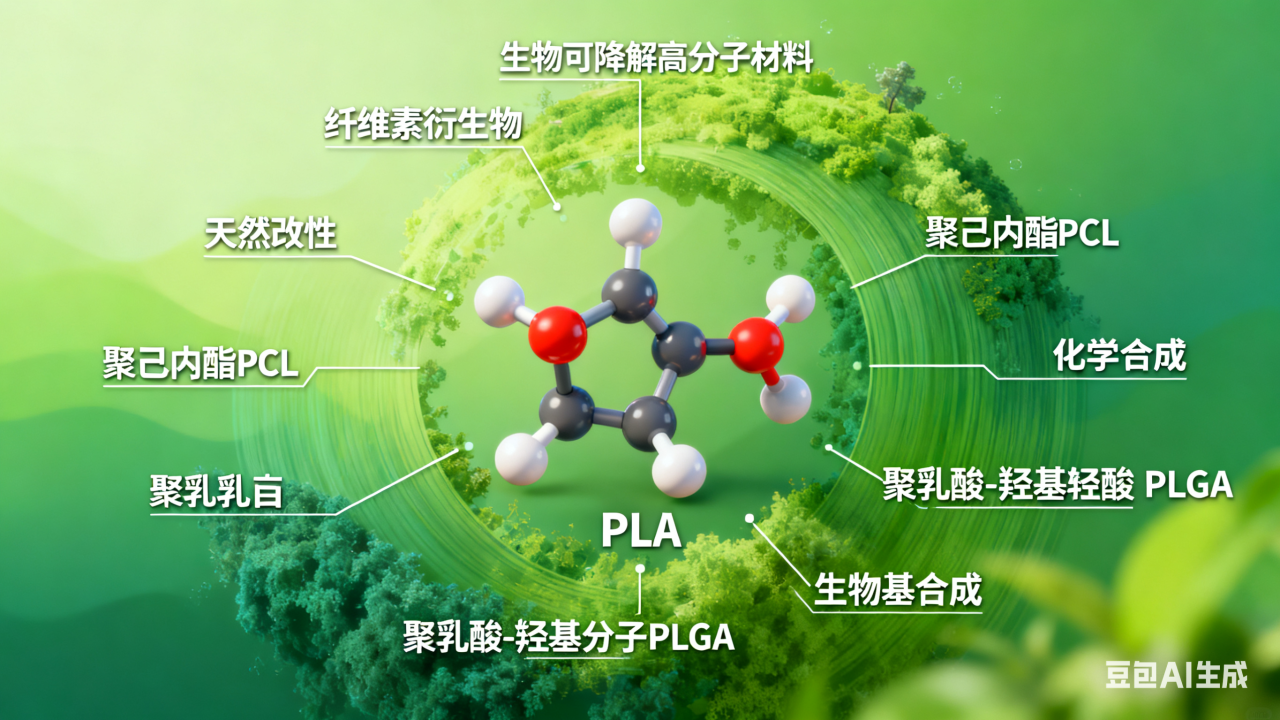

The types of microsphere materials are diverse. This article will focus on representative synthetic polymer materials. Polylactic acid (PLA), as a typical synthetic polymer material, has received extensive attention in multiple fields in recent years, providing an important example for microsphere materials.

01 Definition of Polylactic Acid

Polylactic acid (PLA) is a biodegradable polymer material synthesized from biomass raw materials through microbial fermentation. Its main raw materials include various biomass resources such as corn, cassava, sugar beet, sugarcane, and straw cellulose. The biomass resources are converted into small molecules of lactic acid through microbial fermentation, and then polymerized to form polylactic acid.

As a fatty acid-based polyester, polylactic acid has a wide range of raw material sources. Taking China as an example, the annual output of agricultural straw is approximately 800 million tons, which provides a rich raw material foundation for the production of polylactic acid. Polylactic acid has excellent biocompatibility, being able to be compatible with biological tissues or cells without causing immune reactions or other adverse reactions; at the same time, it has excellent biodegradability, gradually decomposing into carbon dioxide and water in the natural environment, and being harmless to the environment.

02 Preparation of Poly(lactic acid) Microspheres

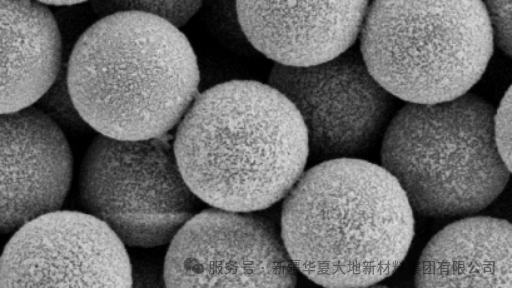

The preparation methods of polylactic acid microspheres are diverse. Common ones include the emulsification solvent evaporation method and the membrane emulsification method, etc.

Emulsifying solvent evaporation method

This is one of the most commonly used preparation methods, which can be divided into single emulsion method and double emulsion method. Poly(lactic acid) is dissolved in an organic solvent, and then dispersed into the aqueous phase through mechanical stirring or ultrasonic emulsification to form an emulsion. Subsequently, the organic solvent is volatilized to solidify the poly(lactic acid) and form poly(lactic acid) microspheres. This method is easy to operate and suitable for small-scale laboratory preparation, but it is difficult to control the particle size distribution.

Membrane emulsification method

This method is an emerging technology developed based on the emulsification solvent evaporation method. Usually, the organic solution containing PLA and the aqueous phase are placed on both sides of a microporous membrane respectively. Through the microporous membrane, uniformly sized emulsions are formed, and then the solvent is evaporated to form poly(lactic acid) microspheres. The significant advantage of this method lies in its ability to produce poly(lactic acid) microspheres with uniform particle size and excellent monodispersity, which is suitable for applications with high requirements for the quality of poly(lactic acid) microspheres. However, the equipment cost is relatively high and the operation is relatively complex.

In practical applications, it is necessary to comprehensively consider the application requirements of polylactic acid microspheres, the quality control requirements, and the cost, etc., and select an appropriate preparation method to achieve the best results.

03 Applications of Poly(lactic acid) Microspheres

Polylactic acid microspheres possess excellent biocompatibility, biodegradability and good physical and chemical stability. As consumers' demand for natural, environmentally friendly and efficient cosmetics continues to increase, polylactic acid microspheres, as a green and sustainable material, have gradually become a popular choice in cosmetic research and development.

Moisturizing and Repairing:

Lactic acid is a natural moisturizing factor for the skin. It can effectively promote the water retention of the stratum corneum and enhance the skin's moisturizing ability. Some high-end skin care products add polylactic acid microspheres to address issues such as dry and rough skin, making the skin texture softer and smoother.

Anti-aging:

Polylactic acid microspheres have outstanding applications in this field, especially in products such as anti-wrinkle injections. As the microspheres gradually degrade, the released lactic acid can promote the metabolism of skin cells, stimulate the regeneration of collagen, help reduce the formation of wrinkles, enhance skin elasticity and firmness, and achieve anti-aging effects.

Sunscreen carrier:

Traditional sunscreens often encounter problems such as poor stability and easy loss. Poly(lactic acid) microspheres can serve as an efficient carrier, encapsulating the sunscreen agent within their stable structure, thereby enhancing the stability of the sunscreen agent. At the same time, it can reduce the direct contact between the sunscreen agent and the skin, minimizing irritation. Its sustained-release property can also prolong the effect time of the sunscreen agent, providing a more lasting protective effect.

Summary

This article introduces the material characteristics, main preparation methods, and application in the cosmetics field of synthetic polymer material - polylactic acid microspheres. The preparation techniques for polylactic acid microspheres are diverse. The emulsification solvent evaporation method and membrane emulsification method are two commonly used methods, each with its own characteristics and applicable scenarios. When choosing, factors such as application requirements, quality standards, and cost need to be comprehensively considered.

As an excellent and environmentally friendly green material, polylactic acid microspheres have broad prospects for development in the fields of cosmetics and biomedicine, and are expected to play a more significant role in future research and development.