PLA poly(lactic acid) powder (poly(lactic acid) powder) is a biodegradable material made from renewable plant starch. It possesses environmental friendliness, safety, and certain mechanical properties, and has become a core material for addressing issues such as "white pollution" and "non-compliance with environmental standards". From food packaging to 3D printing, from disposable products to medical materials, PLA (polylactic acid) powder precisely meets the production demands for environmental protection, safety and sustainability. This article summarizes the 20 most crucial application scenarios of PLA powder, allowing you to understand how it helps enterprises achieve green production.

I. Environmental Concerns: Say Goodbye to White Pollution and Achieve Sustainability

Plastic products are non-biodegradable and cause environmental pollution: shopping bags, courier packaging, disposable tableware, etc. Products made from PLA (polylactic acid) can completely degrade into carbon dioxide and water in the natural environment, leaving no residual pollution, thus alleviating the pressure of white pollution.

2. 3D printing materials have poor environmental performance and do not meet sustainable requirements: Industrial 3D printing, desktop 3D printing, etc. PLA (polylactic acid) powder, as an environmentally friendly consumable, is biodegradable and has low odor, replacing traditional non-biodegradable printing materials and conforming to the concept of green production.

3. The residual plastic film contaminates the soil and is difficult to recycle: For agricultural planting, plastic films made of PLA (polylactic acid) are used. These biodegradable films do not need to be recycled after use; they can naturally degrade in the soil without polluting it and will not affect subsequent planting.

4. The degradation property of the color masterbatch carrier is poor and it pollutes the environment: In the coloring process of environmentally friendly plastic products, PLA (polylactic acid) powder is used as the carrier of the color masterbatch. It is biodegradable and environmentally friendly, avoiding the environmental pollution caused by the difficulty in recycling of traditional carriers.

5. Non-woven fabrics have a slow degradation rate and cause environmental pollution: One-time hygiene products, medical non-woven fabrics, etc. Non-woven fabrics made from PLA (polylactic acid) powder can degrade rapidly, reducing the pollution of medical and household waste to the environment.

6. Electronic packaging is prone to cause white pollution and is difficult to recycle: For example, packaging materials and cushioning materials for electronic products. PLA (polylactic acid) powder can replace traditional plastic packaging. It is biodegradable, lightweight, reduces white pollution, and lowers the cost of recycling.

7. The environmental performance of building decoration materials is poor and the formaldehyde content exceeds the standard: Interior decoration materials, furniture panels, etc. PLA (polylactic acid) powder, as an environmental-friendly additive, has no formaldehyde and no odor, improving indoor air quality and meeting the standards of green buildings.

II. Safety Challenges: Ensuring Health, Meeting Special Needs

8. Poor food packaging quality and unpleasant odor: For food packaging, tableware, etc., PLA (polylactic acid) powder complies with food contact safety standards such as FDA and GB 4806. It has no odor and no release of harmful substances, ensuring food safety.

9. Disposable tableware has poor heat resistance and cannot hold hot food: After modification, the heat resistance of PLA (polylactic acid) powder has been increased to above 100℃, allowing it to hold hot food. At the same time, it is biodegradable and can replace traditional disposable plastic tableware.

10. Poor safety and presence of harmful substances in toy products: Children's toys, educational toys, etc. The PLA (polylactic acid) powder contains no heavy metals or plasticizers, is environmentally friendly and safe, avoiding the harm caused by harmful substances to children's health.

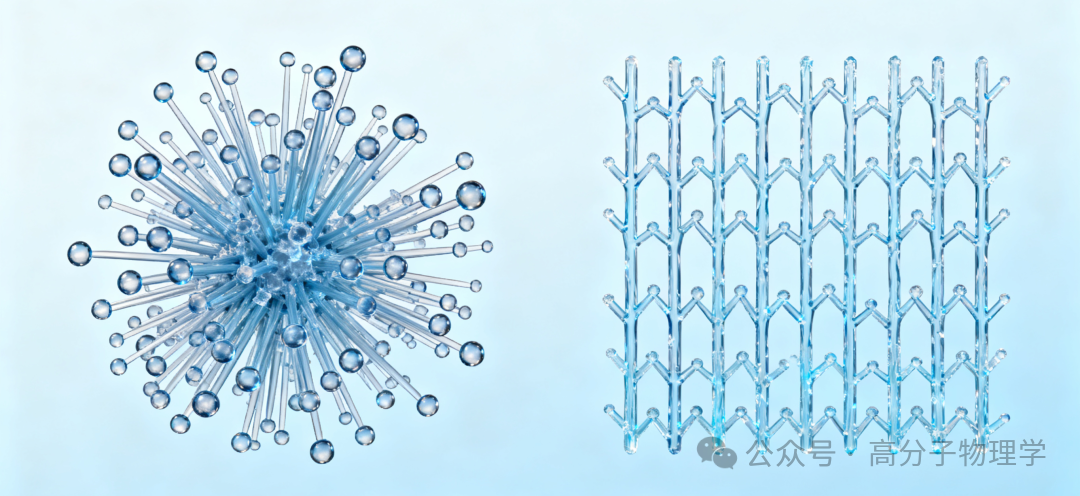

11. Poor biocompatibility and non-degradable absorption of medical materials: Medical sutures, tissue engineering scaffolds, etc. PLA (polylactic acid) powder has excellent biocompatibility and can be degraded and absorbed in the human body. There is no need for a second surgery to remove them, thereby alleviating the patient's suffering.

12. The hot melt adhesive has poor environmental performance and does not meet export standards: In the bonding and packaging processes of exported products, the hot melt adhesive made from PLA (polylactic acid) powder is environmentally friendly and biodegradable. It complies with environmental standards of countries such as the EU and the US, avoiding trade barriers.

13. Poor environmental friendliness and high VOC content: For building coatings and furniture coatings, etc., PLA (polylactic acid) powder, as an environmentally friendly film-forming material, has a VOC content far lower than the national standard. It has no irritating odor and improves the construction environment and indoor air quality.

14. The adhesive has poor environmental performance and does not meet green production standards: In scenarios such as industrial bonding and product assembly, the modified adhesive made from PLA (polylactic acid) is environmentally friendly and biodegradable, without the release of harmful substances, and complies with the green production requirements of enterprises.

III. Performance Challenges: Balancing Environmental Friendliness and Practicality

15. Insufficient toughness and prone to cracking: For environmentally friendly packaging films and degradable bags, after modification, the PLA (polylactic acid) powder significantly improves its toughness, enhancing its resistance to tearing and puncturing, thus preventing packaging damage caused by brittleness.

16. Modified plastics have a narrow processing temperature range and are prone to decomposition: In the processing of environmentally friendly plastic products, the PLA (polylactic acid) powder is optimized for processing techniques to expand the processing temperature range, prevent decomposition during the processing, and ensure product performance.

17. The textile fibers have poor skin-compatibility and are uncomfortable to wear: For clothing and home textile products, the fibers made from PLA (polylactic acid) powder have good skin-compatibility, breathability, and moisture absorption, making them comfortable to wear. At the same time, they are biodegradable and environmentally friendly, sustainable.

18. Large shrinkage rate of injection molded parts and low dimensional accuracy: For environmentally friendly plastic parts and daily necessities, reducing the shrinkage rate of injection molded parts with PLA (polylactic acid) powder can improve dimensional accuracy, reduce subsequent processing, and ensure product quality.

19. Modified plastics have poor impact resistance and high brittleness: For environmental-friendly household appliances, outdoor products, etc., PLA (polylactic acid) powder reinforced materials have good impact resistance, reduce brittle fractures, and balance environmental friendliness and durability.

20. Poor barrier properties, easy gas permeability: For example, in environmentally friendly food packaging films. The PLA (polylactic acid) powder reinforced film enhances the barrier properties against oxygen and water vapor, prolonging the shelf life of the food while maintaining its degradable characteristic.

Conclusion: PLA Polylactic Acid Powder - The "Environmental Pioneer" of Green Production

In the current era where environmental protection policies are becoming increasingly strict and the concept of sustainable development is deeply rooted in people's minds, PLA (polylactic acid) powder, with its core advantages of being environmentally friendly and biodegradable, safe and non-toxic, has solved the pollution problems of traditional plastic products. At the same time, it also takes into account practicality and processability, making it the preferred material for green production. Its wide application not only helps enterprises achieve environmental transformation but also promotes the entire manufacturing industry towards a sustainable direction.