A panoramic view of the PLA industry chain: How does a single corn kernel drive the green revolution of environmental-friendly materials?

If the industrial chain of PLA is compared to a "green cycle", then corn is the starting point, lactic acid is the bridge, caprolactone is the core, and the final polymer material is the endpoint. But each link in this chain hides the secrets of technological breakthroughs and industrial collaboration. Today, we will take you through the entire industrial chain of PLA, from raw material cultivation to end applications, to reveal how this green revolution starting from "corn" is reshaping the future of the plastic industry.

The "quad" of the PLA industrial chain

1. Raw material layer: "Green extraction" from corn to starch

Core raw material: Corn (or sugar cane and other plants) is converted into starch through starch extraction technology, and then fermented to produce glucose.

Technical highlights: Efficient enzymatic hydrolysis process and green separation technology ensure the purity of starch and production efficiency.

Key enterprises: JinDan Technology, China National Cereals, Oils and Foodstuffs Co., Ltd. Biotechnology, Fengyuan Biotechnology (China); NatureWorks (USA), etc.

2. Fermentation Layer: "Biological Refining" from Glucose to Lactic Acid

Core process: Utilizing lactic acid bacteria (such as bifidobacteria), glucose is converted into lactic acid through fermentation.

Technical challenges: Fermentation efficiency, purity of lactic acid (L-lactic acid vs D-lactic acid), and energy consumption control.

Industry trend: The demand for high optical purity lactic acid (such as L-lactic acid) is increasing, which drives the upgrading of fermentation technology.

3. Synthesis Layer: "Chemical Transition" from Lactic Acid to Caprolactone

Core reaction: Lactic acid undergoes dehydration condensation to form oligomers, which then undergo depolymerization and cyclization, followed by purification to obtain high-purity poly(lactide).

Technical barriers: The high-purity synthesis of caprolactone is the core bottleneck in PLA production. Only a few enterprises worldwide possess mature technologies (such as NatureWorks, JinDan Technology, etc.).

Current situation in China: The shortage of caprolactone supply, technical barriers, high costs, purity requirements, and market supply-demand imbalance are the core reasons restricting the production capacity of polylactic acid. To break through the bottleneck, it is necessary to accelerate the research and development of domestic technologies (such as catalyst optimization and process improvement), increase the self-sufficiency rate of caprolactone, and reduce the unit cost through large-scale production.

4. Aggregation Layer: The "Molecular Symphony" from Caprolactone to PLA

Core process: Caprolactone undergoes ring-opening polymerization under the action of a catalyst to form poly(lactic acid) (PLA).

Product classification: Injection molding grade, Film grade, Fiber grade, etc., meeting the requirements of various application scenarios.

Modification technology: Enhance the heat resistance and toughness of PLA through blending, copolymerization or adding toughening agents (the "modification revolution" of PLA - the transformation from brittle to strong).

The "Applied Symphony" of the PLA

Packaging field: From disposable tableware to high-end food packaging

Typical products: PLA food containers, straws, cling film, etc.

Market-driven: Global plastic restriction policies and the enhanced environmental awareness of consumers have led to situations where, for instance, China's "Opinions on Further Strengthening the Governance of Plastic Pollution" explicitly stipulates that by 2025, the consumption of non-degradable plastic products in key areas should be significantly reduced, thereby promoting the substitution of PLA for traditional plastics.

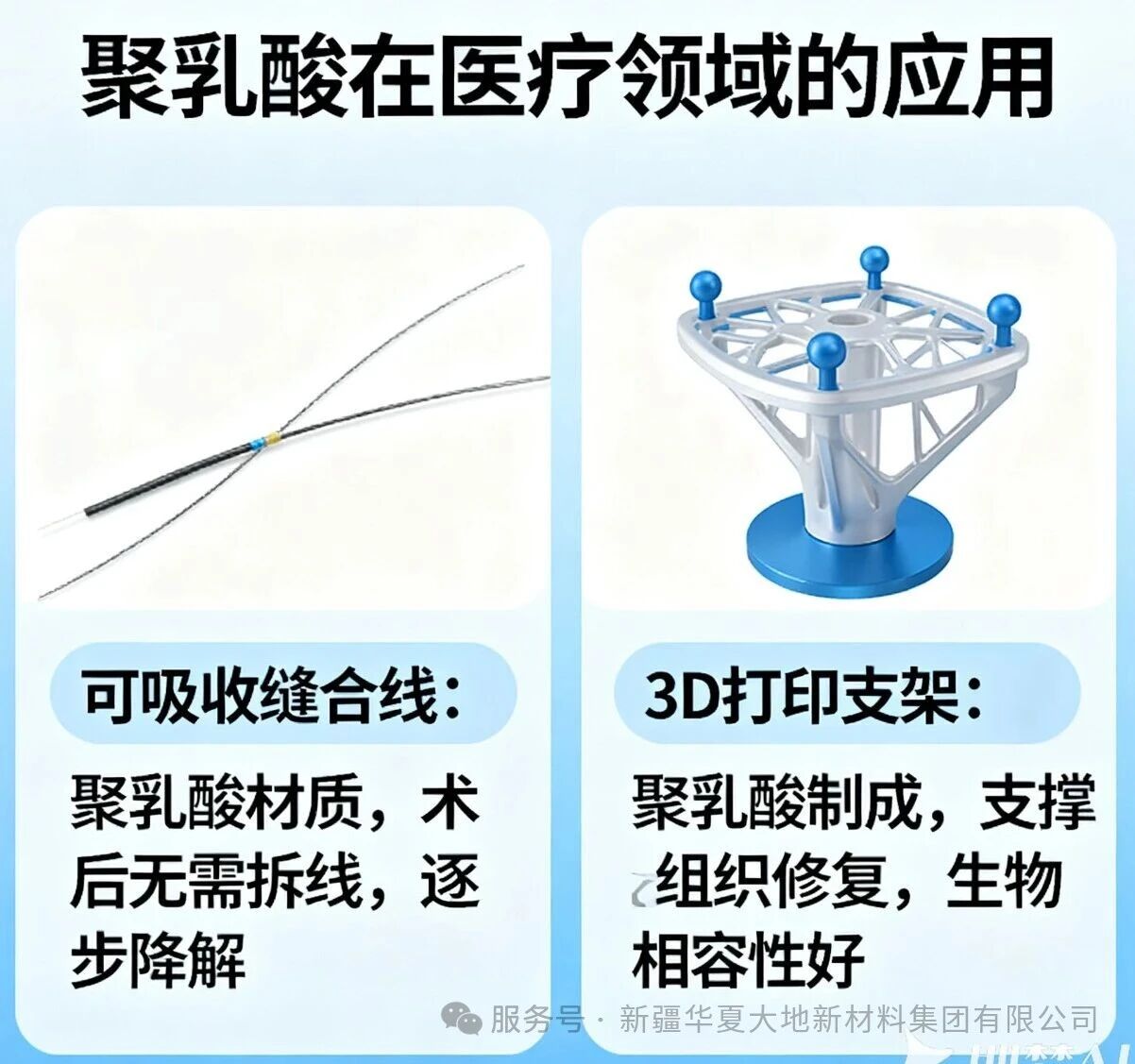

2. Medical field: Absorbable sutures and 3D printed stents

Technical Advantage: The biocompatibility and degradability of PLA make it a "star" among medical materials.

Case: The PLA suture will naturally degrade within 6 to 12 months after the operation, eliminating the need for a second surgery.

3. Electronics and Automobiles: Lightweighting and Sustainable Design

Application scenarios: Electronic device casings, automotive interior components, etc.

Trend: PLA is blended and modified with PET and PBAT to enhance its heat resistance and impact resistance.

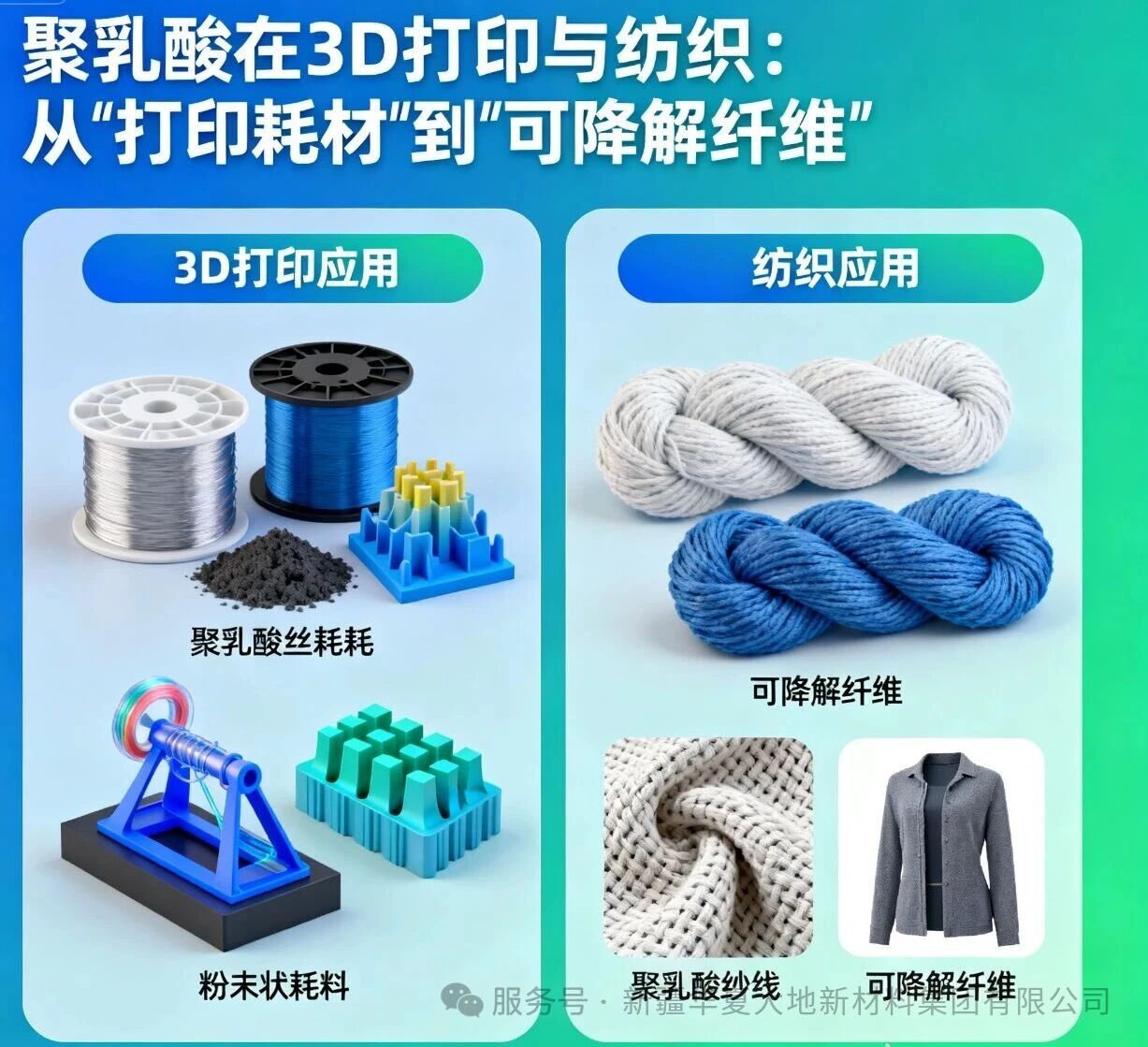

4. 3D Printing and Textile: From "Printing Materials" to "Biodegradable Fibers"

Innovation direction: PLA fibers are used in clothing and non-woven fabrics, promoting the green transformation of the fashion industry.

The "pain points" and "future" of the industrial chain

Current Challenges

The bottleneck of caprolactone: tight supply of caprolactone, technical barriers, high costs, purity requirements, and imbalance in market supply and demand.

Cost pressure: Fluctuations in raw material prices (such as corn prices) and the complexity of the synthesis process result in PLA having a higher cost than traditional plastics.

Performance limitations: The low heat resistance (< 60℃) and brittleness of PLA restrict its application in certain fields.

2. Future Breakthrough Directions

Technological innovation: Breakthrough in the domestic production technology of caprolactone (such as the strategies of JinDan Technology, FengYuan Biology, and Haizheng Biology).

Diversification of raw materials: Exploring non-food biomass raw materials such as straw and algae to reduce reliance on corn.

Policy-driven: Global "plastic ban" and carbon neutrality goals are accelerating the process of replacing plastic with PLA.

Enhancement of environmental awareness: Consumers' growing concern for recyclability, green packaging and sustainability has prompted brand manufacturers to shift to bio-based materials such as PLA.

The Green Closed Loop Future

The industrial chain of PLA represents a green closed-loop revolution from "the field" to "the end user". It not only turns corn into environmentally friendly materials, but also opens up new possibilities for the symbiotic relationship between humans and the Earth. In the future, with technological breakthroughs and policy promotion, each link of this industrial chain will become more closely integrated, and the story of PLA will shift from "replacement" to "leadership".