The core picture of research on biodegradable polymer materials

The core picture of research on biodegradable polymer materials

1 Material System and Synthesis Foundation

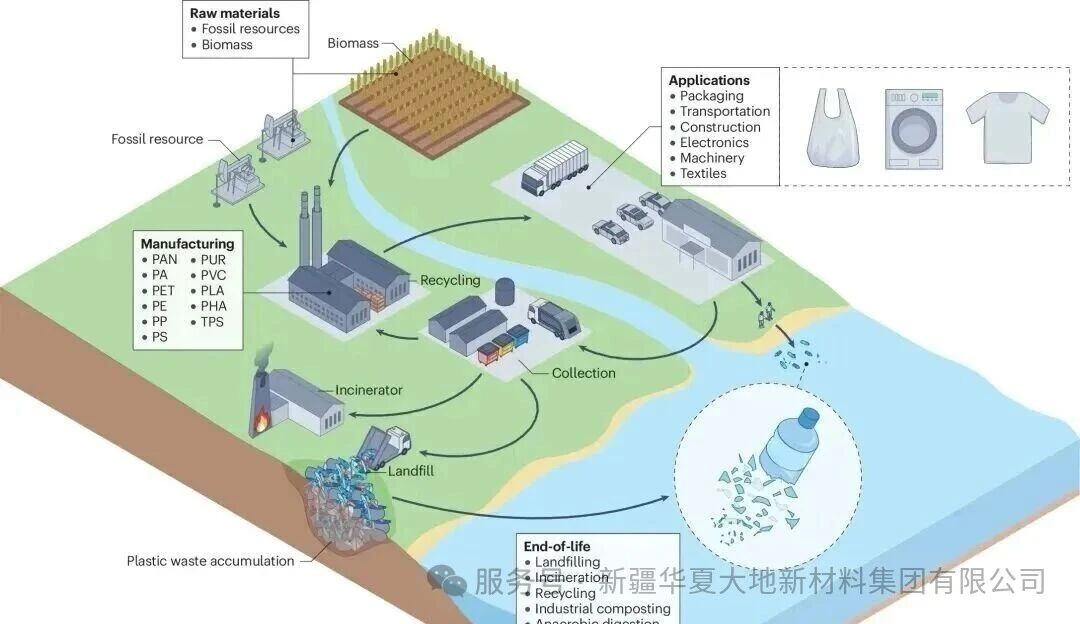

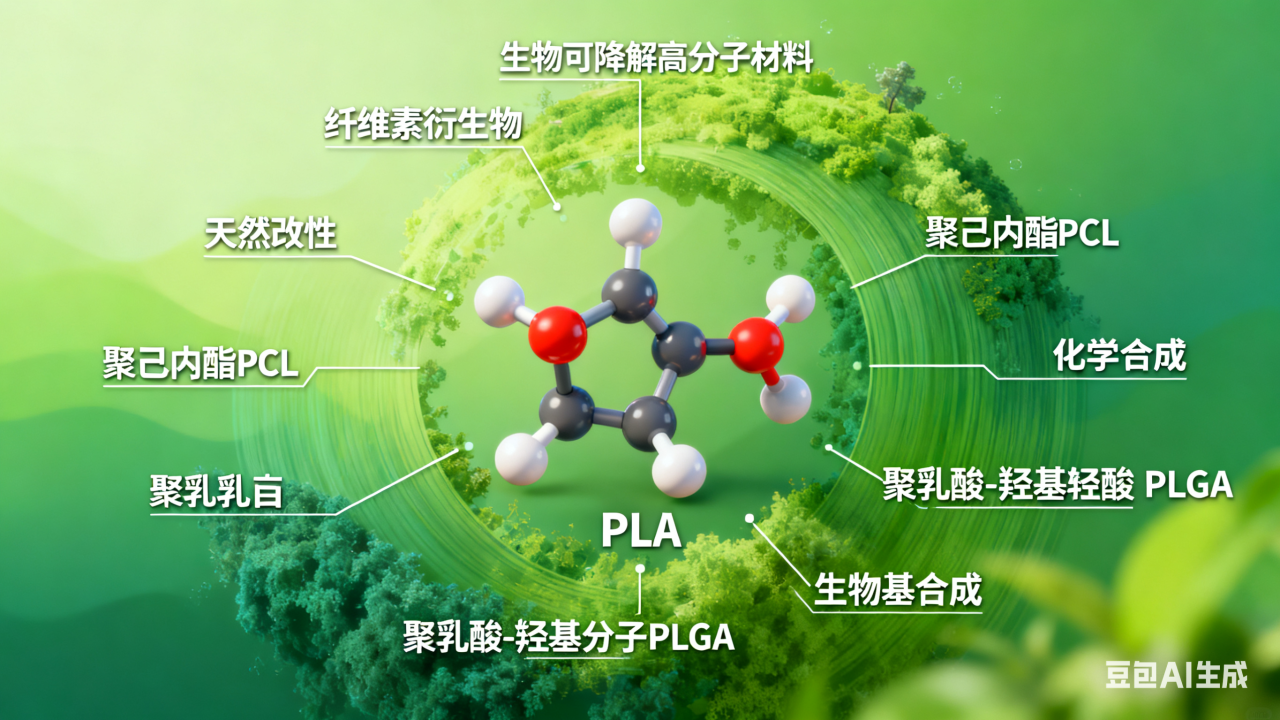

Biodegradable polymer materials are a new type of material that can gradually decompose into harmless small molecules in the natural environment or within living organisms. They can be classified into three categories based on their sources and synthesis pathways: modified natural polymers (such as cellulose derivatives), chemical synthesis materials (such as polybutylene succinate PCL, polybutylene adipate PBAT), and biobased synthesis materials (such as polylactic acid PLA, polylactic acid - glycolic acid PLGA). Among them, polylactic acid (PLA) has become the focus of research due to its origin from renewable plant resources and its final degradation products being carbon dioxide and water.

2 Performance regulation mechanism and degradation characteristics

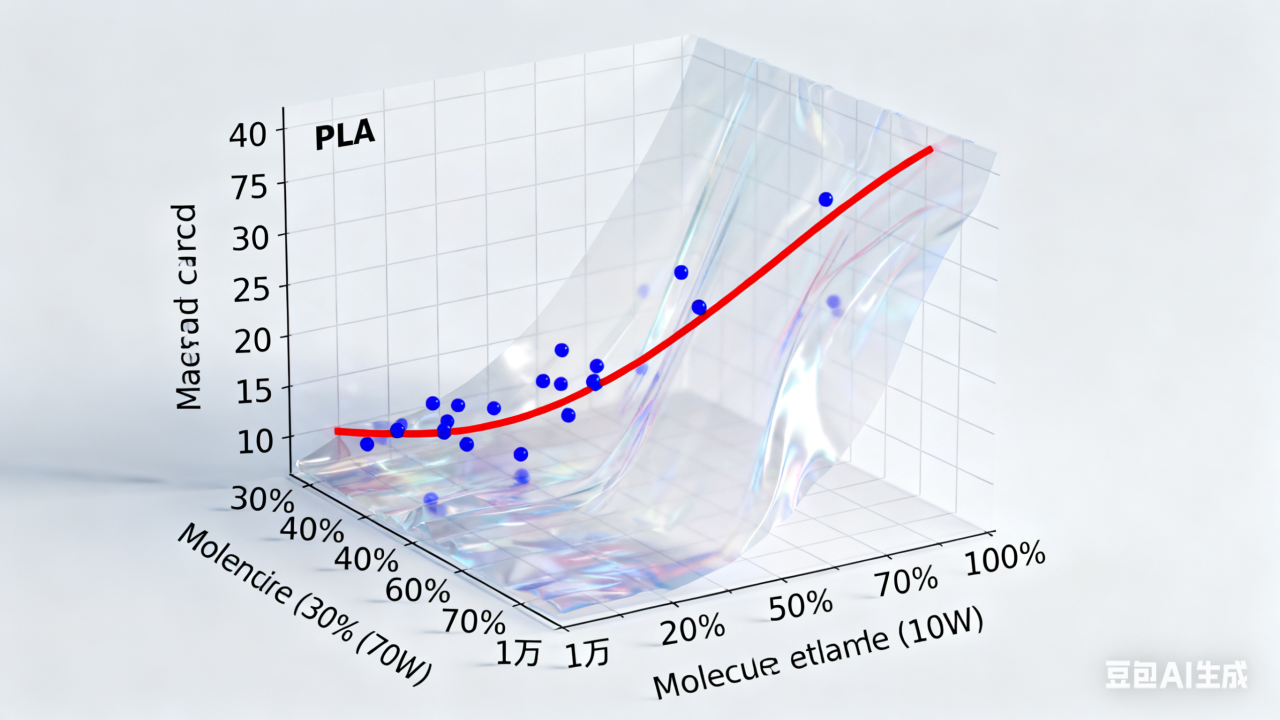

The structural properties of the material directly determine its degradation performance and application value. Molecular weight, crystallinity and crosslinking density are the core regulatory parameters: PLA with a molecular weight ranging from 10,000 to 100,000 has the most ideal degradation rate in soil, maintaining mechanical properties while being easily decomposed; when the crystallinity increases from 30% to 70%, the degradation period of PLA will extend from 10 months to 40 months, and introducing amorphous regions through copolymerization can accelerate degradation; the crosslinking density needs to be precisely balanced; too high will form a difficult-to-degrade network, and too low will result in insufficient mechanical properties.

3 Application scenarios and technological breakthroughs

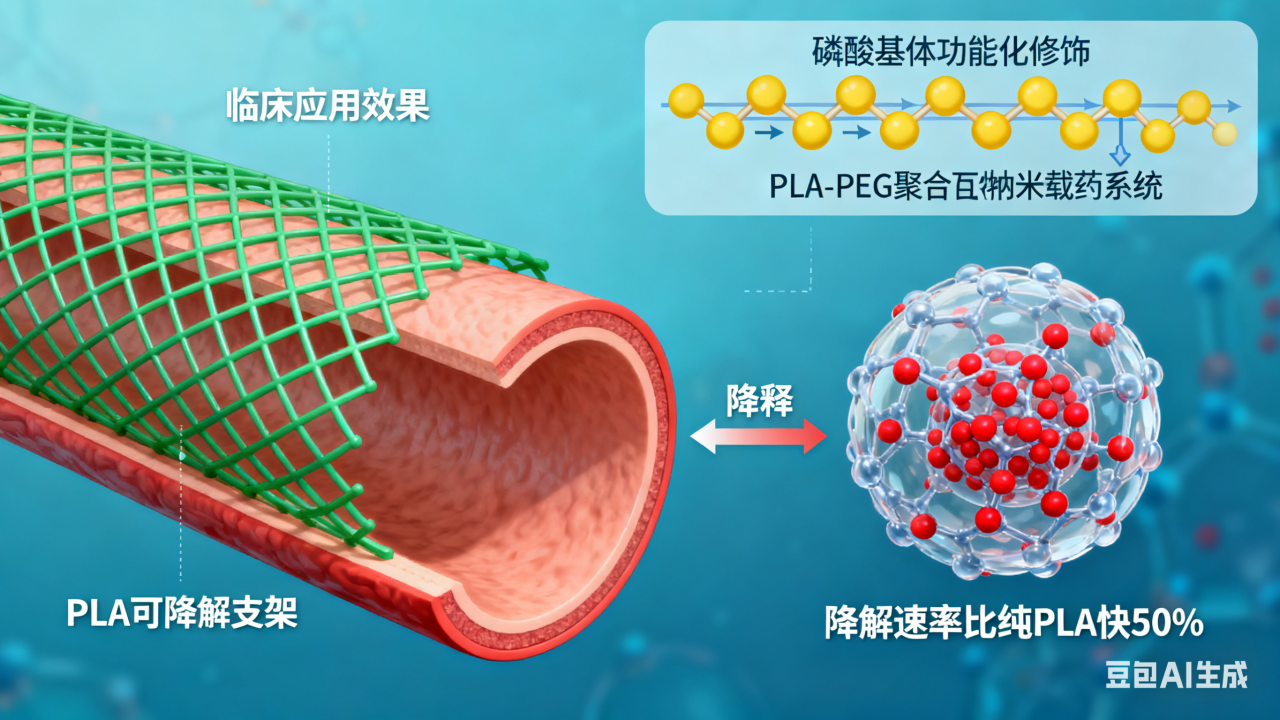

In the field of packaging, the PLA composite materials modified with cellulose nanocrystals (CNCs) have seen an increase of 50% in tensile strength and 40% in bending strength, effectively expanding their application in food packaging. The biomedical field is the advanced application scenario for PLA. The PLA biodegradable heart stent developed in the United States has shown excellent clinical results. The PLA-PEG copolymer, due to its degradation rate being 50% faster than pure PLA, performs better than traditional polymers in drug carriers. After introducing phosphate groups, its biomedical application effect has further improved.

II. Achievements, Challenges and Development Directions

1 The core value of the research breakthrough

The research on biodegradable polymer materials provides a key solution to the problem of traditional plastic pollution. Its core value lies in the dual breakthroughs of "environmental friendliness" and "performance adaptation". The zero-pollution characteristics throughout the entire life cycle of materials such as PLA from raw material preparation to final degradation are in line with the requirements of sustainable development; and through process optimization and composite modification, the improvement of material mechanical properties and degradation controllability has broken the conventional perception that "environmental-friendly materials have insufficient performance". For example, the CNCs modification technology achieves a balance between strength and degradation performance, and the ring-opening polymerization process solves the problem of preparing high molecular weight polymers, laying the foundation for industrial application.

2 The main bottleneck of the current development

Despite significant progress in research, industrial application still faces three core challenges. Cost control is the primary issue: PLA synthesis relies on lactic acid as the raw material, and the ring-opening polymerization process is lengthy, resulting in its price being much higher than that of traditional plastics, which limits its popularization in common fields such as packaging. The performance shortcomings have not yet been fully overcome. The inherent hydrophobicity, brittleness, and low heat deformation temperature (only 54℃ at a 0.46MPa load) of PLA need to be optimized through continuous modification; the precise regulation of degradation cycle is difficult, as the degradation rate of the same material varies significantly in different environments, affecting the reliability of practical application.

3 Key directions for future research

In response to the existing bottlenecks, future research should focus on achieving a full-chain breakthrough of "efficient synthesis - precise modification - scenario adaptation". At the synthesis technology level, it is necessary to develop a low-cost process for preparing high-molecular-weight PLA, such as optimizing the dehydration system in direct polymerization and exploring the opening-ring polymerization path without metal catalysts to reduce raw material and process costs. The modification research should be upgraded to "multifunctional composite", combining nanocomposite, blending modification and other methods, and simultaneously improving the mechanical properties, hydrophilicity and degradation controllability of the materials. For example, the degradation rate can be customized by adjusting the addition amount of CNCs.