In today's era of escalating plastic pollution, the shadow of white waste has spread over the oceans, the soil, and even the air. Traditional plastics are made from petroleum and take hundreds of years to decompose. However, the emergence of polylactic acid (PLA) has brought a refreshing trend to the field of environmental-friendly materials. This new type of material, known as "degradable green plastic", is quietly changing the relationship between humans and plastics with its unique ecological advantages.

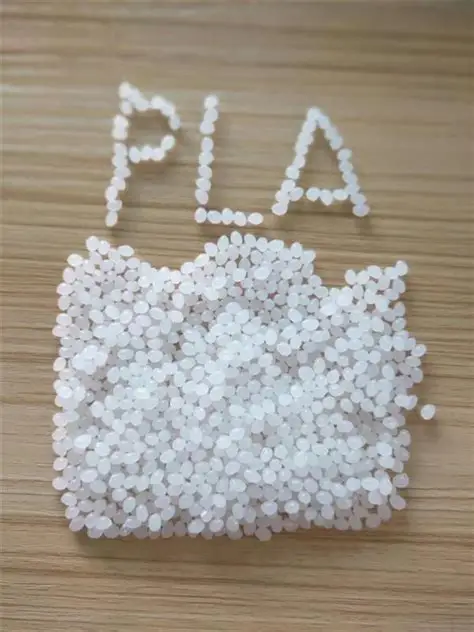

The "green gene" of polylactic acid stems from its natural raw material composition. It is made from starch extracted from renewable plant resources such as corn and sugarcane, which is then fermented into lactic acid and chemically synthesized to form a polymer material. This process not only eliminates reliance on petroleum, but also creates a "closed-loop cycle" of "plants absorbing carbon dioxide - starch converting into polylactic acid - returning to nature after disposal", which is different from the traditional plastic extraction from underground and non-renewable path. Polylactic acid is marked with a low-carbon and environmentally friendly imprint from the very beginning.

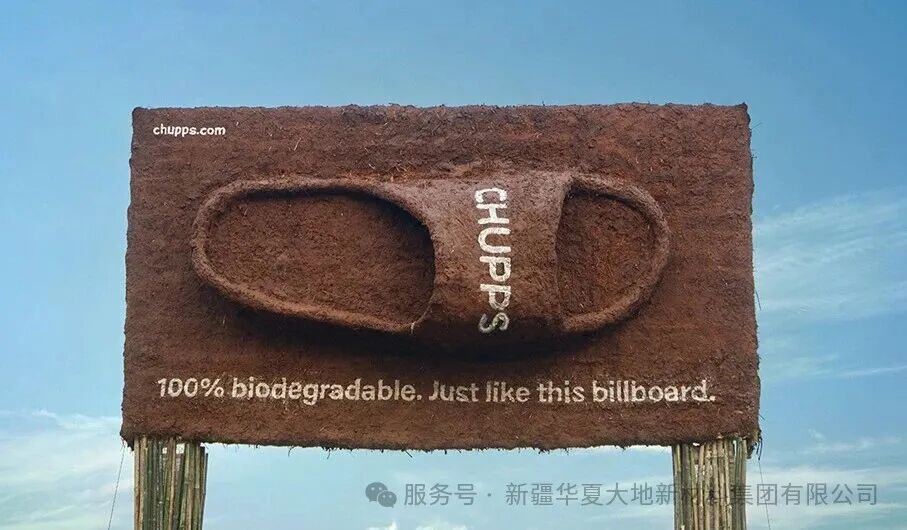

What truly sets polylactic acid apart is its core characteristic of "decomposability". Under industrial composting conditions, polylactic acid products can completely break down into carbon dioxide and water within just 180 days, returning to the natural cycle. Even in the natural environment, its degradation rate is much faster than that of traditional plastics. This characteristic stems from the ester bonds in its molecular structure. Under the action of microorganisms or enzymes, the ester bonds break, and the material gradually disintegrates into small molecules, which are eventually fully absorbed by the ecosystem. In contrast, the carbon chains of ordinary plastics are stable and difficult to be decomposed by nature. They can only break down into microplastics, causing long-term harm to the environment.

The environmental value of polylactic acid is also reflected in its low carbon footprint throughout its entire life cycle. From raw material cultivation to production and processing, its carbon emissions are more than 60% lower than those of traditional plastics. After being discarded, if it undergoes composting treatment, it can avoid the emission of toxic gases from incineration. What's even more surprising is that its physical properties are close to those of traditional plastics, and it can be made into packaging films, tableware, fibers, and even medical implants. Its application scenarios cover daily life and high-end manufacturing. This "environmentally friendly without sacrificing functionality and aesthetics" characteristic enables polylactic acid to reduce pollution without sacrificing the functionality and aesthetics of the product.

From the farmland to the dining table, from the factory to nature, polylactic acid has redefined the life cycle of plastics through technology. It is not only a breakthrough in materials science, but also an attempt for humans to reconcile with nature.