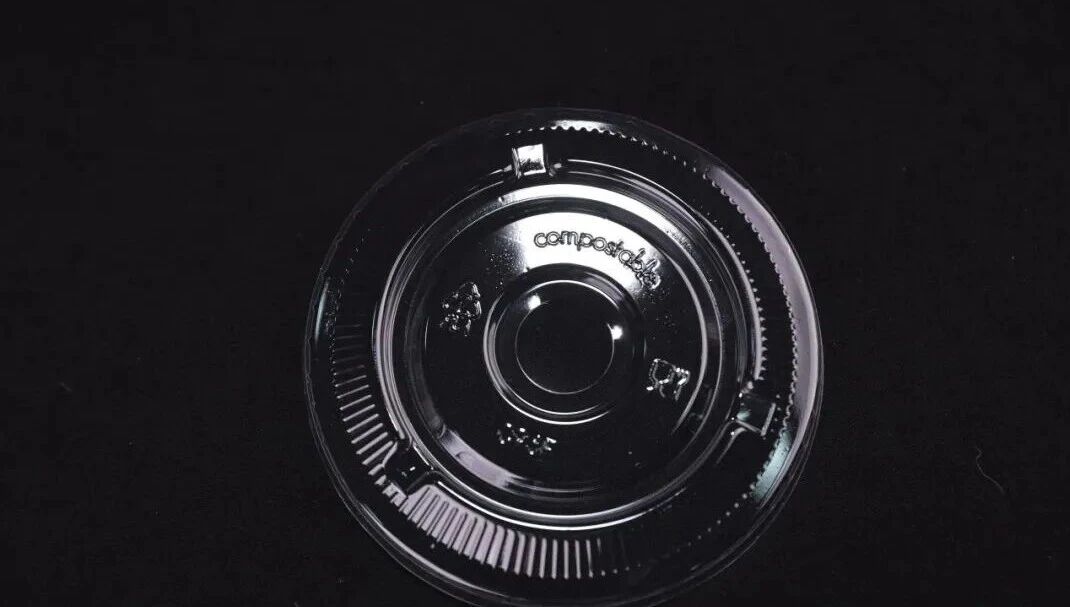

When plastic bags in supermarkets quietly change from "non-degradable" to "degradable", and when takeaway food containers come with the label "compostable", it is not difficult for us to notice that most of these products carrying the "green mission" are associated with two names - PLA and PBAT. In the current situation where global plastic restrictions are becoming stricter and the management of "white pollution" is urgent, why have these two materials stood out and become the absolute mainstream in the field of degradable plastics? Today, let's uncover their "core advantages".

The "Past and Present" of Biodegradable Plastics: From the Limitations of Starch to the Innovation of Materials

When it comes to degradable materials, many people will first think of starch. As one of the most abundant renewable resources in nature, starch is widely present in plants such as corn, potatoes, and sweet potatoes, with an annual production of several hundred million tons. It not only has a wide range of sources but also has a very low price, inheriting the "green gene" naturally.

However, starch is not perfect. Natural starch has a unique microcrystalline structure and granular structure, resembling a pile of hard small particles. It cannot be directly processed through thermoplastic methods to produce various shaped products. To make starch "obedient", it must undergo special treatment and be transformed into "thermoplastic starch" - by destroying the original crystalline structure, the starch molecules become more fluid, thus acquiring processing properties. However, the modified starch still has deficiencies in strength, water resistance, and other aspects, and is difficult to independently meet the complex requirements of various usage scenarios.

It was under such circumstances that PLA and PBAT, leveraging their respective "unique skills", gradually became the "main force" in the field of degradable plastics.

PBAT: The "Master of Balance" for Flexibility and Degradation, The Green Transformation of Petroleum-Based Materials

PBAT, the full name of which is Polybutylene Adipate - Terephthalic Acid Butylene Dicarboxylate, is a petroleum-based thermoplastic biodegradable plastic. Unlike bio-based materials derived from plants, its "birth" originated from the ingenious combination of three basic chemical raw materials - adipic acid (AA), terephthalic acid (PTA), and butanediol (BDO). These raw materials all come from the petrochemical industrial chain. This characteristic gives PBAT a unique advantage in raw material supply: relying on the mature petrochemical system, China has sufficient production capacity reserves for these three raw materials, laying a solid foundation for the large-scale production of PBAT.

If one word is used to describe PBAT, it would definitely be "flexible". It has excellent ductility and elongation at break, just like an elastic rubber band that can be stretched very long but is not prone to breaking. It is suitable for making products that require some elasticity. It also has good heat resistance and impact resistance, and can maintain a stable state even when facing temperature changes and minor impacts during daily use. This "combination of rigidity and flexibility" characteristic has enabled PBAT to shine in various fields such as packaging and agricultural mulch films - for example, shopping bags in supermarkets need to be stretch-resistant, and agricultural mulch films need to withstand wind and sun exposure. PBAT can easily handle these requirements.

More importantly, PBAT has excellent biodegradability. Even if it originates from petroleum-based materials, it can still be decomposed by microorganisms in the natural environment into carbon dioxide and water, ultimately returning to nature and leaving no "white waste". At the industrial level, PBAT is no longer a "rare item" in the laboratory: China has already mastered mature production technologies and equipment, and the production chain from raw materials to finished products is very complete. The production capacity is sufficient and the cost is controllable. This is why, under the impetus of the plastic restriction order, PBAT can rapidly "scale up" and become one of the most promising varieties in the degradable plastic market.

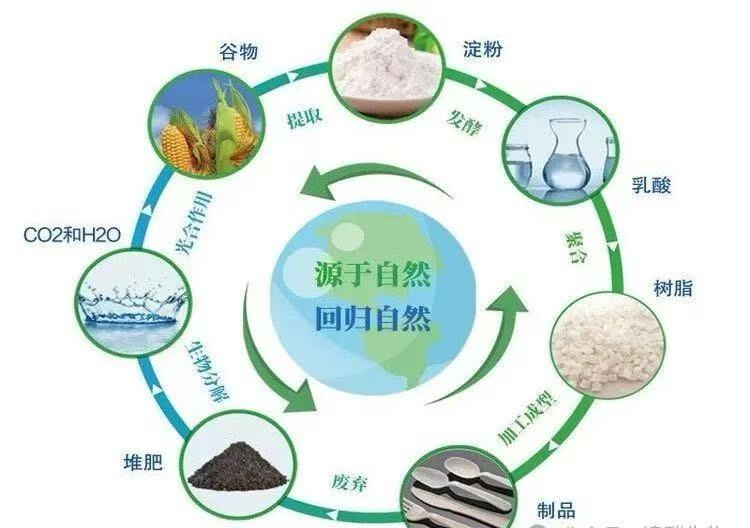

PLA: "Green Pioneers" - From Plants to Nature

If PBAT represents "flexibility and responsibility", then PLA (polylactic acid) is the "all-rounder" among degradable materials. As a representative of biobased degradable plastics, PLA has an inherently glamorous "background" - its raw material is corn, sugar cane and other plants rich in starch, which are converted into lactic acid through fermentation and then polymerized into polylactic acid. The entire production process is almost pollution-free, truly achieving the cycle of "coming from plants and returning to nature".

The advantages of PLA can be aptly described as "both martial and scholarly". In terms of performance, it boasts excellent biocompatibility (harmless to the human body and suitable for the medical field), thermal stability and solvent resistance. It is also very convenient to process and can be molded into various products through injection molding, blow molding and other techniques, just like traditional plastics. What's more remarkable is that the appearance and feel of PLA products are truly "top-notch" - with high gloss, good transparency, and a smooth texture when touched. Its heat resistance also far exceeds many degradable materials. The food containers and packaging films made from it are not only aesthetically pleasing but also highly practical.

Functionally, PLA also comes with its own "hidden capabilities": antibacterial properties, flame retardancy, and UV resistance. This enables its application scope to continuously expand - from everyday food packaging and shopping bags, to seed trays in agriculture, fibers in the textile industry, to absorbable sutures in the medical field and 3D-printed human tissue scaffolds. PLA can play a significant role in all these areas. As a "senior application" of synthetic biology in the field of materials, PLA has already proven with its strength that environmental protection and high performance can be achieved simultaneously.

The combination of two giants: PLA and PBAT's "golden partnership"

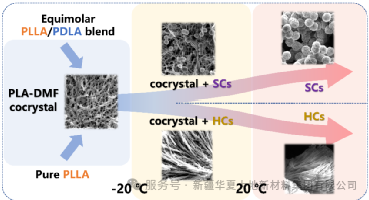

When considered individually, PLA and PBAT have their own advantages: PLA has high strength and good rigidity, but its toughness is slightly inferior; PBAT has excellent flexibility and strong extensibility, but it lacks rigidity. However, when they "join forces" and form a composite material through blending modification, the performance can achieve "1 + 1 > 2".

This composite material retains the stiffness and heat resistance of PLA while also possessing the flexibility and impact resistance of PBAT. It perfectly meets the dual requirements of "strength + toughness" for daily items such as plastic bags and lunch boxes. Moreover, the biodegradability of the two does not interfere with each other, and both can eventually complete degradation in the natural environment, truly achieving "no trace after use".

Nowadays, with the maturity of domestic production technology, the availability of raw material capacity, and the continuous promotion of policies such as the plastic restriction order, the costs of PLA and PBAT have been continuously decreasing, and the industrialization scale has been continuously expanding. Data shows that these two materials have occupied nearly half of the global biodegradable plastic market, and have become the undisputed "main force".

The Future Has Arrived: The "Golden Age" of Biodegradable Plastics

From "plastic restriction" to "plastic ban", from "difficult to degrade" to "recyclable", the relationship between humans and plastics is being redefined. In this green revolution, PLA (biobased) and PBAT (petroleum-based), although coming from different sources, have relied on their unique advantages and the "complementary and win-win" cooperation model to become the key to solving the "white pollution" problem.

In the future, with further technological breakthroughs, we may witness the emergence of more superior-performing and cost-effective biodegradable materials. But at least for now, PLA and PBAT have proven with their strength that environmental protection is not an excuse to sacrifice performance. Sustainable materials will eventually become the mainstream of the times.

The next time you pick up a biodegradable plastic bag, take a moment to look at its ingredient list - perhaps the one you are holding is the tiny force that could change the future of "white pollution".