Recently, the People's Daily published an article titled "Biological Manufacturing: Converting Carbon Dioxide into Treasure", which reported on the conversion value of carbon dioxide as a raw material for biological manufacturing. The Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences has achieved breakthroughs in its synthesis into starch, sugars, etc. The progress of artificial carbon fixation and industrialization has contributed to the achievement of the carbon neutrality goal and sustainable development.

Synthetic starch sample

Biodegradable plastic tableware samples

Biodegradable plastic tableware samples

Microbial protein sample

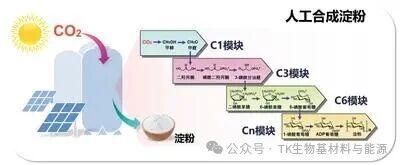

Schematic diagram of synthesizing starch from carbon dioxide using artificial methods.

The Laboratory of Artificial Synthesis of Starch at the Tianjin Industrial Biotechnology Institute of the Chinese Academy of Sciences.

The above pictures are all provided by the Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences.

Netizen: I recently read a news report that researchers are attempting to directly capture carbon dioxide from seawater and convert it into biodegradable plastics. Does this fall under the category of "biological manufacturing"? What else can carbon dioxide be transformed into?

Editor: Exactly, what you mentioned is precisely the current cutting-edge topic in science and technology - carbon dioxide is not only a greenhouse gas, but also a potential "carbon resource".

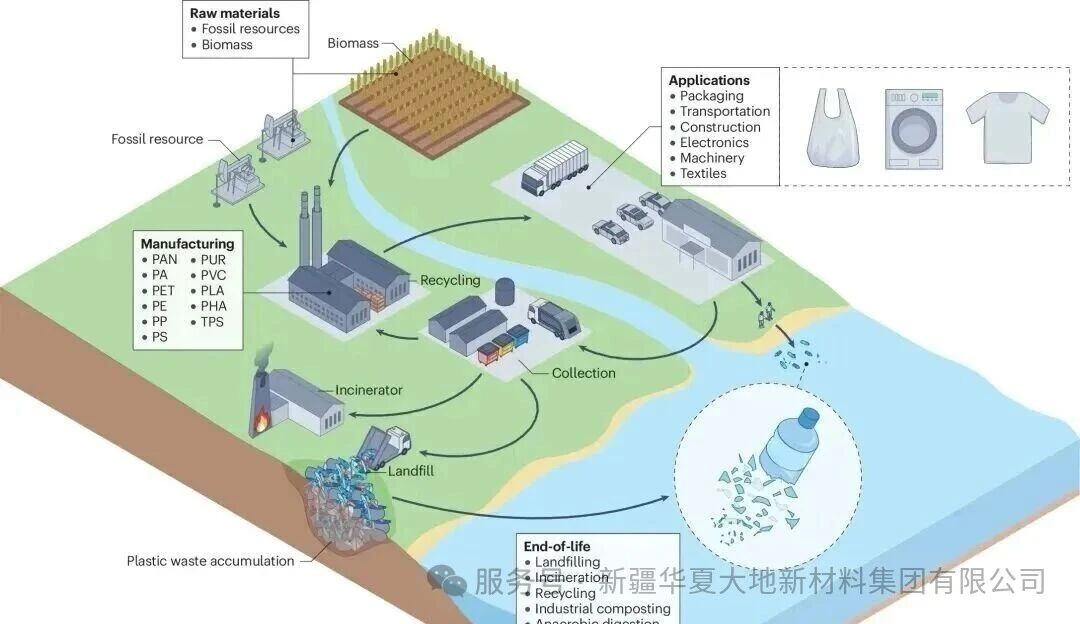

The "14-15" planning proposal suggests that "improve the new national system, adopt extraordinary measures, and comprehensively promote the research and development of key core technologies in key fields such as integrated circuits, industrial mother machines, high-end instruments, basic software, advanced materials, and biological manufacturing, achieving decisive breakthroughs." The biological conversion of carbon dioxide is a highly promising direction in the field of biological manufacturing. Carbon dioxide serves as the raw material for biological fixation and transformation, is an important participant in the global carbon cycle, and the organic substances produced through its conversion support the entire food chain. Through biotechnology, carbon dioxide can "transform" into starch, protein, fuel, and even degradable plastics.

In this issue of "Viewing the Frontiers", we have invited Cai Tao, a researcher from the Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences, to introduce the latest developments in the field of biological fixation and conversion of carbon dioxide.

Carbon dioxide is a greenhouse gas

and an important raw material for biological production

The carbon dioxide we exhale at every moment is a by-product of biological metabolism and a crucial part of the carbon cycle in nature. This invisible gas is also the focus of global climate governance.

Carbon dioxide acts like an "insulation blanket" covering the Earth's surface. When present in the appropriate amount, it can maintain the average temperature on the Earth's surface at around 15 degrees Celsius, making it possible for life to thrive. However, since the Industrial Revolution, human activities have intensified, and this "blanket" is becoming increasingly thick. The burning of fossil fuels and changes in land use have led to a continuous increase in the concentration of greenhouse gases in the atmosphere, causing global temperatures to rise continuously. As a result, there are a series of chain reactions such as accelerated melting of glaciers, rising sea levels, and frequent occurrence of extreme weather events.

In the face of this serious challenge, the international community has placed greater emphasis on carbon neutrality. Reducing emissions is one aspect of the response strategy. On the other hand, how to convert carbon dioxide into useful resources and shift from passive emission reduction to active utilization? This is the thinking of sustainable development.

In fact, carbon dioxide itself is an important participant in the global carbon cycle and is the third-generation raw material produced by living organisms. Driven by renewable energy, carbon dioxide can be transformed through biological conversion technologies and given a new "life" - turning into starch, proteins, fuels, and even degradable plastics. This "carbon conversion" practice is quietly taking place in laboratories and factories around the world.

From imitating nature to artificial creation, there is a new path for efficient conversion of carbon dioxide.

Nature itself is a master at converting carbon dioxide. About 3.5 billion years ago, primitive cyanobacteria began to fix and transform carbon dioxide, laying the foundation for the evolution of life on Earth. Today, the organisms on Earth that can convert and utilize carbon dioxide mainly fall into two categories: photosynthetic autotrophs (such as plants and algae) and chemosynthetic autotrophs (such as nitrate bacteria). They convert carbon dioxide into organic matter through different carbon fixation pathways. The most well-known of these is the Calvin cycle - this process provides the vast majority of the food and oxygen for humans, and its discoverer, Melvin Calvin, was awarded the Nobel Prize in Chemistry in 1961.

However, the carbon sequestration system in nature is not perfect. The key enzymes in the Calvin cycle lack "specificity" when capturing carbon dioxide, often mistakenly binding oxygen molecules, thereby initiating the energy-consuming photorespiration process, resulting in a decrease in carbon sequestration efficiency. This is like an inefficient production line that requires continuous remedial measures.

To enhance the efficiency of carbon dioxide utilization, scientists have attempted to "upgrade" this carbon sequestration process. By introducing a more efficient photorespiration alternative pathway into tobacco, they were able to successfully recover some of the lost carbon dioxide. By strengthening the "light protection" mechanism to reduce the inhibition on photosynthesis, this strategy has been verified successful in both tobacco and soybeans. Additionally, research teams have introduced additional carbon dioxide fixation pathways into plants, such as introducing the photorespiration alternative pathway into rice, which significantly increased the carbon fixation efficiency and yield.

But the real breakthrough came from breaking free from the limitations of nature and designing a completely new artificial carbon sequestration pathway from scratch. In 2016, German scientists designed and assembled the first carbon sequestration pathway that did not exist in nature - the CETCH cycle. Its carbon sequestration efficiency was significantly higher than that of the natural Calvin cycle. In 2021, researchers successfully created the POAP cycle, which consists of only 4 reaction steps and is the shortest known carbon sequestration path. In 2023, a German team further designed the THETA cycle and successfully "implanted" it into Escherichia coli, taking the first step towards moving complex artificial carbon sequestration pathways into cells. These breakthroughs provide a new path for efficient carbon dioxide conversion, marking a shift from simple imitation of nature to a new stage of autonomous design.

The industrialization path is gradually becoming clear

Promoting the improvement of biological carbon sequestration efficiency

At present, breakthroughs in basic research have led to a series of disruptive applications, and the industrialization path for carbon dioxide bioconversion is gradually becoming clear.

In 2021, the Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences and the Dalian Institute of Chemical Physics jointly achieved the first artificial full synthesis of starch from carbon dioxide without relying on photosynthesis in the world. This process combines chemical catalysis and enzymatic reactions to gradually convert carbon dioxide into starch. When combined with photovoltaic and electrolytic hydrogen production devices, this system can synthesize starch using sunlight, water and carbon dioxide, and its synthesis rate and theoretical energy conversion efficiency exceed those of crops like corn. Subsequently, the team of this institute also achieved precise synthesis of various sugar compounds such as glucose and mannitol from carbon dioxide in 2023.

Another approach is to transform microbial cells into "factories" to produce starch. Based on yeast as the "platform" cells, scientists have successfully constructed cell factories that can synthesize starch. The artificial synthesis of starch makes it possible for starch production to shift from the traditional agricultural planting model to an industrial workshop production model, and opens up a new technical route for synthesizing complex molecules using carbon dioxide as the raw material.

Protein is an indispensable nutrient for living organisms. Currently, although the global protein supply is still mainly derived from traditional animal and plant sources, microbial protein has also emerged. It can be synthesized using carbon dioxide or industrial waste gases as raw materials and has the unique advantage of "not competing with humans for food and not competing with farmland for land". In 2024, an American company announced that it would use soil bacteria and gas fermentation technology to convert recycled carbon dioxide into microbial protein. In China, Hebei Shoulang New Energy Technology Co., Ltd. has successfully developed a technology for converting industrial waste gases into feed protein through bacterial fermentation. In 2025, an industrial device for producing yeast protein from carbon dioxide was successfully put into operation in Inner Mongolia. These breakthroughs indicate that the industrial production path from carbon dioxide to protein is gradually becoming a reality, opening up a new direction for ensuring future protein supply and promoting green and low-carbon development.

In addition to synthesizing biological macromolecules such as starch and proteins, carbon dioxide can also be transformed through biological processes to produce various chemicals, opening up new low-carbon or even negative-carbon pathways for the chemical industry.

In the field of biofuels, several proof-of-concept studies on the biological conversion of carbon dioxide have been achieved. Researchers have utilized yeast to convert acetic acid obtained through electrocatalytic carbon dioxide conversion into fatty acids, β-farnesene and other poly-carbon molecules, providing a new approach for the production of green biofuels.

In the field of biodegradable plastics, research is advancing towards the goal of achieving efficient and large-scale production. In 2025, researchers constructed an "artificial marine carbon cycle system", which directly captured carbon dioxide from seawater and converted it into completely biodegradable plastics, demonstrating the industrialization possibility of converting seawater into green materials and providing a new solution to the problem of ocean acidification.

Unveiling the intrinsic mechanism of carbon dioxide biotransformation and breaking through the rate and energy efficiency limits of natural carbon sequestration systems is a globally recognized major frontier scientific issue, attracting extensive attention from scholars worldwide. Exploring new pathways, mechanisms, and functional elements of carbon dioxide biotransformation not only enables the revelation of unknown carbon sequestration metabolic networks in nature and expands human understanding of life metabolism, but also provides a brand-new theoretical basis and technical strategies for the artificial design of efficient carbon sequestration systems, thereby promoting a revolutionary improvement in the efficiency of biological carbon sequestration. The exploration in this field holds profound scientific value and strategic significance for ultimately achieving the goal of carbon peak and carbon neutrality. In the future, these innovations from the laboratory are expected to reshape our material production model and gradually build a more sustainable carbon cycle picture.