In August 2025, a study published in the International Journal of Biomacromolecules demonstrated that scientists, through chemical pretreatment of rice husks, successfully enhanced the performance of polylactic acid (PLA) biocomposite materials, opening up new avenues for the development of sustainable materials. This research was funded by the University of Umm Qura in Saudi Arabia and aimed to address the dual challenges of agricultural waste management and the development of sustainable building materials.

Natural fibers such as rice husks and straw have hydrophilic hydroxyl (OH) groups and non-cellulose components (lignin and hemicellulose), which result in poor compatibility with hydrophobic polymers like polylactic acid (PLA). This leads to insufficient interface bonding in the composite materials, unstable mechanical properties, and susceptibility to degradation due to moisture. Previous studies on fiber-polymer composite materials have shown that the water absorption rate of the materials often exceeds 10% by mass after long-term immersion. However, there are few systematic reports on moisture control in the rice fiber/PLA system.

The core objective of this study is to enhance the interfacial bonding performance between rice straw fibers and the PLA matrix by removing the non-cellulose components from the fibers and modifying the surface properties of the fibers.

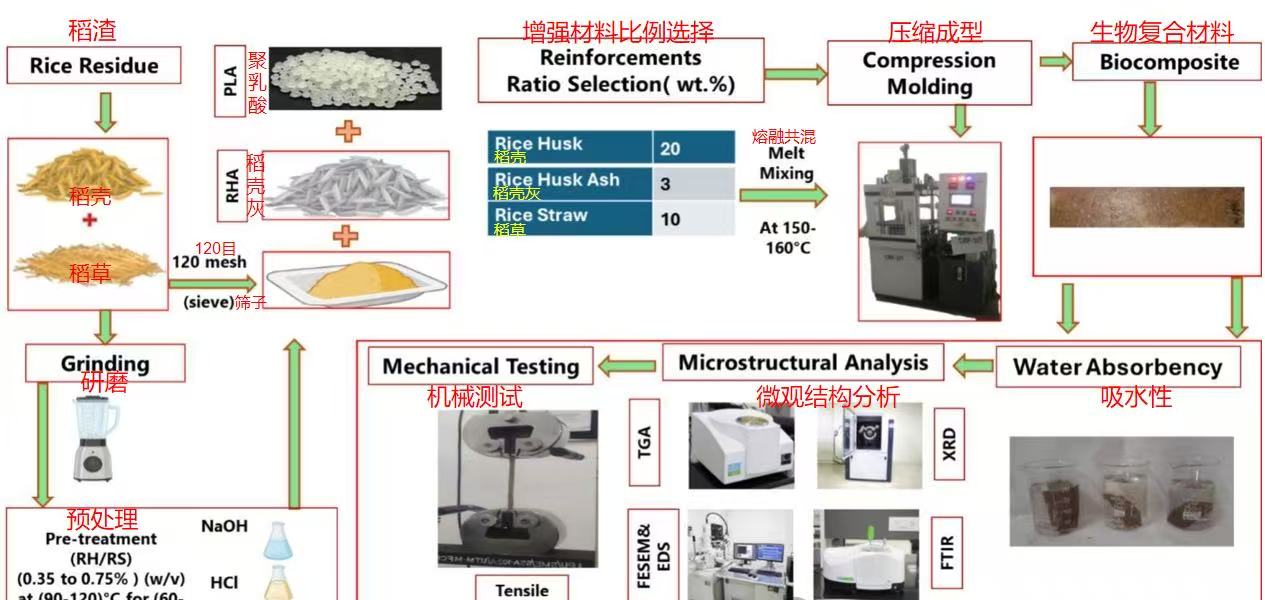

The researchers utilized rice husks, rice straw and other rice residues, and through the central composite design (CCD) system, optimized the concentration, temperature and time parameters of three chemical pretreatment agents, namely sodium hydroxide (NaOH), hydrochloric acid (HCl) and sulfuric acid (H₂SO₄). The results showed that the bio-composite material treated with NaOH performed the best in terms of thermal decomposition temperature, tensile strength and water absorption resistance.

Under optimized process conditions (0.55% NaOH, 105°C, 75 minutes), the thermal decomposition temperature of the biological composite material increased by 15%, and the ultimate tensile strength reached 35.6 megapascals (MPa), which was 8.2% higher than that of the composite material treated with HCl. Meanwhile, the water absorption rate of the NaOH-treated biological composite material within 24 hours was only 4.2%, achieving a balance between water resistance and biodegradability.

The research team employed a comprehensive set of characterization techniques including Fourier Transform Infrared Spectroscopy (FTIR), X-ray Diffraction (XRD), Energy Dispersive Spectroscopy (EDS), and Field Emission Scanning Electron Microscopy (FESEM) to reveal the mechanism by which NaOH treatment can selectively remove lignin and amorphous silica while retaining the crystallinity of cellulose, thereby improving the interface bonding performance of the composite materials.

Furthermore, the study also added rice husk ash as a 3% mass fraction filler to the composite material. This not only enhanced the thermal stability of the material but also reduced the incineration treatment of agricultural waste, thereby further improving the sustainability of the material.

The first author of the study, Bhupinder Singh, said: "By systematically optimizing the chemical pretreatment process, we not only enhanced the performance of the bio-composite materials, but also provided a new method for the high-value utilization of agricultural waste. This achievement is expected to promote the development of sustainable building materials and reduce the impact on the environment."

This research provides important theoretical and practical basis for the development of sustainable bio-composite materials, especially in the field of environmentally friendly architecture, such as the application of lightweight ceiling panels and tiles. In the future, the research team plans to further explore the long-term weather resistance of this material (such as UV aging, cold and hot cycles), and promote its application in industrial production.

Industry experts believe that this research achievement provides innovative solutions for addressing agricultural waste pollution and promoting the sustainable development of the construction industry, and is expected to be widely applied globally.