Abstract

Biological manufacturing, as an important technological path for achieving green, low-carbon and sustainable development, is accelerating its evolution along the entire industrial chain of "raw materials - technology - process - product". Firstly, from the perspective of raw materials, the limitations of traditional grain-based raw materials were analyzed. The focus was on the expansion of bio-manufacturing raw materials to non-grain biomass, the development of high-performance strains and enzymes towards precision and intelligence, and the latest progress in process engineering technology and core equipment, which are evolving towards modularization and intelligence. This provides support for building a safe and stable foundation for bio-manufacturing raw materials. On the technical side, the underlying tools such as gene editing, metabolic engineering, computational design, and artificial intelligence (AI) were systematically reviewed in the precise design of core strains, chassis cells, and industrial enzymes, promoting bio-manufacturing to become more efficient, modular, and intelligent. In the process side, the key technologies such as intelligent cell factories, precise biological fermentation, online monitoring, digital twins, and the domestication of intelligent equipment were discussed in terms of their integrated innovation, accelerating the transition from experience-driven to model-driven and intelligent decision-making. In the product side, the industrialization progress and application prospects of bio-manufacturing in the fields of medicine, food, chemicals, and materials were summarized. Finally, in response to the shortcomings of China's bio-manufacturing in terms of independent control of strains and reliance on high-end equipment, key technology research and development directions were proposed, providing references for the future technical routes and industrial development of bio-manufacturing.

Biomanufacturing refers to a new industrial production model that utilizes biological systems or their components, through methods such as raw material substitution, innovation in production processes, or development of new products, to achieve low-cost, large-scale, and sustainable production in fields such as energy, chemicals, materials, medicine, and food. With the rapid development of underlying technologies such as synthetic biology, artificial intelligence (AI), and computational design, the future of biomanufacturing is accelerating its transition from traditional fermentation-driven to a disruptive manufacturing paradigm driven by intelligence and biological design. This transformation is not only an important support for the construction of manufacturing powerhouses and the enhancement of industrial chain competitiveness, but also an important measure for promoting new industrialization, economic high-quality development, and the cultivation of future industries.

Under the impetus of the new round of global technological revolution and industrial transformation, biomanufacturing, as the core direction where biotechnology and advanced manufacturing are deeply integrated, bears the historical mission of promoting the green transformation of the manufacturing industry. Currently, in many product manufacturing methods that are crucial to the national economic development, China still largely relies on traditional preparation methods such as petrochemicals, organic synthesis, and plant extraction, which have structural bottlenecks such as strong resource dependence, high carbon emissions, and slow technological iteration. Biomanufacturing, with its advantages of renewable raw materials, green processes, and product designability, can cover multiple key fields of the national economy such as energy, chemicals, food, and medicine, and has become the core handle to solve the structural contradictions of traditional manufacturing, such as high resource dependence, high carbon emission intensity, and slow technological iteration.

In recent years, the state has explicitly incorporated biomanufacturing into its future strategic framework. In the 2024 government work report, it was proposed to "actively create new growth engines such as biomanufacturing, commercial aerospace, and low-altitude economy", and in 2025, it was again emphasized that "cultivate biomanufacturing, quantum technology, embodied intelligence, and 6G, etc., as future industries", marking that China's biomanufacturing development has entered a new stage of national strategy. Driven by the "carbon neutrality" goal, its strategic value in green and low-carbon transformation, resource structure optimization, and industrial chain reconfiguration will be further highlighted.

Based on this, this paper, from the perspective of the entire industrial chain covering raw materials, underlying technologies, process intelligence, and product systems, systematically analyzes the key technological progress, bottleneck challenges, and future development paths of China's biomanufacturing, providing references for technological breakthroughs and strategic planning in China's biomanufacturing.

1. Key Technological Trends in Biomanufacturing

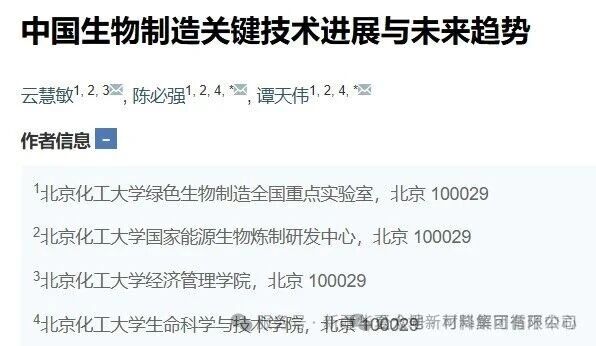

Biomanufacturing is a sustainable production model that utilizes biotechnology and biological processes, using microorganisms, enzymes, plant or animal cells as production platforms to manufacture various chemicals, materials, and energy products. The core industrial chain of biomanufacturing includes raw material supply, production platforms (strains and enzymes), equipment, processes and techniques, product management and waste disposal, etc. (Figure 1). At the method level, it encompasses experiments, computational models, and intelligent technologies, forming a multi-dimensional and comprehensive technical system. Its application fields cover energy, chemicals, materials, food, agriculture, medicine, cosmetics, and many other industries, and it is constantly expanding and deepening.

Figure 1 Framework of the Biomanufacturing Industry Chain

Biomanufacturing, as an emerging industrial production model, has undergone multiple innovations from basic research to technological application. In the early stage, biomanufacturing mainly relied on traditional microbial fermentation technology to produce basic chemicals and biological products, such as antibiotics, enzyme preparations, and amino acids. With the continuous breakthroughs in biotechnology, especially the development of genetic engineering and synthetic biology, biomanufacturing has gradually entered the era of high precision and high efficiency. In recent years, breakthroughs have been continuously achieved in the research and development of underlying technologies and key core technologies of biomanufacturing. The speed of new product development and the green environmental protection level of process and technology have been significantly improved. Emerging industries have rapidly emerged, and the application fields have also been continuously deepening and expanding. The following briefly introduces the integration and development situation of some key technologies in the biomanufacturing industry chain.

1.1 Expansion of Bio-Manufacturing Raw Materials to Non-Food Biomass

Traditional bio-manufacturing mainly relies on fermentable sugar-based raw materials (such as glucose and sucrose from food crops like corn and sugar cane), providing essential carbon sources and energy for microbial metabolism. With continuous breakthroughs in efficient utilization technologies of lignocellulose and one-carbon compounds, the raw material system of bio-manufacturing is gradually expanding from "food dependency" to more diversified non-food biomass. These new raw materials not only effectively alleviate the high dependence of bio-manufacturing on edible sugar-based raw materials, but also help reduce competition with food production in terms of land and resources.

What is particularly worth noting is that one-carbon compounds, such as carbon dioxide (CO₂), carbon monoxide (CO), formic acid (CH₂O₂), and methanol (CH₄O), are becoming important candidate raw materials for the next generation of biomanufacturing. By converting one-carbon molecules into multi-carbon chemicals through microbial or biocatalytic systems, not only can the raw material structure be optimized, but also the diversity of resource utilization and the sustainability of the manufacturing process can be significantly enhanced. At the same time, by-products from petrochemical and coal chemical processes, such as various organic acids like formic acid, methanol, acetic acid, propionic acid, and butyric acid, are also regarded as important raw materials for the next generation of biomanufacturing. These by-products can be used to synthesize biopolymers and a variety of small molecule compounds, further expanding the range of available carbon sources.

In terms of specific technical implementation, the engineered bacterial strains developed by the American company Ginkgo Bioworks have been able to efficiently convert the hydrolysis products of lignocellulose into rare sugars, with a yield increase of over 40%. Novozymes has designed and developed new cellulase and yeast strains that can convert cellulose into ethanol at a rate of 92%. For every 1 ton of cellulose ethanol produced, 3.5 tons of carbon dioxide emissions can be reduced, providing strong support for low-carbon bio-manufacturing. More advanced platforms such as the gas fermentation technology of LanzaTech can directly convert one-carbon gases into sustainable chemicals like ethanol, creating a new model of "negative carbon production" and providing a new solution for low-carbon green manufacturing.

1.2 The development of high-performance microorganisms and enzymes is evolving towards precision and intelligence.

In the biological manufacturing system, microbial strains act as the "biological factories" responsible for converting raw materials and synthesizing products, while enzymes serve as the "biological catalysts" that accelerate and regulate metabolic reactions. Through the metabolic pathways of the microorganisms and the catalytic action of the enzymes, microorganisms can efficiently convert various carbon sources into target products such as drugs, chemicals, and biological materials. Therefore, the development of high-performance microorganisms and efficient enzyme systems is a core factor for enhancing the production efficiency, reducing production costs, and optimizing product quality in biological manufacturing.

Traditional biotechnology mainly relies on experimental research, data analysis and model assistance, and uses physical, chemical and biological methods to modify biological processes. Although significant progress has been made in fields such as genetic engineering, fermentation processes, cell culture and pharmaceutical research, there are still significant limitations in handling massive and complex data, predicting unknown outcomes and optimizing experimental procedures, making it difficult to meet the high requirements for efficiency and accuracy of modern biomanufacturing.

With the continuous breakthroughs in gene editing technology, especially the widespread application of clustered regularly interspaced short palindromic repeats (CRISPR) technology, the precise regulation and system reconstruction of microbial metabolic pathways have entered a stage of rapid development. The CRISPR series of tools have enabled precise and programmable modifications of the genome, providing strong support for enzyme molecular engineering, chassis cell reconstruction, and the design of complex regulatory networks. As a result, biomanufacturing has moved from traditional empirical modification to a new era of mechanism-driven precise metabolic engineering, making the vision of "designing cells on demand" gradually a reality.

Meanwhile, significant progress has been made in the development of non-model and extreme microbial chassis. Microorganisms adapted to extreme environments, such as halophilic bacteria, thermophilic bacteria, and acid-base-tolerant bacteria, demonstrate great potential as "next-generation cell factories". They not only have higher tolerance and broader substrate adaptability, but also can support more complex and efficient biosynthetic pathways. In terms of the construction of standardized cell factories, the United States and the European Union, among others, have successively formulated major strategic plans such as "Life Foundry" and "Microbial Cell Factory", promoting the resourceization, modularization, and engineeringization of chassis cell resources. In addition, major international biotechnology companies are also continuously strengthening the construction of industrial strain research and development platforms, by creating core strains to enhance market competitiveness.

As precision technologies rapidly evolve, AI is becoming a key driving force in advancing the intelligence of strain and enzyme design. Based on the "AI for Science" paradigm, AI tools such as AlphaFold and RFdiffusion have significantly enhanced processes like protein structure prediction, enzyme active site optimization, and mutant design, greatly improving the efficiency of enzyme molecular engineering and microbial metabolic optimization. By integrating multi-omics data and building interpretable metabolic network models, AI can now assist in establishing more accurate cellular metabolic maps, enabling the identification of metabolic bottlenecks, pathway optimization, and the automatic generation of strategies. Thus, strain development is shifting from the traditional "trial-and-error optimization model" to a new era driven by mechanisms, data-driven, intelligent decision-making, and customized synthesis, laying a solid technical foundation for precise and intelligent biomanufacturing.

The industry and academia are building AI-based full-process automated platforms. Typical examples include: The intelligent engineering platform developed by the University of Illinois in the United States, which integrates AI design - construction - testing - learning, and has been applied to the biomanufacturing of lycopene; Ginkgo Bioworks has achieved comprehensive automation and high scalability in gene design, synthesis, introduction, target cell screening, and cultivation condition optimization through the introduction of AI and automated robotic technology, promoting the industrialization of genetic engineering. Similar research platforms such as liquid handling robots, automated cloning screening systems, and standardized cultivation and detection systems are constantly emerging, significantly improving the efficiency of microbial and functional component research and development.

At the strategic level, the US government has designated the integration of AI and biotechnology as a national strategic priority. In 2022, the US president signed the "National Biotechnology and Biomanufacturing Plan", which will sequence the genomes of 1 million microbial species over the next five years and systematically analyze the functions of at least 80% of the newly discovered genes. It is expected that in the next 20 years, the discovery and application of new genes, metabolism and functions will be significantly accelerated. This strategy not only promotes the intelligent upgrading of biomanufacturing but also provides policy and technical examples for biotechnological innovation. Through this cross-segment intelligent empowerment, AI is driving biomanufacturing from laboratory exploration to large-scale, intelligent and precise development, providing new impetus for industrial upgrading and sustainable development.

1.3 Process engineering technology and core equipment undergo iterative transformation towards modularization and intelligence

In the industrialization process of traditional biological manufacturing, there are numerous bottlenecks, such as insufficient flexibility of equipment, limitations in process scaling, and fragmentation of cross-scale production data. These issues severely restrict the efficiency of product transformation. To address these problems, the process engineering of biological manufacturing is evolving towards modular and intelligent system integration. Through the two-way innovation of bottom-level process reconfiguration and top-level system integration, the design concept of equipment and the production paradigm are upgraded, achieving seamless connection from the laboratory to industrial production.

The modular design achieves "plug-and-play" flexible assembly through decoupling of standardized functional modules such as bioreactors and separation purification units. This significantly enhances the flexibility and scalability of the process. For instance, the Ambr® modular micro-bioreactor array launched by Sartorius can support parallel condition screening and process optimization, greatly accelerating the regulation of production parameters. At the same time, the integrated AI algorithms can monitor and adjust key parameters such as dissolved oxygen and pH in real time, improving cell culture efficiency and enhancing the stability and controllability of the production process.

Furthermore, the construction of the virtual reactor model makes it possible to conduct pre-verification of the process, predict faults, and perform dynamic optimization, thereby enhancing the accuracy and reliability of the production process. In the manufacturing process, the introduction of personalized and precise technologies such as additive manufacturing has made the biomimetic manufacturing of complex tissues and organs a reality. In the future, with the advancement of technology, the current limit of single-molecule detection will be broken, and through interdisciplinary collaboration, the technology will be pushed towards higher throughput and higher precision.

Furthermore, the development, separation efficiency and selectivity improvement of materials in response to environmental stimuli will become the key research direction in the future. The big data platform built based on the industrial Internet of Things will provide important support for the optimization of the mechanism-data hybrid model, promoting the continuous innovation and efficiency improvement of the separation process.

2 Core Technical Issues and Challenges in China's Biomanufacturing

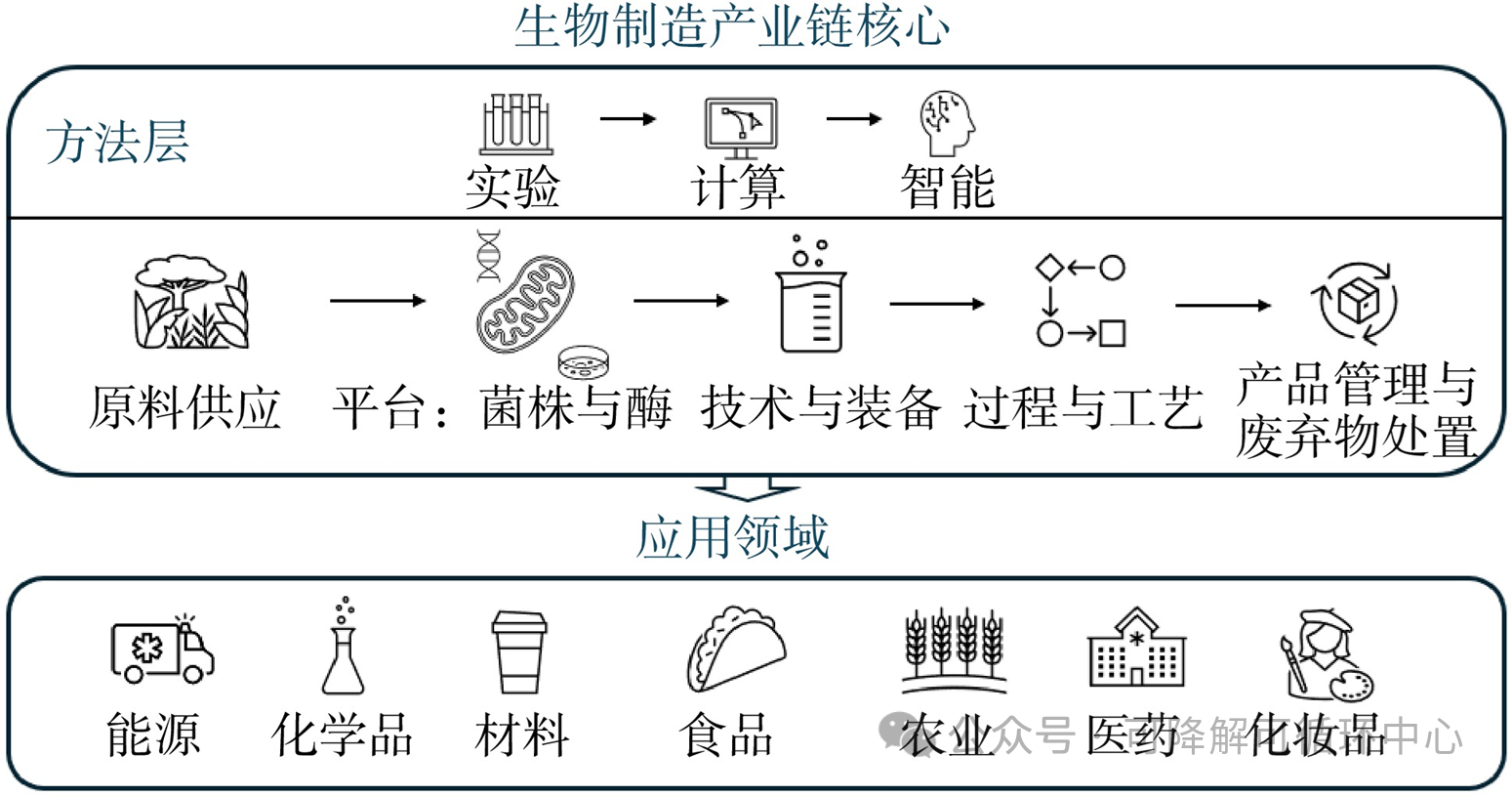

After the overall planning by the state in the early stage, China's overall strength in biomanufacturing has approached the international advanced level, and some fields have achieved leadership. However, compared with developed countries and regions such as the United States and Europe, China still faces a series of technical and industrial challenges in the field of biomanufacturing. The following briefly elaborates several key technical issues at different stages of the industrial chain (Figure 2).

Figure 2 Key technical issues and challenges in the biomanufacturing industry chain

2.1 Technical Bottlenecks in Resource Utilization and Raw Material Substitution

At present, the Chinese bio-manufacturing industry mainly relies on food resources such as starch-based substances, with approximately 90% of the primary raw materials coming from cereal crops like corn. For instance, approximately 1.9 t of grain raw materials are consumed for every 1 t of citric acid produced. In key areas such as bio-based plastics and bio-based chemical fibers, the reliance on cereal crops is also significant. This "using food to produce materials" model not only exacerbates the resource contradiction of "competing with the people for food and competing with livestock for feed", but also weakens the security and autonomy of the industrial raw material supply, becoming a major obstacle hindering the sustainable development of bio-manufacturing.

In contrast, China has an extremely abundant non-food biomass resource, with an annual output exceeding 3.5 billion tons, covering various types such as crop residues, forestry waste, and organic household garbage. It has great potential as a resource. However, there are still significant challenges in the utilization of non-food biomass, including high costs of collection, storage, and logistics, low saccharification efficiency, high costs of enzyme preparations, and poor batch stability of materials. These technical and economic bottlenecks have not yet enabled the realization of large-scale and high-value utilization. Therefore, building a diversified and non-food-based raw material system has become a key breakthrough point for promoting high-quality development of bio-manufacturing and breaking through resource constraints.

2.2 The issue of independent control over core bacterial strains

China still has significant shortcomings in its ability to independently control microbial strain resources. The high dependence on key industrial strains and enzyme preparations has become a major bottleneck restricting the high-quality development of the bio-manufacturing industry. Currently, over 80% of industrial strains rely on imports, especially in several fields with international competitiveness, where China's dependence on imports is relatively high. For instance, in 2024, China's supply of feed amino acids was approximately 4.89 million tons, increasing by 12.9% and accounting for 70% of the global total. However, the proportion of domestic chassis bacterial strains was less than 20%. Moreover, over 80% of the enzyme preparations required in the fermentation industry rely on imports, especially in high-end enzyme preparation fields such as food enzymes and industrial washing enzymes, where foreign brands have nearly achieved a monopoly.

With the intensification of the Sino-US trade friction, especially the restrictions imposed by the US on Chinese researchers accessing sensitive biomedical data starting from April 4, 2025, China's passive situation in the field of biological resources has become more evident, further highlighting the urgency of achieving independent control over core resources. Therefore, enhancing the autonomous control ability of microbial resources has become the top priority for safeguarding national biological security and promoting the high-quality development of the biomanufacturing industry.

2.3 Design of Biocatalysts and Weaknesses in Underlying Technologies

China started relatively late in the field of intelligent design of biocatalysts and still has a significant gap compared to international advanced levels. Currently, leading international institutions have established systematic technical barriers in key technologies such as algorithm accuracy for enzyme function prediction, structural-function correlation modeling, data resource accumulation, and de-annotation prediction. However, in core technologies such as enzyme design and molecular docking, China still heavily relies on algorithms and platforms developed abroad, such as AlphaFold, RoseTTAFold, and AutoDock, and the autonomy of key technologies urgently needs to be broken through.

In terms of strain construction, China generally optimizes strains by knocking out or overexpressing individual genes in the synthetic pathway. However, this method is time-consuming and inefficient, making it difficult to meet the demand for rapid construction of high-performance industrial strains. In contrast, leading international enterprises have deeply integrated gene editing technology with AI algorithms, achieving high precision, high stability, and commercial maturity in the strain construction process. In comparison, China is still in the catching-up stage in terms of basic algorithms and software development for strain design, as well as in optimizing high-performance chassis cells, evaluating the performance of gene elements, and fine-tuning expression regulation. It urgently needs to accelerate the establishment of an independent engineering strain system platform to promote technology integration and independent innovation.

2.4 Insufficiency of High-End Equipment and Intelligent Manufacturing Capabilities

There are significant shortcomings in equipment and automation systems in China's biomanufacturing sector. Particularly, the dependence on foreign products for high-end research instruments and key production equipment is high, which has become a key factor restricting independent innovation and industrial security. At the production application level, the intelligent manufacturing, standardized processing, online detection, and intelligent control of equipment have not yet formed a complete system. Core equipment such as high-end bioreactors, efficient separation media, and high-precision instruments still rely heavily on imports. European and American countries restrict this through measures such as technology export control and patent barriers. If domestic substitution and breakthroughs in underlying technologies cannot be achieved, the industrial upgrading will face a long-term "choking" risk.

In the research and development of automated integrated systems, China is also lagging behind. Especially in high-end control systems (such as industrial software and programmable logic controllers), 95% of the market share is monopolized by foreign manufacturers. At the same time, the basic technologies required for intelligent manufacturing, such as precise sensing technology and intelligent control algorithms, are mostly imported, further weakening the autonomy and controllability of the production process. These technical bottlenecks severely restrict the autonomy of equipment systems and the intelligent upgrading of the production process. Therefore, building a high-end equipment system with independent intellectual property rights, developing intelligent, standardized and controllable manufacturing platforms, is the key support for promoting the leapfrog development of China's biomanufacturing.

3 Key Technical Development Directions and Key Tasks for China's Bio-manufacturing in the Future

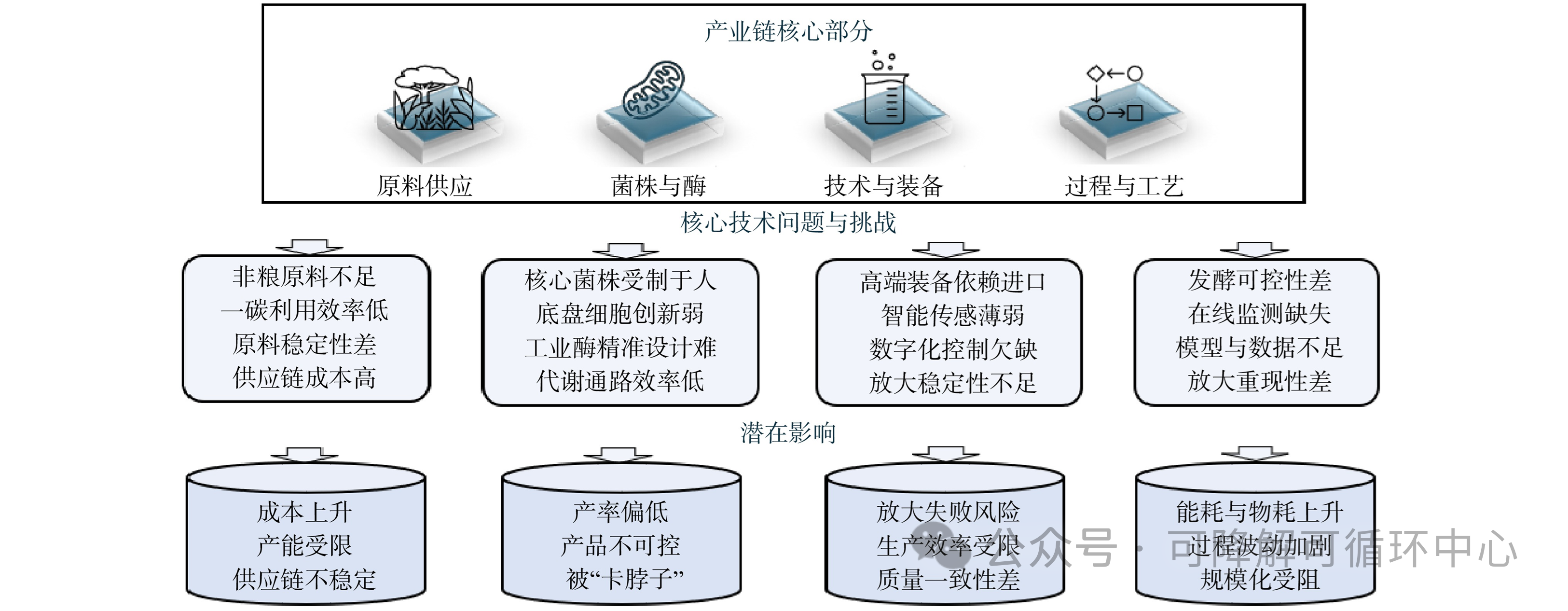

To achieve the large-scale, intelligent and green development of bio-manufacturing, it is urgent to conduct systematic technological research focusing on the core links of the entire industrial chain. The technological breakthroughs in future bio-manufacturing will mainly concentrate on four directions: raw material supply, cell engineering, equipment system and process control, and terminal product expansion. Around these key links, it is necessary to build a green raw material system based on non-food resources and one-carbon raw materials, promote intelligent design and precise regulation of enzymes and strains, create efficient and intelligent equipment and process platforms, and accelerate the expansion of product systems in multiple fields. The following will systematically elaborate on the key technical development directions and core tasks of future bio-manufacturing from the aspects of raw material end, cell engineering, equipment process and product application (Figure 3).

Figure 3 Key Development Directions and Key Tasks of Biomanufacturing Technologies

3.1 Raw Material End: Develop technologies for converting one-carbon raw materials and utilizing non-food resources

For low-cost renewable carbon resources such as carbon dioxide, carbon monoxide, and methane, as well as abundant non-food biomass resources such as crop residues, forestry waste, and lignocellulose, future efforts should focus on developing efficient raw material conversion technologies. The specific tasks are as follows.

1) Efficient conversion of one-carbon raw materials. Develop carbon dioxide conversion technologies driven by renewable energy to achieve the efficient production of low-carbon and fermentable raw materials such as methanol, formic acid, and acetic acid from carbon dioxide. Secondly, construct biological synthesis pathways for target products such as amino acids, organic acids, chemical alcohols, organic amines, and hydrocarbon chemicals from one-carbon raw materials. Develop new fermentation technologies and chemical/multienzyme cascade catalytic systems that can efficiently utilize one-carbon raw materials, and break through the biotechnological conversion technology from one-carbon raw materials to target products.

2) Utilization of non-food biomass resources. Make full use of China's abundant non-food biomass resources, such as crop straw, forestry waste, and lignocellulose. Develop efficient saccharification, enzymatic hydrolysis, and fermentation technologies to achieve high conversion rates and high value utilization of raw materials. Construct an intelligent biological utilization route for wood-based cellulose raw materials, including the development of customized enzyme preparation systems and high-performance chassis strains, to achieve efficient conversion from raw materials to target chemicals.

3) Intelligent and engineering application. Establish an efficient artificial biological utilization pathway for one-carbon raw materials and non-food resources, and build an intelligent biological fermentation and catalytic technology platform. Complete the industrial-scale verification and full life-cycle assessment of the conversion of one-carbon raw materials and non-food resources into chemical products, and promote large-scale production demonstrations and widespread application.

Through these technological breakthroughs, a biological manufacturing raw material system based on one-carbon compounds and non-food biomass can be established, laying the foundation for a low-carbon, efficient and sustainable chemical industry.

3.2 Intelligent Design and Creation of Cell Engineering

In the biological manufacturing system, enzymes and microorganisms are the core driving factors of biological manufacturing. Therefore, one of the key focuses of future biological manufacturing is to develop precise mining and intelligent design technologies for industrial enzymes and microorganisms. The specific development directions are as follows.

Intelligent development of industrial enzymes.

In-depth analysis of the catalytic mechanisms and structure-activity regulation principles of key enzyme types, combined with AI models and big data analysis, precisely discovers enzyme gene resources with novel functions, unique sequences and high biological activity. At the same time, developing new bioreaction units and utilizing enzyme catalytic reactions to replace reactions that are difficult to synthesize by traditional chemistry will provide more green and efficient solutions for bio-manufacturing. Additionally, it is necessary to develop highly adaptable immobilization materials and technologies to achieve low-cost large-scale production of high-performance immobilized enzyme preparations, thereby expanding their applications in multiple fields such as energy, chemical engineering, medicine, light industry and food. Finally, a technology system for intelligent industrial enzyme development based on AI-driven technology should be constructed, developing large software platforms covering enzyme design, screening, optimization and other functions, establishing an independent and controllable core database and algorithms, and achieving precise mining of enzyme information and rapid innovation of performance improvement methods. Through this transformation, the development of industrial enzymes will transition from the traditional "experience-driven" model to the "computational-driven" paradigm, promoting the intelligence and green low-carbon transformation of bio-manufacturing.

2) Intelligent cell factories and precise biological fermentation.

In the future, the key technological breakthroughs in biomanufacturing will focus on the development of intelligent cell factories, precise biological fermentation, and intelligent equipment. Therefore, basic open-source tools and algorithms based on rules, data-driven and AI methods should be developed, aiming at AI modeling of cells, to provide guidance for the design and optimization of cell factories. This will significantly improve their performance and output in industrial production. Secondly, an extreme microbial resource library should be constructed, and efficient gene editing technologies should be developed to significantly enhance the manufacturing capabilities of non-model microbial cell factories. At the same time, AI analysis of large-scale biological data should be utilized, and digital twin and its combination with knowledge graphs, etc., should be employed as digital means to establish intelligent cell factory technology integrating cell metabolism and process control. Complete the algorithm, tools and software development for the digital modeling of independent innovation cell factories, and develop a complete common technical system of high-precision digital cell models, including technical specifications and standards in aspects such as data collection, processing, model construction, algorithm optimization, etc., significantly improving the efficiency and accuracy of cell factory design and optimization.

Through these technological breakthroughs, biological manufacturing will shift from the traditional experience-driven model to an intelligent and green low-carbon industrial production mode, enabling rapid development of enzymes and bacterial strains, intelligent fermentation, and efficient process optimization.

3.3 Equipment and Processes: Intelligent Cell Factories, Precise Biological Fermentation, Intelligent Equipment

In the process of biomanufacturing, the intelligent upgrading of equipment and processes is the key to promoting efficient, green, and precise production. Future development should focus on the following directions. Develop diversified intelligent sensing equipment and online detection technologies for biological processes to achieve real-time and high-precision monitoring of key parameters such as dissolved oxygen, pH value, temperature, substrate concentration, and metabolite products. Integrate big data and AI and other cutting-edge technologies to establish precise scaling-up models. Through the development of intelligent bioreactors and process enhancement technologies, build an intelligent control system for the "intelligent sensing - intelligent decision-making - intelligent regulation" of biological reaction processes. Additionally, establish a digital design platform for key supporting materials, develop highly accurate separation media (such as microspheres, crystalline materials, membrane media, etc.), and develop continuous separation processes and equipment to promote the construction of a new generation of intelligent biomanufacturing systems.

High-performance separation and materials technology.

Establish a digital design platform for key supporting materials, develop high-precision separation media, including microspheres, crystalline materials, membrane media, etc., to achieve a dual improvement in separation efficiency and selectivity. Promote the research and development of continuous separation processes and equipment, realize process integration, modularization and scalability, and provide support for large-scale production. Explore responsive materials and intelligent separation technologies, enabling the separation process to be dynamically regulated according to environmental changes or product characteristics, thereby enhancing the flexibility and stability of the process.

2) Integration of intelligent equipment and processes.

Build an intelligent and modular biological manufacturing system, integrating fermentation, separation, detection, and control processes to achieve seamless connection from laboratory to pilot production and industrial production. Combine AI and industrial Internet of Things technology to realize real-time data analysis, fault prediction, and optimization control of the production process, thereby improving production efficiency, reducing energy consumption and resource usage. Promote the deep coupling of intelligent equipment with cell factories and precise biological fermentation, providing support for the green, low-carbon, flexible, and high-quantitative characteristics of biological manufacturing.

Through the establishment of the aforementioned technical system, the future biological manufacturing equipment and processes will achieve high levels of intelligence, refinement and modularization, significantly enhancing production efficiency, product quality and sustainability, and laying the foundation for the large-scale and industrialization of the next-generation biological manufacturing industry.

3.4 Product Side: Expansion of Multi-Domain Product System Driven by Biomanufacturing

With the rapid advancement of biomanufacturing technology, its applications are accelerating their penetration from the traditional pharmaceutical field to multiple domains such as energy, chemicals, materials, food, agriculture, and environmental governance, forming a new type of product system covering the entire industrial chain. Biomanufacturing not only gives rise to emerging products such as high-energy-density biofuels, sustainable materials, environmentally friendly products, and innovative foods, but also promotes the restructuring of the industrial structure and the emergence of new business models, bringing significant economic benefits, social value, and strategic significance.

1) In the energy sector, efforts should be made to promote green and low-carbon alternatives. Key areas of focus should be on developing bio-aviation fuels and bio-hydrogen, among other renewable alternative energy sources. These products are crucial pathways for achieving deep decarbonization in industries such as aviation and transportation, and will also become an important part of the future energy system.

2) In the field of chemicals, breakthroughs should be made in biobased platform compounds. The key focus should be on overcoming the synthesis bottlenecks of biobased organic acids, polyols, amines, etc. By combining artificial metabolic pathways with modular multi-enzyme catalytic systems, the conversion efficiency of these compounds into high-molecular materials such as polyesters, polyamides, and polyurethanes should be enhanced, providing important support for the de-petrochemicalization and decarbonization of the chemical industry.

3) In the field of materials, a renewable material system should be established. At the material end, efforts should be made to vigorously develop key products such as high-performance biodegradable plastics, bio-based fibers, and composite materials, to address the balance between mechanical properties and environmental degradability, achieve functional modification and industrial scale-up, and promote the transformation of the material system from reliance on petrochemical resources to reliance on renewable resources.

4) Synthetic biology in the pharmaceutical field drives drug innovation. We should accelerate the development of synthetic biology-driven drug intermediates, active ingredients of traditional Chinese medicine, natural products, and vaccines. We should achieve systematic innovation from strain design, pathway construction to production scale-up. We should enhance efficiency and purity through high-throughput screening and computational-assisted design to strengthen the international competitiveness of China's pharmaceutical industry.

5) Food and agriculture establish a non-arable land-dependent nutrition supply system. In the fields of food and agriculture, efforts should be made to vigorously develop alternative proteins, artificial sweeteners, functional foods, and biological agricultural input products, promoting the green transformation of agriculture and ensuring food security. Taking protein as an example, China's annual demand for feed protein exceeds 40 million tons, and the annual import of soybeans exceeds 100 million tons. Due to genetic resource limitations, China's soybean yield is 58% of that of the United States, and the planting cost is 1.35 times that of the United States. To meet the demand, China's soybean planting area would need to increase by 720 million acres or increase by 4.79 times, which is difficult to achieve in the short term. Biomanufacturing can obtain high-quality microbial protein through one-carbon gas fermentation and co-production with bulk chemical fermentation, which can establish a "non-arable land-dependent" protein supply chain, making significant contributions to ensuring China's food security.

6) Environmental governance and high-end refined applications, expanding strategic emerging fields. In the area of environmental governance, efforts should be made to develop biodegradable materials and green remediation agents, providing strong support for achieving the goals of "carbon peak and carbon neutrality"; in high-end refined applications, we should focus on consumer upgrading and industrial frontiers, promoting the development of natural pigments, flavoring and fragrances, cosmetic active ingredients, and special materials for national defense and aerospace, thereby enhancing China's international discourse power in emerging and strategic industries.

Overall, the development of the product side not only affects the economic benefits and market scale of the biomanufacturing industry, but also relates to national energy security, industrial upgrading, environmental protection, and people's quality of life. By establishing a solid foundation in basic fields such as energy, chemicals, materials, and medicine, and achieving strategic expansion in emerging directions such as food agriculture, environmental governance, and high-end applications, China is expected to establish a biobased product system covering the entire industrial chain. In the future, through policy guidance, standard establishment, demonstration promotion, and international cooperation, it is necessary to accelerate the large-scale application and international development of biomanufacturing products, making it an important industrial pillar supporting green and low-carbon transformation and sustainable development.

4 Conclusion

This paper conducted an in-depth discussion on the latest advancements and future trends of biomanufacturing technology. With the continuous development of technology, biomanufacturing has gradually shifted from the traditional model of using grains as raw materials and relying on manual experiments, to a more intelligent, green, low-carbon, and non-grain resource-oriented production path. By integrating advanced technologies such as AI, gene editing, and enzyme catalysis, biomanufacturing technology not only enhances production efficiency, reduces resource consumption, but also significantly reduces the negative impact on the environment, promoting the sustainable development of the industry.

In the future, bio-manufacturing will focus on breaking through key technologies such as intelligent cell factories, precise biological fermentation, and the domestication of core equipment, to build a more efficient, stable and safe manufacturing system. The deep integration of intelligent technologies will drive bio-manufacturing to shift from being driven by experience to "computational-driven - intelligent decision-making", accelerating the design of cell factories, path reconstruction and process optimization. At the same time, the wide application of non-food resources and one-carbon raw materials will open up new raw material supply channels for bio-manufacturing, alleviating the competition and contradiction between traditional food resources and bio-manufacturing, and enhancing the industry's resilience.

Although China has made significant progress in the field of bio-manufacturing, it still faces many challenges, such as the issue of the independent controllability of core strains, the lag in the research and development of intelligent equipment and high-end equipment, and the insufficient independent innovation ability of key technologies. To address these challenges, it is necessary to increase investment in basic research, promote breakthroughs in key technologies, and further enhance the independent controllability of the industry.

Overall, the biomanufacturing technology has shown a trend of coordinated advancement in intelligence, greenness and scale globally. Through continuous technological innovation, improvement of the industrial system and policy and institutional guarantees, China is expected to further consolidate its core competitiveness in the field of biomanufacturing, and play a more significant leading role in promoting the global green economy and sustainable development.

Source: Science and Technology Review