Article background

Polylactic acid (PLA) is a polyester polymer with lactic acid as a repeating unit, which has good biodegradability and can be degraded into water and carbon dioxide when used and discarded, without polluting the environment. As a biodegradable and environmentally friendly polymer, polylactic acid is widely used in contemporary society, such as in the field of fiber materials can replace some traditional polymers. However, it has limited stability and low melting point, which limits its use in heat-resistant and durable application scenarios.

Article overview

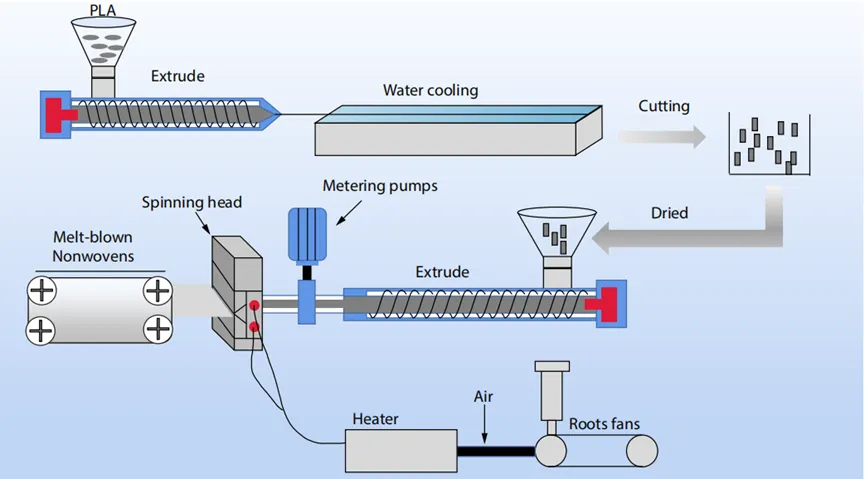

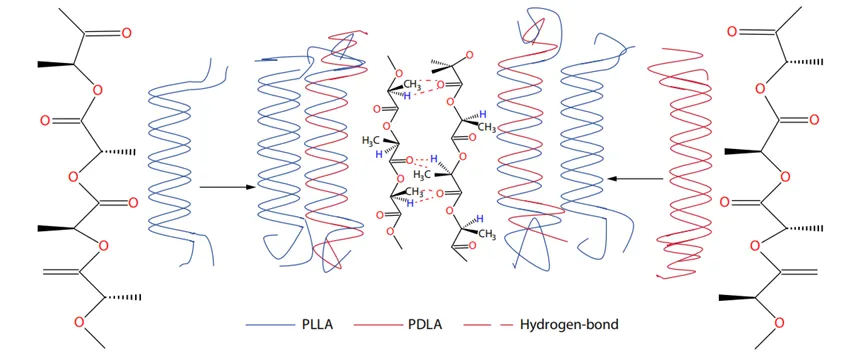

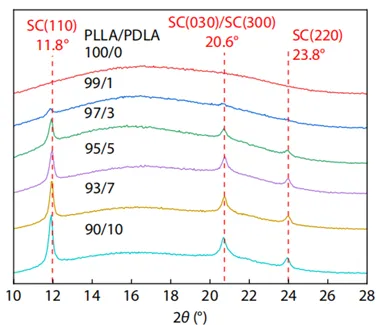

Based on the above background, recently, the research group of Zhang Huiliang, a researcher at Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, used the melt blending method of left-handed polylactic acid (PLLA) and right-handed polylactic acid (PDLA) to prepare the stereo-composite crystal modified polylactic acid melt-blow nonwovens (Figure 1). The stability of polylactic acid melt-blown nonwovens was improved by the formation of composite crystals (FIG. 2). The structure, thermal properties, thermal stability, biodegradability and crystal morphology of the polymer were studied in detail. With the increase of PDLA content, more stereic composite crystals were formed, and the WAXD diffraction peak of stereic composite crystals gradually increased (FIG. 3). FIG. 1 melt-blown nonwovens manufacturing process.

FIG. 1 melt-blown nonwovens manufacturing process. FIG. 2 Schematic diagram of formation of stereo-composite crystals.

FIG. 2 Schematic diagram of formation of stereo-composite crystals. Figure 3. WAXD diffraction pattern of melt-blown nonwovens.

Figure 3. WAXD diffraction pattern of melt-blown nonwovens.

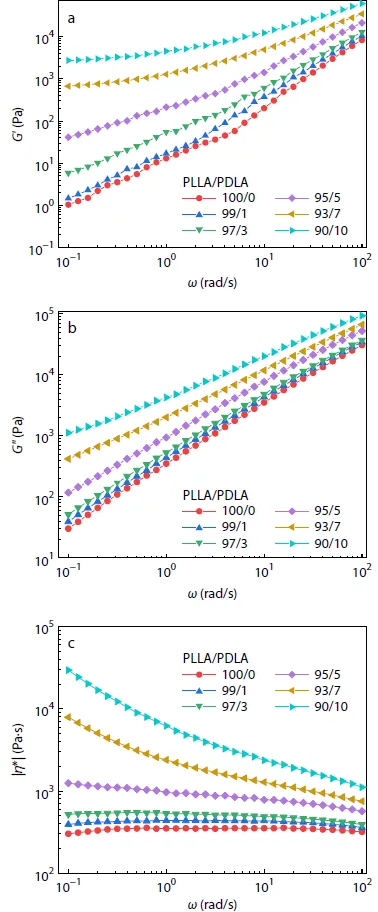

The energy storage modulus (G'), loss modulus (G ") and complex viscosity (|η*|) of PLLA/PDLA blend increased with the increase of the content of the composite crystals, as shown in Figure 4. In terms of rheology, when the content of PDLA is 0 wt%~3 wt%, the viscosity of the system is almost unchanged due to the small content of the stereo-composite crystal, and the system exhibits Newtonian fluid behavior. Beyond 3 wt%, non-Newtonian behavior becomes more pronounced. Figure 4 (a) of PLLA/PDLA blend energy storage modulus (G '), (b) loss modulus (G ') and (c) a plural viscosity (| | eta *).

Figure 4 (a) of PLLA/PDLA blend energy storage modulus (G '), (b) loss modulus (G ') and (c) a plural viscosity (| | eta *).

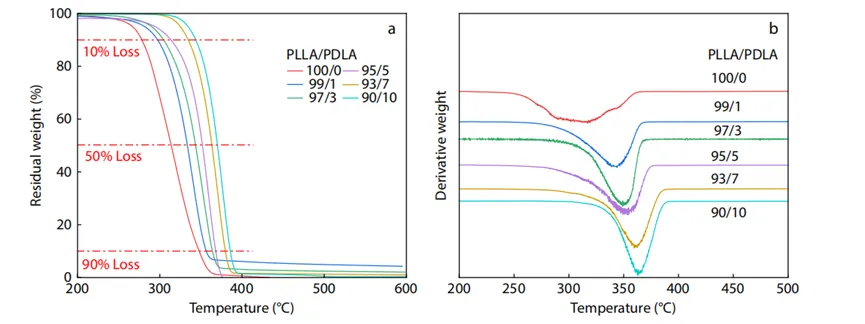

The thermogravimetric analysis (FIG. 5) results show that the thermal stability of PLLA/PDLA melt-blown nonwovens is significantly enhanced compared with pure PLLA melt-blown nonwovens. When the PDLA content reached 10 wt%, the 10% weight loss temperature (T10%) increased from 277.5 ℃ to 342.4 ℃, and the maximum decomposition rate temperature increased from 324.7 ℃ to 376.8 ℃. This is due to the formation of stereo-composite crystals, and enhanced molecular interaction, improve the thermal stability of the material. FIG. 5 Thermogravimetric curve of polylactic acid melt-blown nonwovens.

FIG. 5 Thermogravimetric curve of polylactic acid melt-blown nonwovens.

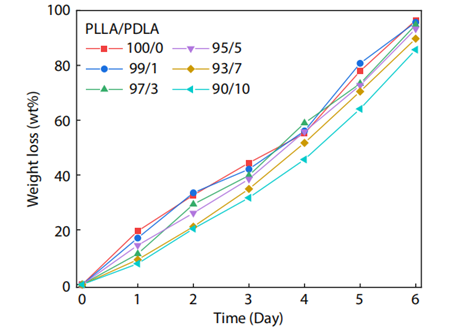

Biodegradability As shown in Figure 6, the weight loss rate of PLLA/PDLA melt-blown nonwovens decreased with the increase of PDLA content, but the overall degradation rate remained at a high level. Compared with pure PLLA, stereo-composite crystals have stronger resistance to protease K. Protease K preferently degrades amorphous regions during enzymolysis, while stable stereo-composite crystals as crystal skeleton improve the resistance to enzymolysis. Figure 6. Weight loss curve of enzymatic degradation of polylactic acid melt-blown nonwovens over time.

Figure 6. Weight loss curve of enzymatic degradation of polylactic acid melt-blown nonwovens over time.

Conclusion of the article

This study provides an effective strategy for obtaining and large-scale preparing high-performance polylactic acid melt-blown nonwovens. The prepared environment-friendly polylactic acid melt-blown nonwovens have excellent performance in thermal stability and resistance to degradation, which is expected to expand the application of PLA materials in packaging, filtration, medical treatment and other fields. In the future, the research team will further explore ways to optimize material properties, promote the wide application of PLA materials in more industries, and help sustainable development.