On August 12th, a groundbreaking study was published in the journal ACS Sustainable Chemistry & Engineering. The research team demonstrated for the first time that under normal pressure, microwave-driven catalysis can convert lignin into a phenolic mixture and successfully apply it to soy protein adhesives. The research was jointly completed by researchers from West Virginia University and North Carolina State University, opening up a new path for the high-value utilization of lignin.

Lignin is a waste product generated during the processing of biomass and has traditionally been incinerated to supplement the energy supply of factories. However, lignin has the potential to be converted into high-value chemicals. Specifically, lignin-derived phenolic mixtures, as components of soy protein adhesives, show great application prospects. But traditional methods require high-pressure conditions and specific hydrogen sources, increasing production costs and complexity.

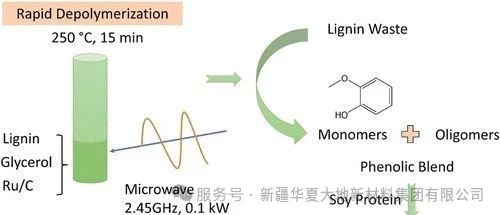

This study innovatively adopted atmospheric pressure microwave-driven catalytic technology, using glycerol as the solvent, to achieve efficient depolymerization of lignin. The process was carried out at 250°C and only required 15 minutes to reach a lignin conversion rate of approximately 89%. In contrast, traditional high-pressure liquefaction processes often take several hours or even longer, which reduces equipment requirements and production costs.

Technical Details:

Solvent selection: Glycerol is chosen as the solvent due to its high boiling point (290°C) and renewability, allowing the reaction to proceed at high temperatures without the need for pressure. Additionally, glycerol is a biodegradable, non-toxic hydrogen donor solvent.

Catalyst application: In the research, the Ru/C catalyst was used. Its 10% ruthenium loading effectively promoted the depolymerization of lignin. The recyclability of the catalyst further enhanced the sustainability of the process.

Preparation of phenolic mixture: Through microwave heating, lignin is depolymerized in glycerol solvent, and the resulting phenolic mixture is retained in glycerol. Subsequently, it is separated by centrifugation. This mixture mainly consists of monomers and oligomers, and contains important phenolic compounds such as eugenol and 4-ethyl eugenol.

The research team mixed the phenolic mixture (containing monomers and oligomers) obtained through the transformation with soybean protein solution to create a soybean protein-based adhesive. This adhesive performed exceptionally well in the single lap shear strength test. The research showed that when the solid content of the adhesive was 68%, its bonding strength reached 2.28 MPa, which not only exceeded the bonding strength of a commercial soybean protein adhesive with a solid content of 34 wt% (2.02 MPa), but also met the strength requirement of at least 1.0 MPa for commercial applications. This discovery indicates that the phenolic mixture can partially replace soybean protein while not reducing the bonding performance of the adhesive.

This research not only provides a new method for the high-value utilization of lignin waste, but also reduces the reliance on soy protein, which helps to lower the production cost of soy protein adhesives. Moreover, the atmospheric pressure microwave-driven catalytic technology has the advantages of high efficiency, environmental friendliness and scalability, and opens up a new path for the sustainable utilization of biomass resources.