Poly(lactic acid) medical materials project

In the wave of green technology and sustainable development, polylactic acid (PLA), as a biogenic and biodegradable polymer material, is triggering a green revolution in the medical field. PLA is a fatty acid-based polyester formed by the polymerization of lactate molecules. Its monomer is 2-hydroxypropionic acid, and it has two enantiomers: L-lactic acid and D-lactic acid.

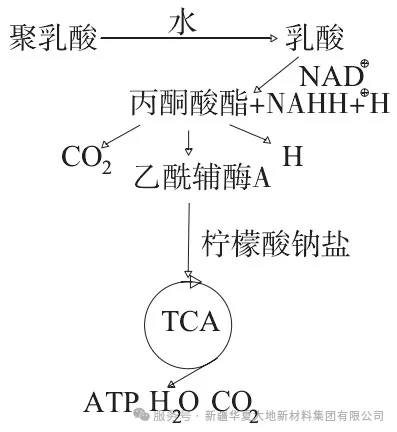

From surgical sutures to drug-controlled release systems, polylactic acid has brought revolutionary solutions to the medical industry with its outstanding performance. Polylactic acid has excellent biocompatibility and will not trigger an immune response when implanted in the human body. What's more, it can be hydrolyzed into lactic acid in the body and eventually be absorbed by the human body through normal metabolic pathways, without the need for a second surgery to remove it, significantly reducing the burden on patients.

With the development of modern medicine, due to the excellent mechanical and physical properties, outstanding biocompatibility and degradability of PLA materials, PLA-based materials have achieved significant application significance in fields such as drug carriers, bone fixation, and biological scaffolds.

Project Introduction Feature:

★Biocompatibility

Compatible with human tissues, and does not easily cause inflammation or rejection reactions.

★ Controllable Degradation Cycle

The degradation rate and tissue repair are synchronized through the regulation of molecular structure.

★Stable mechanical performance

It has the appropriate strength and elasticity to meet the requirements of surgical fixation and support.

★Antibacterial and anti-allergic

Fiber products have a naturally weak acidity that inhibits the growth of bacteria and reduces the risk of infection.

★ Processing Adaptability

It can be formed through various processes such as spinning and injection molding, and is easy to be modified for functionalization.

Application:

Surgical sutures and dressings: Polylactic acid is used to manufacture absorbable surgical sutures and wound dressings. After the material degrades, no additional surgery is required for removal.

Tissue engineering and drug sustained-release: As the core material for tissue engineering scaffolds, it supports cell growth and enables drug sustained-release functionality.

Orthopedic implants: Applied to absorbable bone plates, screws, etc. as orthopedic fixation devices. They gradually degrade as the bone heals after the surgery.

Interventional treatment devices: include biodegradable vascular stents, hemostatic clips, etc., reducing the long-term retention risk of traditional metal devices.

Disposable hygiene products: Used for infusion bags, infusion tubes, medical gauze, bandages, mattresses, diapers, etc., they are both environmentally friendly and safe.

Anti-adhesion isolation material: Manufactured as an absorbable anti-adhesion film, it effectively prevents postoperative tissue adhesion.

The emergence of polylactic acid materials not only addresses the drawbacks of traditional medical materials such as "poor degradability and high rejection rate", but also responds to the trend of environmentally friendly medical care with its "green and degradable" characteristics. In the future, with technological upgrades, it will unlock new possibilities in more specialized fields, bringing safer and more convenient treatment experiences to patients and doctors.

PLA - Medical Supplies

On December 31, 2021, the Ministry of Industry and Information Technology released the "Guidance Catalogue for the First Batch Application of Key New Materials (2021 Edition)", covering five categories of materials including advanced basic materials, advanced non-ferrous metals, advanced chemical materials, key strategic materials, and frontier new materials, totaling 304 types of materials. Among the advanced chemical materials, PLA was included, with its application fields being biomedicine and high-performance medical equipment.

PLA has excellent biocompatibility, is highly safe for the human body and can be absorbed by tissues. In addition, its excellent physical and mechanical properties make it widely applicable in the field of in-body medical materials. Besides disposable medical masks, gloves, bed sheets, pads, medicine boxes, and containers, it is also widely used in areas such as absorbable screws, absorbable surgical threads, fiber-woven materials or membrane materials for human tissue repair, fracture internal fixation materials, ophthalmic implant materials, and tissue engineering scaffold materials.

In countries like Europe and America, it has been used as an alternative to stainless steel and is widely employed as a new type of orthopedic internal fixation material such as bone screws and bone plates. Its property of being absorbed and metabolized by the human body enables patients to avoid the pain of undergoing another surgery.

Medical PLA can also be used as a drug-controlled-release material. It has special application value in the upgrading and development of modern drugs and dosage forms, such as drug molecule encapsulation and sustained-release/controlled-release preparations, vaccine encapsulation, and sustained-release/controlled-release preparations for targeted implantation of drugs. In addition, bio-level PLA obtained through enzymatic or whole-cell catalytic direct synthesis has certain prospects in the manufacturing of medical PLA materials in the future. However, the existing technical level, product polymerization degree and purity, etc., need to be further improved.