Poly(lactic acid) express packaging material project

Polylactic Acid Express Packaging: A Green Solution to End "White Pollution" In today's rapidly developing express delivery industry, the environmental issue of packaging materials has become increasingly prominent. The emergence of polylactic acid (PLA) materials has provided a brand-new path for reducing plastic and carbon emissions in express packaging, redefining green logistics with its degradable characteristics.

Today, with the growing environmental awareness, the packaging industry is also actively seeking sustainable development solutions. Polylactic acid (PLA), as a biogenic and degradable material, is gradually emerging and becoming a new favorite in the packaging field.

On March 12th, Premier Li Qiang of the State Council held a State Council executive meeting and reviewed and approved the "Decision (Draft) on Amending the <Regulations on Express Delivery>". This measure is of great significance. It specifically modifies the <Regulations> regarding express packaging issues, aiming to promote the green, reduced, and recyclable packaging of express delivery, and help accelerate the formation of green production and lifestyle.

The meeting clearly stated that systematic and collaborative governance should be adhered to. On one hand, the main responsibility of courier enterprises should be strengthened; on the other hand, guidance and regulation should be enhanced for upstream manufacturers, merchants and downstream consumers, and a full-chain governance approach should be promoted. At the same time, comprehensive supportive policies for the green transformation of courier packaging should be improved, effectively reducing operational costs such as packaging, recycling, cleaning and allocation, fully mobilizing the enthusiasm of all parties, and creating a favorable social atmosphere for green development.

The revision of the "Interim Regulations on Express Delivery" this time not only affects the development of the express delivery industry, but is also closely related to each of us. This is a transformation of lifestyle. By standardizing packaging and encouraging recycling, it can not only reduce resource waste, but also promote enterprise innovation, ultimately making the express delivery more efficient and the environment cleaner. I believe with the joint efforts of all enterprises, we will surely be able to make the express delivery industry operate efficiently while adding more green vitality to the earth and moving towards a brighter green future.

I. Advantages of Polylactic Acid in the Packaging Field

Biodegradability: One of the greatest advantages of polylactic acid is its excellent biodegradability. Traditional plastics are difficult to degrade in the natural environment and often take hundreds of years to do so, leading to severe "white pollution". However, polylactic acid can decompose into carbon dioxide and water within a few months to several years in specific environments such as composting, thus re-entering the natural cycle and significantly reducing the burden on the environment.

Excellent mechanical properties: Polylactic acid has high strength and stiffness, which can meet the basic mechanical requirements of most packaging. It can be made into films with certain toughness, sturdy sheets or formed products, ensuring the safety of the product during packaging, transportation and storage.

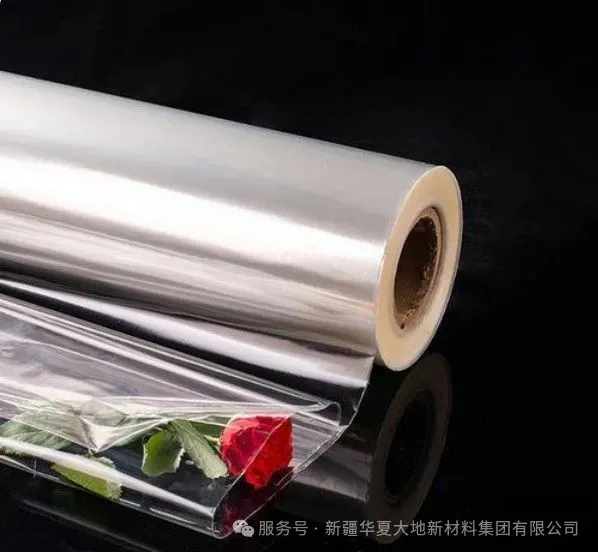

Outstanding transparency and gloss: The packaging materials made of polylactic acid have good transparency, even comparable to traditional glass paper and PET. This enables the product to be clearly displayed after packaging, enhancing the visual appeal of the product. At the same time, its glossiness is also high, making the packaging look more beautiful.

Gas and water barrier properties: Poly(lactic acid) has certain barrier properties against oxygen and water vapor, which can effectively delay the oxidation and moisture absorption of food and other products, and extend the shelf life of the products. This characteristic makes it have significant application value in the field of food packaging.

Antibacterial properties: Poly(lactic acid) can form a weakly acidic environment on the product surface, providing antibacterial and mold prevention capabilities. If other antibacterial agents are used as an aid, the antibacterial rate can reach over 90%, and it can be used for antibacterial packaging of products, effectively maintaining the quality of the products.

Thanks to its numerous advantages, poly(lactic acid) has demonstrated great potential in the packaging field, and numerous successful application cases have proved its feasibility. Although there are still some problems, with the continuous progress and innovation of technology, these difficulties are expected to be gradually resolved. It is believed that in the near future, poly(lactic acid) will be more widely applied in the packaging field, playing an important role in promoting the green and sustainable development of the packaging industry.

Project Introduction

Core characteristics: Dual online of environmental protection and performance

1. Environmentally friendly, with no burden on degradation

PLA materials can completely decompose into carbon dioxide and water within 6-12 months under composting conditions. This solves the "white pollution" problem of traditional plastic packaging at its root, making the courier packaging "originating from nature and returning to nature".

2. Mechanical properties are suitable for logistics needs

It has high impact resistance and flexibility. Through blow molding, thermoplastic, etc., it can be processed into: - Foam fillers for pressure resistance, protecting fragile items during transportation; - Torn-resistant films/plates, meeting the strength requirements of courier bags, tapes, etc.

3. Functional advantages precisely match scenarios

Balance of permeability and barrier: PLA films can adjust the permeability of oxygen and water vapor, extending the freshness preservation period of fresh goods;

Natural antibacterial property: The weakly acidic surface environment inhibits bacterial growth, and after adding antibacterial agents, the antibacterial rate exceeds 90%, reducing the risk of product contamination.

Typical application: Full-scenario implementation from packaging to recycling

Buffer filling material: PLA foaming material replaces traditional EPS foam, lightweight and impact-resistant, and can be composted and degraded after disposal;

Biodegradable express bags: Express bags made by compounding PLA with starch-based materials, with strength comparable to PE plastic bags, and can be industrially composted after use;

Recycling packaging solution: Logistics enterprises pilot PLA recycling boxes, which are disinfected by ultraviolet rays and reused, naturally degrade after being scrapped, achieving a "zero-waste" logistics closed-loop.

The innovative technology for poly(lactic acid) packaging aims to balance environmental protection and practicality, and is gradually replacing traditional plastic packaging. In the future, with technological upgrades and cost optimization, it will become the core support of green logistics, making each courier delivery more environmentally friendly and reassuring.

In recent years, with the upgrading of "plastic ban" in many places, the use of non-degradable plastic bags and disposable tableware is explicitly prohibited in many scenarios, and the ban has been extended to the field of courier packaging. The demand for poly(lactic acid) in the courier packaging industry has soared. The improvement of consumers' environmental awareness, especially the strong preference of the younger generation for sustainable products, has further driven the market demand for poly(lactic acid) products. At the same time, the material modification technology is constantly developing. Through methods such as blending and nanotechnology, the brittleness and heat resistance of poly(lactic acid) are improved, expanding its application scenarios in courier packaging and other fields. It can be predicted that poly(lactic acid) courier packaging will, with its environmental protection characteristics and practical performance, continuously drive the logistics industry to make a big step towards greenness, making each package transportation more sustainable and contributing to protecting the Earth's home.