: Combined with cutting-edge technologies such as 3D printing, to create a new ecological system of "personalized + environmentally friendly" products

Challenge

Although the research achievements of PLA modification have been abundant in recent years, there are still many practical difficulties in moving from the laboratory to large-scale industrial application:

The evaluation of degradability lacks systematic standards.

Although many modified PLA products have significantly improved their performance, their degradation behavior has become complex or even unstable. Currently, the degradation evaluation systems under different environments (such as composting, soil, and seawater) are not unified, which affects their environmental certification and promotion.

2. Insufficient interface compatibility and industrial processing adaptability

After blending or nano-modification, problems such as poor compatibility between components and uneven dispersion often occur, resulting in fluctuations in product performance and making it difficult to achieve stable mass production.

Meanwhile, the industrial-scale production equipment has limited adaptability to PLA and further optimization of the processing window and rheological control is required.

3. The cost is still higher than that of traditional plastics, and the pressure from commercial competition is significant.

At present, the raw material costs and production processes of PLA are still relatively high. Especially when the prices of petrochemical plastics are low, PLA has difficulty gaining a price advantage in the commodity market. Therefore, it urgently needs policy support and technological breakthroughs to reduce the unit cost.

Summary

Polylactic acid is merely a starting point towards the era of green materials. What it reveals is the broad direction of future materials science, which integrates ecology, safety and intelligence. I believe that with the deepening of research, the advancement of technology and market incentives, PLA will truly demonstrate its vitality in more fields.

References

[1] Ye, X., Wang, Y., & Zhang, L. (2023). Poly(lactic acid)/poly(ε-caprolactone) blends: The influence of compatibilizer on mechanical properties. Frontiers in Materials, 10, 1377340.

[2]Chen, Y., Zhang, X., Shao, W., et al. (2020). Enhanced barrier and antibacterial properties of PLA nanocomposites by incorporating surface-modified nano-SiO₂. Journal of Applied Polymer Science, 137(34), 48951.

[3] Chen Yizhong, Gong Degun, Fu Xuejun, et al. Effects of Additives and PLA on the Mechanical and Release Properties of PBAT Blends [J/OL]. Modern Plastic Processing Applications, 1-5 [2025-05-27]. https://doi.org/10.19690/j.issn1004-3055.20240119.

[4] Zhang Yuli, Chen Yingzhe, Lei Yashuo, et al. Progress in the reinforcement and modification of polylactic acid [J]. Plastics, 2025, 54(01): 176-180.