On September 9th, Sulzhu collaborated with the Israeli pioneer in circular chemistry, TripleW, and launched the world's first PLA (polylactic acid) bioplastic that is entirely made from food waste.

Among them, TripleW is responsible for the value-added processing of food waste logistics, while Sulzer uses its technology to convert lactic acid into PLA bioplastics on a large scale, helping the project move from the innovative pilot stage to full-scale industrial production. With the support of the CIRCLE alliance, this global breakthrough marks an important step forward in the sustainable manufacturing of the circular economy.

The collaborative achievement of Sulzer and TripleW: A type of polylactic acid (PLA) entirely made from food waste.

The collaborative achievement of Sulzer and TripleW: A type of polylactic acid (PLA) entirely made from food waste.

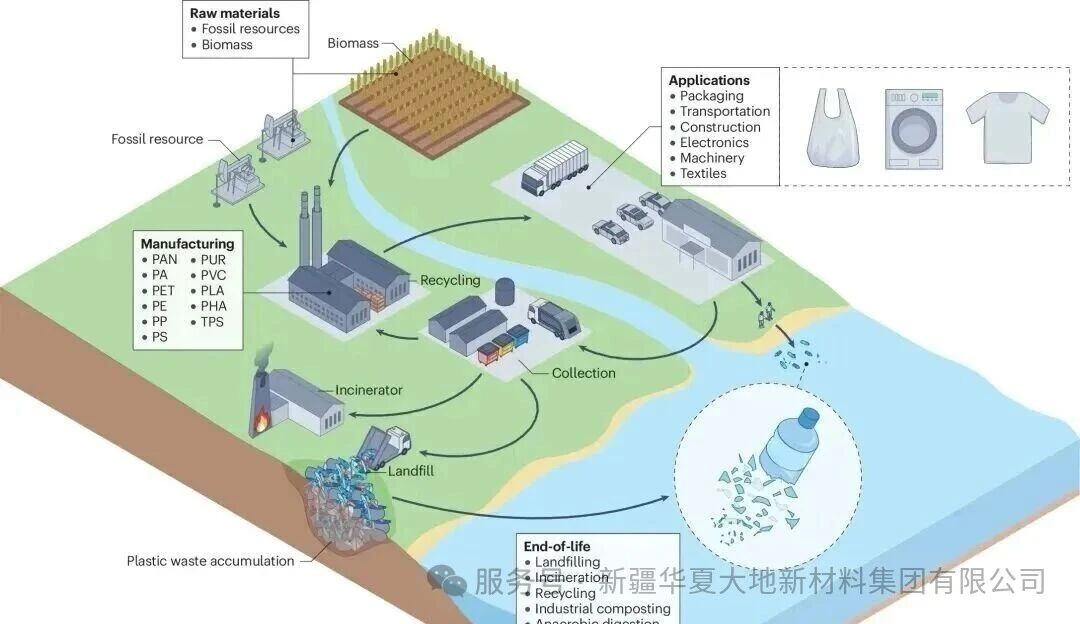

PLA bioplastics have been widely used in various fields. However, now they can be completely made from PLA derived from food waste, thereby reducing reliance on fossil raw materials and helping to eliminate food waste. The new PLA is produced from by-products of the food industry (including bakery waste and expired goods), turning these underutilized wastes into high-performance bioplastics.

"Supporting TripleW's verification and expansion of converting the lactic acid produced from food waste into PLA is a unique milestone in the history of PLA development. We believe that this industry will benefit greatly from utilizing various biopolymer raw materials. We are looking forward to implementing this process on a larger scale," said Virginie Belliere-Baca, the Global Head of Technology and Innovation at SUEZ.

Tal Shapira, the CEO of TripleW, said: "This release is a crucial step towards increasing the adoption of bioplastics in consumer brand products. TripleW is very pleased to be able to provide the materials needed for the transition to a true circular economy. "We are very proud to collaborate with Sulzer and to showcase the development of highly scalable circular materials with an excellent partner."

The demonstration facility of TripleW in the next-generation development zone of the Port of Antwerp

The demonstration facility of TripleW in the next-generation development zone of the Port of Antwerp

The CIRCLE alliance is funded by the European Circular Bio-based Joint Undertaking (CBE JU), aiming to establish a fully integrated value chain for bio-based materials derived from food waste by bringing together industry partners. Thanks to Sulzer's process expertise, which has contributed to the technological and commercial success, the revolutionary PLA bioplastic derived from food waste can now be effectively used by the consortium partners and global brands as an alternative to fossil materials in textiles, packaging, and consumer goods.

The demonstration factory of TripleW, located in the Next Gen District of Antwerp Port in Belgium, has officially started operation. This factory can process 10 tons of waste per day and produce lactic acid.

TripleW is not the only company that uses food waste to produce lactic acid. "But we are the first company to produce lactic acid on a large scale," said Shapira, the co-founder and CEO of TripleW. "We also plan to build a commercial-scale lactic acid production plant on an adjacent site: increasing the daily processing capacity from 10 tons to 300 tons."

So far, the demonstration project has received 10 million euros in investment. The commercial production will require 70 million euros. To achieve this goal, TripleW is seeking support from Belgian companies.

The TripleW team visited the newly established innovation technology center in Switzerland (InTecH personnel list: )

Tal Shapira: Chief Executive Officer of TripleW

Virginie Belliere-Baca: Head of Global Technology and Innovation at Sulzweiler

Maarten Campman: President of TripleW Production

Simonetta Rima: Head of Global Polymer and Recycling Business at Sulzer