1 What is polylactic acid fiber?

Polylactic acid (PLA) is a new type of biodegradable material. It is made from starch raw materials derived from renewable plant resources (such as corn). The starch raw material is converted into glucose through saccharification, and then lactate with high purity is produced through the fermentation of glucose and certain bacteria. Subsequently, poly(lactic acid) with a certain molecular weight is synthesized through chemical synthesis methods. It has excellent biodegradability and can be completely degraded by microorganisms in nature after use, ultimately generating carbon dioxide and water, thus not polluting the environment. This is very beneficial for environmental protection and is recognized as a friendly environmental material.

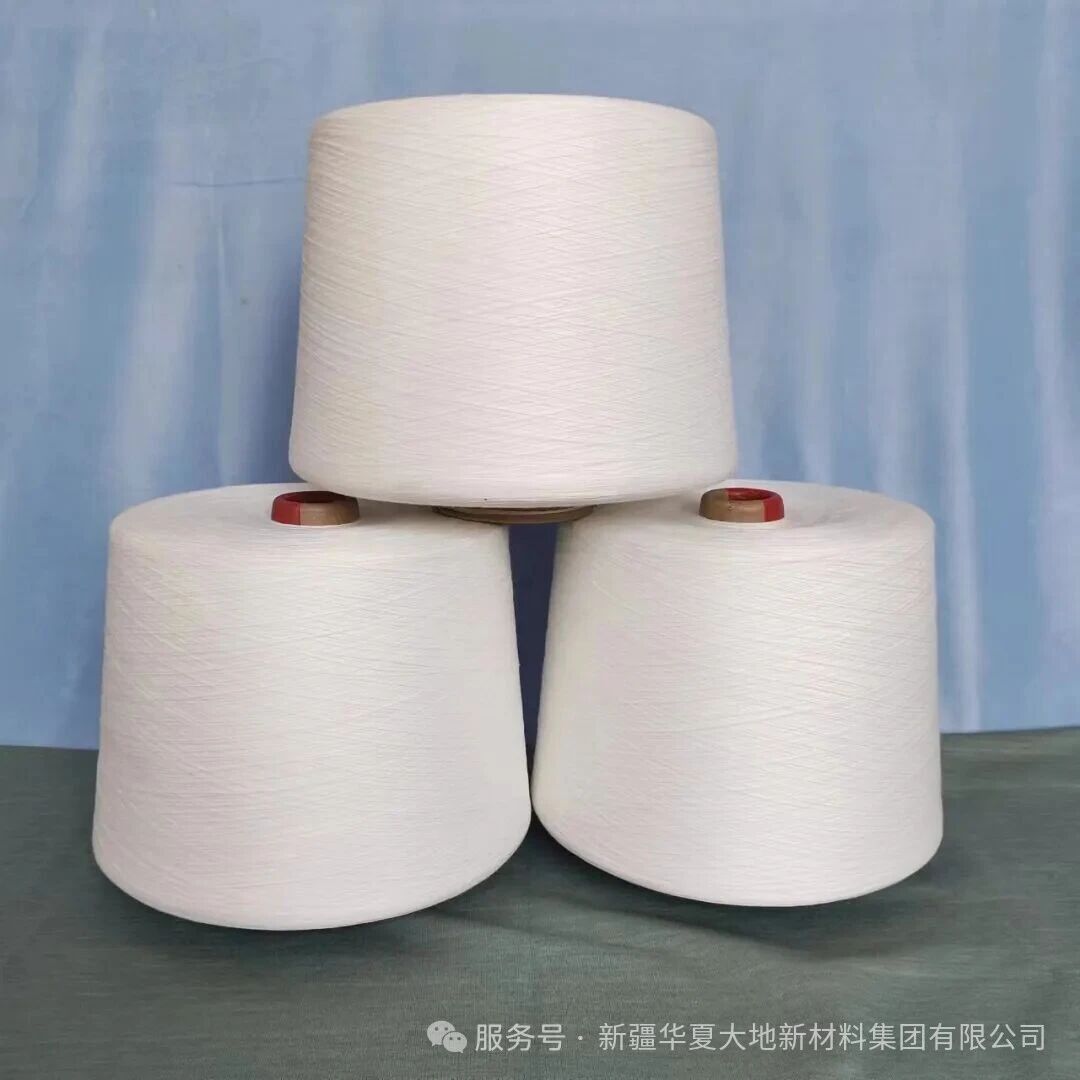

The raw material for producing polylactic acid (PLA) fibers, lactic acid, is derived from corn starch. Therefore, these fibers are also called corn fibers. They can be made from sugar beets or grains through glucose fermentation to reduce the cost of preparing lactic acid polymers. [2] High molecular weight PLA can be obtained through chemical polymerization of lactate cyclic dimer or direct polymerization of lactic acid. Products made from PLA have good biocompatibility and biodegradability, as well as antibacterial and flame-retardant properties. Among degradable thermoplastic high molecular materials, PLA has the best heat resistance.

The compatibility and biodegradability are excellent. Poly(lactic acid) is also widely used in the medical field, such as the production of disposable infusion devices, non-detachable surgical sutures, etc. Low-molecular-weight poly(lactic acid) is used as a drug sustained-release packaging agent, etc.

Polylactic acid (PLA) not only possesses the basic characteristics of biodegradable plastics, but also has its own unique properties. The strength, transparency and resistance to climate change of traditional biodegradable plastics are all inferior to those of ordinary plastics.

Polylactic acid (PLA) has similar basic physical properties to petrochemical synthetic plastics. That is to say, it can be widely used to manufacture various application products. PLA also has good luster and transparency, comparable to the films made from polystyrene, and is something that other biodegradable products cannot offer.

Polylactic acid (PLA) has the best tensile strength and ductility. PLA can also be produced through various common processing methods, such as melting extrusion molding, injection molding, film blowing molding, foaming molding, and vacuum molding. It has similar molding conditions to widely used polymers. Moreover, it has the same printing performance as traditional films. Therefore, PLA can be used to manufacture various application products according to the needs of different industries.