Recently, a research team from the Department of Chemistry at the University of Coimbra in Portugal, the Polytechnic Institute of Leiria and other research institutions successfully developed a brand-new fully biobased and biodegradable material composite using PHBV, polylactic acid, chitosan, essential oils, bio-plasticizers and phycocyanin, specifically designed for cosmetic packaging applications. The related research results were published in Scientific Reports, a journal under the Nature group. This research is part of the NABIA and Embalagem do Futuro (Future Packaging) projects sponsored by the European Union and the Portuguese government.

The precise construction of the innovative material system:

The precise construction of the innovative material system:

This new material composite employs a six-component system design, with polyhydroxybutyrate-co-valerate (PHBV) and polylactic acid (PLA) as the main polymers in a ratio of 70:30. This ratio has been meticulously optimized to achieve the best performance balance.

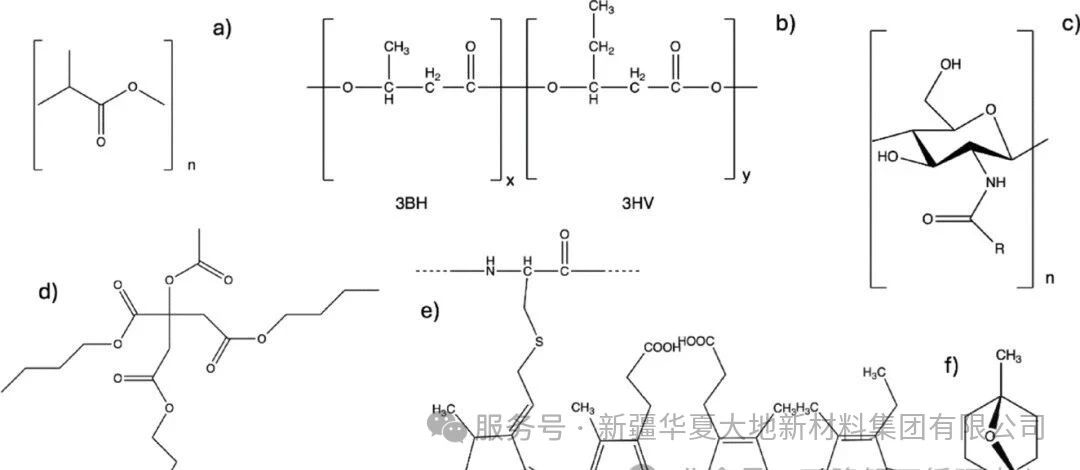

Figure: Chemical structures of the biomaterials used in the selected composite material formulations. (a) Poly(lactic acid) (PLA); (b) Poly(hydroxybutyrate-co-valerate) (PHBV); (c) N-acetylated chitosan (CS); (d) Acetyl tri-n-butyl citrate (ATBC); (e) Phycocyanin (Pgm); (f) Eucalyptol (a representative molecule of the used plant oil) (EO)

PHBV, as an important member of the polyhydroxyalkanoates (PHAs) family, is produced by microorganisms using different carbon source substrates and possesses natural hydrophobicity and moisture resistance. Its Young's modulus is 3-6 GPa, tensile strength is 22-34 MPa, and its melting point, crystallinity, and glass transition temperature are comparable to those of polypropylene and polyethylene. X-ray scattering analysis shows that PHBV maintains a high degree of crystallinity in the composite material and forms a stable crystal structure.

PLA, as one of the most widely used bio-based thermoplastic polyesters, is prepared from natural resources and has excellent optical, thermal, and mechanical properties. The PLA used in the study is amorphous and mainly dispersed in the amorphous region of PHBV in the composite material. This structure helps improve the processing performance and mechanical properties of the overall material.

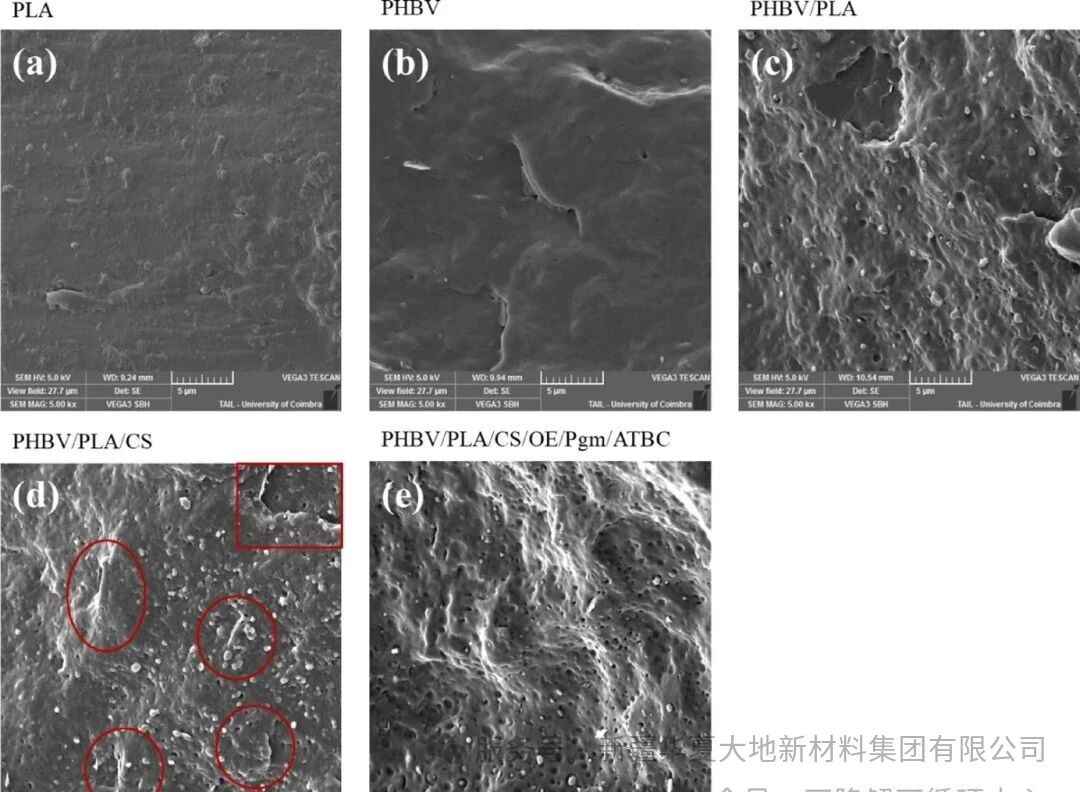

Chitosan, the second most abundant natural polymer on Earth, is extracted from various sources in millions of tons annually. The research team ground chitosan to an average particle size of 0.71 ± 0.2 mm and added it as a reinforcing filler to the composite material. Scanning electron microscopy analysis shows that chitosan fibers were introduced into the polymer matrix, but holes and insufficient interface bonding were still visible, presenting a two-phase coexistence structural feature.

Figure: Scanning electron microscopy (SEM) cross-sectional images: pure PLA (a), pure PHBV (b), PHBV/PLA formulation (c), PHBV/PLA/CS formulation, where the combination of CS fibers (red circle) and the position where CS was pulled out (rectangular box) can be observed (d), and PHBV/PLA/CS/OE/Pgm/ATBC (e)

Figure: Scanning electron microscopy (SEM) cross-sectional images: pure PLA (a), pure PHBV (b), PHBV/PLA formulation (c), PHBV/PLA/CS formulation, where the combination of CS fibers (red circle) and the position where CS was pulled out (rectangular box) can be observed (d), and PHBV/PLA/CS/OE/Pgm/ATBC (e)

The Synergistic Effect of Functional Additives

Triacetin (ATBC) plays a crucial role as a plasticizer in the formula, accounting for 10% of the total composition. By reducing the intermolecular forces between polymer chains and increasing the mobility of chain segments, ATBC enhances the flexibility and processability of the material. Differential scanning calorimetry (DSC) results show that the addition of ATBC lowers the glass transition temperature of the composite material to approximately 54°C (compared to about 60-62°C without it), confirming its plasticizing effect.

The addition of essential oils not only imparts a natural fragrance to the material but also reduces the water vapor permeability. The essential oils used in the study mainly consist of monoterpenes such as limonene and eucalyptol. Despite their content being only 1%, they have a positive impact on the material's flexibility and sensory properties.

Phycocyanin, a natural blue pigment, is also added to the formula at a 1% ratio. This natural pigment from spirulina not only provides an attractive blue appearance but also demonstrates the stability of natural pigments during high-temperature processing. At a processing temperature of 205°C, phycocyanin undergoes some degradation and color change, but still maintains a visible blue appearance.

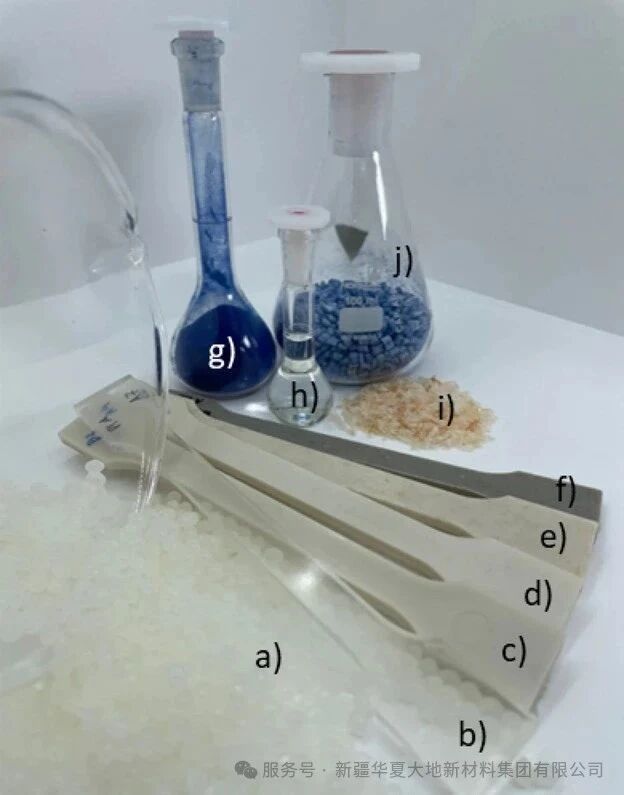

Figure: Biomaterials used in the selected composite material formula: (a) PLA particles; (b) PLA sample; (c) PHBV sample; (d) PHBV/PLA sample; (e) PHBV/PLA/CS sample; (f) PHBV/PLA/CS/phycocyanin (Pgm)/ATBC/essential oil (OE) sample; (g) phycocyanin; (h) ATBC/plant oil solution; (i) chitosan; (j) PHBV/PLA/CS/phycocyanin (Pgm)/essential oil particles

Figure: Biomaterials used in the selected composite material formula: (a) PLA particles; (b) PLA sample; (c) PHBV sample; (d) PHBV/PLA sample; (e) PHBV/PLA/CS sample; (f) PHBV/PLA/CS/phycocyanin (Pgm)/ATBC/essential oil (OE) sample; (g) phycocyanin; (h) ATBC/plant oil solution; (i) chitosan; (j) PHBV/PLA/CS/phycocyanin (Pgm)/essential oil particles

Outstanding overall performance.

Mechanical property tests revealed that composites with different formulations exhibited distinct performance characteristics.

The basic PHBV/PLA mixture demonstrated a tensile strength of 32 MPa and a Young's modulus of 804 MPa. After the addition of chitosan, the Young's modulus increased to 871 MPa, indicating an enhanced resistance to deformation, but the tensile strength slightly decreased to 25 MPa. The complete six-component system, under the plasticizing effect of ATBC, showed further reductions in tensile strength and modulus compared to the aforementioned two formulations, while the elongation at break significantly increased. The overall tensile behavior overlapped with the typical range of PE and some PP.

Thermal stability analysis revealed the processing window of the materials. Thermogravimetric analysis (TGA) indicated that pure PLA had the highest thermal stability, with a 2% weight loss temperature of 308°C. The initial degradation temperatures of PHBV and various composites were concentrated in the range of 255-262°C. This temperature range provided a sufficient safety margin for the melt processing of the materials.

Adaptability verification of advanced processing technology

The research team verified the industrial application potential of the material through various processing techniques. The twin-screw extrusion experiment was conducted using a Werner & Pfleiderer ZSK25 × 38D co-rotating twin-screw extruder with a screw diameter of 25 mm and a processing temperature range of 150-180°C. The melt flow rate (MFR) test showed that the MFR value of PHBV was 13.9 g/10 min, while that of PLA was 42.7 g/10 min. The MFR value of the PHBV/PLA mixture was between the two, indicating that it still maintained good fluidity after mixing.

Injection molding was carried out using a BOY 22 A injection molding machine to prepare dumbbell-shaped specimens in accordance with ISO 527-2:2012. The injection parameters for each formula were adjusted within the range of 175-190°C, and the mold temperature was maintained at 40-60°C.

The verification of 3D printing technology demonstrated the material's potential in personalized packaging manufacturing. Using Piocreat G5 FGF melt granulation manufacturing technology, a prototype of a cosmetic packaging base was successfully printed at 205°C with a 1.8 mm nozzle at a speed of 20 mm/s. This temperature was determined as the optimal process parameter through gradual adjustment starting from 185°C.

Contact angle tests revealed the surface wetting characteristics of the materials.

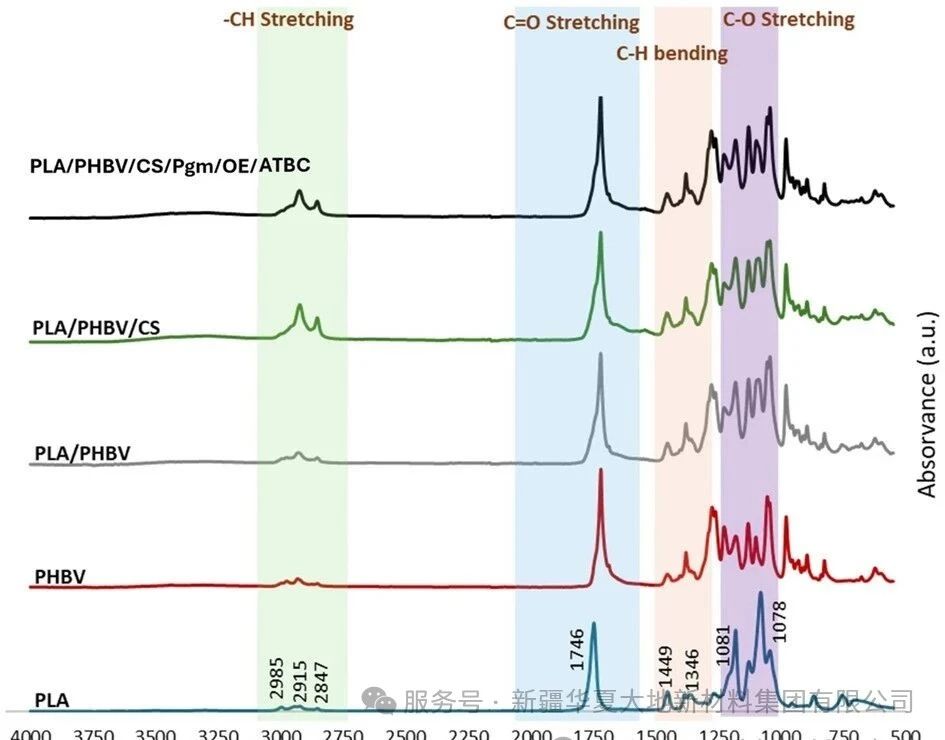

All developed composites exhibited hydrophilic behavior, with contact angles all less than 90°. The contact angle of pure PLA was 72.1°, and that of PHBV was 77.2°. The contact angle measured for the complete formulation was higher than those of the aforementioned two formulations but still below 90°, showing hydrophilic characteristics and being more prone to hydrolytic degradation. Fourier transform infrared spectroscopy (FTIR) analysis indicated that no strong chemical interactions were formed among the components, and they mainly existed in a physical blend form. The characteristic peaks of PLA included C-H stretching vibration near 2900 cm⁻¹ and C=O stretching vibration at 1746 cm⁻¹. The characteristic peaks of PHBV appeared at 2968 and 2913 cm⁻¹ (C-H stretching) and 1720 cm⁻¹ (C=O stretching).

Figure: FTIR spectra of the developed formulations: PLA, PHBV, PHBV/PLA, PHBV/PLA/CS, and PHBV/PLA/CS/OE/Pgm/ATBC

Industrialization Prospects and Technical Challenges

The global cosmetics packaging market is continuously growing and is expected to reach 51 billion euros by 2032. With the increasing environmental awareness of consumers and the increasingly strict regulatory policies, the market demand for bio-based packaging materials is growing rapidly. Polyethylene and polypropylene materials are mainly used in cosmetics and detergent packaging and are widely applied in various sub-sectors of rigid and flexible packaging solutions. This newly developed bio-based composite material has comparable performance to traditional materials, providing a feasible alternative for the industry. However, the industrialization of the material still faces some technical challenges. Research shows that while the plasticizer ATBC improves the material's flexibility, it also leads to a decrease in mechanical strength. This contradiction needs to be balanced by optimizing the formula ratio or improving the processing technology. In addition, the color stability of natural pigments during high-temperature processing still needs to be further improved. In terms of 3D printing technology, the temperature during the melt granulation manufacturing process needs to be precisely controlled. Excessively high temperatures can cause component degradation, while excessively low temperatures can affect fluidity. The currently determined processing temperature of 205°C provides an important reference for subsequent process optimization. This research achievement represents a significant breakthrough in the field of bio-based packaging materials and provides a practical technical path for the cosmetics industry's transition to sustainable development. With the continuous improvement of process technology and further cost optimization, this fully bio-based material is expected to achieve commercial application in the next few years, promoting the entire packaging industry to move towards a more environmentally friendly and sustainable direction.