Polylactic acid (PLA), as a completely biodegradable polymer material, demonstrates great application potential in the field of bone repair due to its excellent biocompatibility and absorbability. It can effectively avoid the problem of the need for a second surgery to remove traditional metal implants. However, PLA itself has some drawbacks such as insufficient mechanical strength, high brittleness, acidic degradation products, and lack of biological activity, which severely limit its practical application in the repair of bone defects. To overcome these limitations, researchers have widely adopted the strategy of fiber reinforcement in recent years. By introducing various fiber materials into the PLA matrix, their mechanical properties and biological functions have been significantly improved.

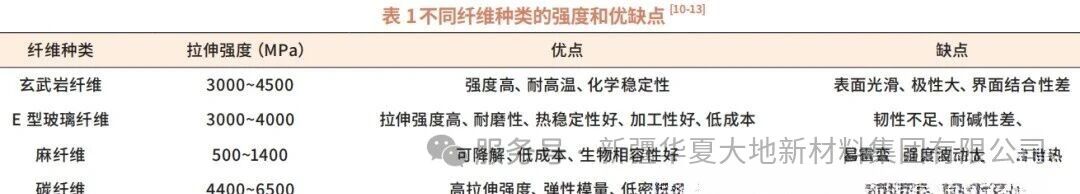

There are a wide variety of fiber types that can be used to enhance PLA, mainly divided into two categories: natural fibers and synthetic fibers.

Natural fibers include volcanic rock fibers and serpentine from mineral sources, jute, bamboo, coconut shell fibers from plant sources, as well as silk and collagen fibers from animal sources. They generally possess excellent biodegradability and environmental friendliness. However, due to their high strength, high water absorption, and poor thermal stability, they often require treatment methods such as alkali treatment and coupling agent modification to improve their interfacial compatibility with PLA.

Artificial fibers include glass fibers, carbon fibers, metal fibers (such as stainless steel and magnesium alloy wires), bioactive ceramic fibers (such as hydroxyapatite and bio-glass fibers), and synthetic polymer fibers (such as PGA, PVA, PVDF, aramid, etc.). These fibers typically have higher strength, modulus, and controllable degradation rates. When combined with PLA, they exhibit more significant enhancement efficiency and structural designability.

The introduction of fibers significantly enhances the tensile strength, bending modulus, impact resistance and fatigue life of PLA composites through bridging effects, crack deflection and effective stress transfer. For instance, the addition of chopped glass fibers or carbon fibers can increase the stiffness of PLA by several times, reaching a mechanical level comparable to that of human cortical bone; magnesium alloy fibers not only enhance mechanical properties but also neutralize the acidic substances produced by PLA degradation and release magnesium ions to promote osteogenesis; while PVDF and other piezoelectric fibers can give the material electrical activity, generating microcurrents under mechanical stimulation in the body, further stimulating cell proliferation and bone tissue regeneration. Moreover, many fibers (such as bio-ceramic fibers, hydroxyapatite fibers) have excellent biological activity and bone conductivity, which can accelerate cell adhesion, proliferation and mineral deposition on the material surface, and promote the formation of new bone in the defect area.

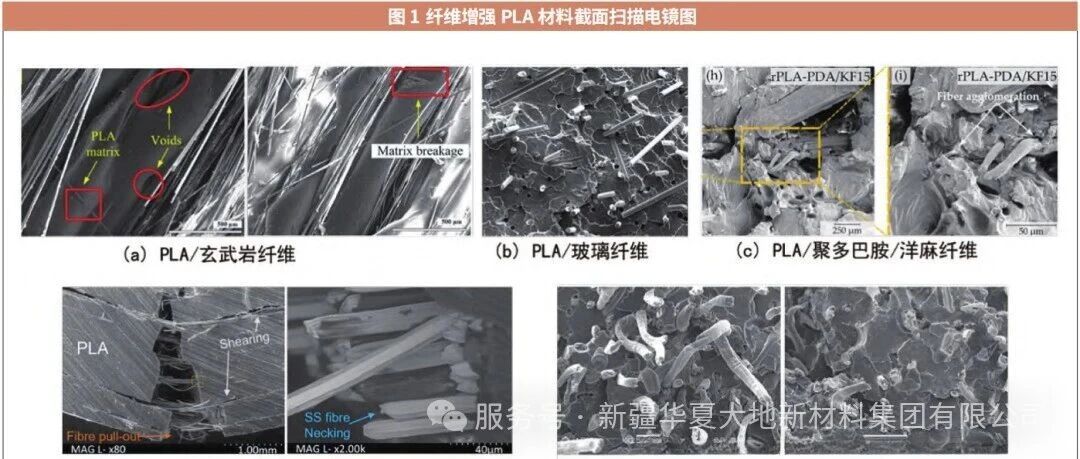

Apart from the type of fibers, their morphological parameters (length, orientation, content) and dispersion state also have a significant impact on the performance of the composite materials. Continuous fibers and fibers arranged in a specific direction usually exhibit better reinforcing effects than short-cut random fibers; the interface bonding strength between the fibers and the matrix directly determines the stress transfer efficiency and the final mechanical properties. Therefore, the optimization of fiber surface modification (such as silanization, polymer grafting) and composite processes (such as melt blending, solution composite molding, 3D printing) is of crucial importance.

Although fiber-reinforced PLA composite materials have shown great potential for application in devices such as bone plates, screws, and tissue engineering scaffolds, they still face several challenges at present: Some fibers (such as carbon fibers and certain synthetic polymer fibers) degrade slowly, which may lead to long-term residue and foreign body reactions; the thermal sensitivity and water absorption of natural fibers pose difficulties for processing; high-content fibers are prone to agglomeration, affecting the uniformity and mechanical reliability of the materials; and there are still technical bottlenecks in the preparation of complex three-dimensional porous structures and the controlled spatial distribution of fibers.

Future research should focus on developing new types of high-strength fibers that can be completely absorbed by the body, optimizing surface functionalization strategies to improve the fiber-matrix interface, developing advanced biomimetic composite manufacturing technologies (such as multi-material 3D printing, electrospinning-melt deposition combination), and systematically conducting long-term in vivo experiments to evaluate their degradation behavior and biological safety, ultimately promoting the large-scale application of fiber-reinforced PLA composite materials in clinical bone repair.