Polylactic acid (PLA) fibers are made from biomass resources such as corn, sugar cane, and wheat. These resources are converted into sugar and then fermented by microorganisms to obtain lactic acid monomers. These monomers are subsequently polymerized to form PLA polymers, which are then further processed into fiber products. PLA fibers are completely biobased materials with the property of biodegradability. Compared with traditional polyester fibers such as PET fibers, PLA fibers still have gaps in terms of strength, heat resistance, and hydrolytic resistance. This makes them more suitable for "use-and-throw" or applications with a shorter life cycle.

The processing flow of PLA fibers can be summarized as: biomass - sugar - lactic acid - PLA - fibers. That is, the biomass raw material is hydrolyzed to form fermentable sugars, which are then converted into lactic acid under the action of microorganisms. Subsequently, PLA sheets are produced through condensation or ring-opening polymerization, and fibers or non-woven materials are formed through melt spinning or spunbonding processes. Due to the chiral structure of lactic acid molecules, PLA can be classified into left-handed poly(lactic acid) (PLLA), right-handed poly(lactic acid) (PDLA), and racemic poly(lactic acid) (PDLLA), among others. Among them, PLLA, which has better crystallinity and thermal stability, is the most suitable for fiber and non-woven fabric processing and has become the most widely used PLA fiber raw material at present.

PLA is a thermoplastic polymer material and can be spun using conventional melt-spinning equipment. Its processing is highly sensitive to moisture and temperature conditions. To prevent the material from depolymerizing at high temperatures, it is usually necessary to dry the raw materials before spinning and complete the melt extrusion and fiber formation within an appropriate temperature range. In the actual production process, after the primary fibers undergo a certain multiple of thermal stretching orientation, they are then subjected to post-treatment procedures to obtain short fiber products with certain mechanical properties and processing adaptability. Depending on the different web-forming methods of non-woven fabrics, the length of PLA short fibers is adjusted accordingly. For example, in dry web-forming, longer fibers (30-70 mm) are usually selected, while in wet web-forming non-woven fabrics, shorter fibers (2-6 mm) are used to meet the requirements of web formation uniformity and process stability.

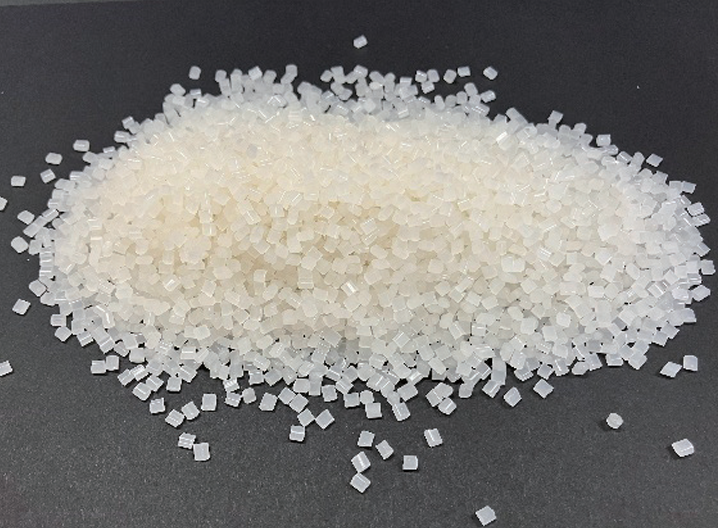

The NatureWorks company in the United States, as the world's largest manufacturer of biopolymers, has developed a multi-series and multi-brand layout for its Ingeo™ PLA resin, which can meet the requirements of fibers, non-woven fabrics, and engineering applications. In Japan, Teijin has developed PLA resin BIOFRONT™ (Figure 1) by introducing biodegradable promoters into the polymer system, which has more efficient degradation performance and can be used in fiber materials like conventional PLA polymers. In Japan, Unitika has launched the Terramac™ series, which has made progress in the direction of PLA elastic fibers.

Figure 1 BIOFRONT™ Resin Particles

In terms of the industrialization construction of PLA fibers in China, Ma'anshan Tongjie Liang Bio-materials Co., Ltd. has built a PLA production line with an annual output of 10,000 tons and a spinning line with an annual output of 1,000 tons. They have developed PLA chips for injection molding, sheeting, film, and fibers, and have produced PLA short fibers and hygiene materials products. Yisheng New Materials (Suzhou) Co., Ltd. has its own characteristics and advantages in PLA fiber research and development. Currently, it has a 10,000 t/a melt direct spinning PLA fiber production line; three functional PLA fiber production lines with a capacity of 5,000 t/a, capable of producing differentiated products such as PLA three-dimensional crimp fibers, two-component composite fibers, irregular cross-section fibers, PLA long fibers, and liquid dyeing PLA fibers; in addition, it also has a 1,000 t/a PLA hot air hot-rolled non-woven fabric production line. In 2024, Anhui Huamei Textile Co., Ltd. (hereinafter referred to as "Huamei Co., Ltd.") actively promotes the construction of PLA fiber projects, with a total investment of approximately 600 million yuan, planning to build a 100,000 t/a PLA fiber project. Currently, Huamei Co., Ltd. has the ability to batch-produce 1.0 - 1.5 D PLA fibers. From the test results, the product indicators of the trial production are better than those of similar products on the market, creating conditions for further expansion of production.