Thanks to its lightweight, durability and low cost, plastic was hailed as "one of the greatest inventions of the 20th century", and it has permeated every corner of life, from supermarket shopping bags to takeout food containers. But behind the convenience lies a heavy environmental cost: globally, over 200 million tons of plastic are produced each year, and according to data from the United Nations Environment Programme in 2022, over 300 million tons of plastic are discarded annually, with 14 million tons of it flowing into the oceans. Traditional plastics are "inert for a century", and microplastics enter the human body along the food chain; polyethylene plastic film used in farmland damages the soil structure and hinders crop growth. As "white pollution" becomes increasingly severe, biodegradable plastics have become the key direction that people are expecting to "ensure the plastic has a good ending".

Biodegradable plastics: Not "easy to dissolve", but "convertible"

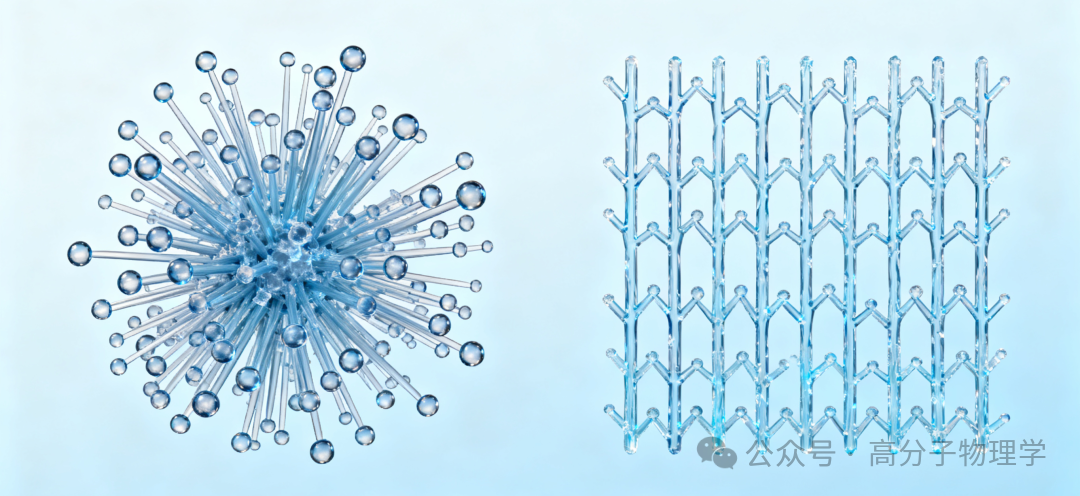

Many people mistakenly believe that biodegradable plastics are "capable of disintegrating upon contact with water" or "easily breakable". In fact, their core definition is: under suitable temperature, humidity and microbial conditions, they can be decomposed by microorganisms such as bacteria and molds, ultimately converting into water, carbon dioxide and harmless biomass. Their degradation cycle is shortened to several months to several years, but it is greatly affected by environmental factors and cannot degrade rapidly in all scenarios. Currently, the mainstream biodegradable plastics are mainly divided into four categories, each with its own characteristics and application scenarios.

1. PLA: The Everyday "Plant-Based Star"

PLA (Poly Lactic Acid) is made from renewable crops such as corn starch and sugar cane. Through fermentation, the starch is converted into lactic acid, and then it undergoes polymerization to be produced. In daily life, the disposable coffee cups of coffee chain brands like Starbucks and Costa, the transparent fruit trays in supermarkets, and even some 3D printing materials, their core materials are all PLA.

Advantages: The raw materials are all derived from renewable resources. The degradation products are non-toxic and harmless, aligning with the "green environmental protection" concept.

Limitations: Degradation requires strict industrial composting conditions at high temperatures - the temperature must be maintained at 55-60°C, with sufficient oxygen and humidity; if randomly thrown into a regular trash can or natural environment, the degradation rate is almost the same as that of traditional plastics. Additionally, PLA has poor mechanical properties and poor heat resistance; it will deform and soften above 60°C and is not resistant to oil stains, so it cannot be used to hold hot soups or fried foods.

2. PHA: The "All-Purpose Degradation Champion" with Strong Environmental Adaptability

PHA (Polyhydroxyalkanoates) is naturally produced by microorganisms such as Rhodobacter and Pseudomonas by fermenting organic substances like sugars and lipids. Its most remarkable feature is its extremely strong environmental adaptability. It can be naturally decomposed by local microorganisms in various environments, including moist farmlands, freshwater lakes, and high-salt oceans. The degradation cycle can be controlled within several months to one year.

Advantages: Widely applicable in various scenarios. Besides food packaging films (such as preservation bags), it is also used in the medical field due to its excellent biocompatibility - for absorbable sutures in surgical operations (no need to remove the stitches, they can degrade naturally in the body), and drug sustained-release carriers (allowing drugs to be released slowly, reducing the frequency of medication intake).

Limitations: The production cost is extremely high, approximately 2-3 times that of traditional polyethylene (PE) plastic. Currently, it can only be applied on a small scale in the high-end medical field, and it is difficult for ordinary consumers to access pure PHA products.

3. PBAT: The "Balancer" that Combines Practicality and Biodegradability

PBAT (Polybutylene Adipate/Terephthalate) is derived from petroleum (a petroleum-based plastic), but through special molecular structure design, it possesses excellent biodegradability. It has excellent flexibility, is impact-resistant and resistant to stretching. When used alone, it can be used as garbage bags and shopping bags. It is also often mixed in proportion with PLA - it can not only compensate for the brittleness and fragility of PLA, but also improve the overall degradation efficiency.

Advantages: The process is convenient and can directly utilize traditional plastic production equipment. Enterprises do not need to make additional investments to upgrade their production lines. The core component of the "degradable environmental bags" and agricultural degradable plastic films currently being promoted in China is PBAT.

Limitations: The raw materials rely on fossil resources and cannot achieve complete renewable from "source to end", there are still certain issues related to resource consumption.

4. PCL: "Special Materials" Focused on Healthcare

PCL (polycaprolactone) is formed by polymerizing caprolactone monomers. It has excellent biocompatibility. The degradation products (caprolactone) are non-toxic to the human body, and the degradation rate can be controlled by the molecular structure - for example, when used as a scaffold for bone tissue repair, it can precisely match the healing speed of the bone, and gradually degrade after new bone grows, avoiding the need for a second surgery to remove it.

Advantages: It has high adaptability in the medical field and is an important material for drug controlled-release systems and medical implants.

Limitations: Low mechanical strength, slow degradation rate in natural environment (usually 1-2 years), unable to meet the durability and degradation efficiency requirements of daily consumer products, the application scope is mainly limited to niche medical fields, and it is rarely encountered by ordinary consumers.

Gradually permeating life: The practical application of biodegradable plastics

In fact, biodegradable plastics have long been integrated into daily life, replacing traditional plastics in various scenarios to reduce pollution risks:

Dining scenario: The disposable coffee cups of Starbucks and Costa are mostly made of PLA material; some online food delivery platforms promote "degradable food boxes", which are mainly composed of PBAT and PLA mixed materials, avoiding the problem of traditional food boxes being "thrown away after use and causing long-term pollution".

Supermarket scenario: The transparent packaging films used for wrapping vegetables and meats in the fresh food section of supermarkets are mostly made of PHA or PBAT materials. They not only ensure the freshness of the food but also can naturally decompose after disposal. The "degradable fruit trays" are a typical application of PLA, replacing the traditional foam trays.

Daily shopping: With the implementation of the "plastic restriction order", many cities in China have fully adopted biodegradable shopping bags. These bags are mainly made of PBAT as the core material, featuring good flexibility and strong load-bearing capacity. After entering the industrial composting environment, they can complete degradation within several months.

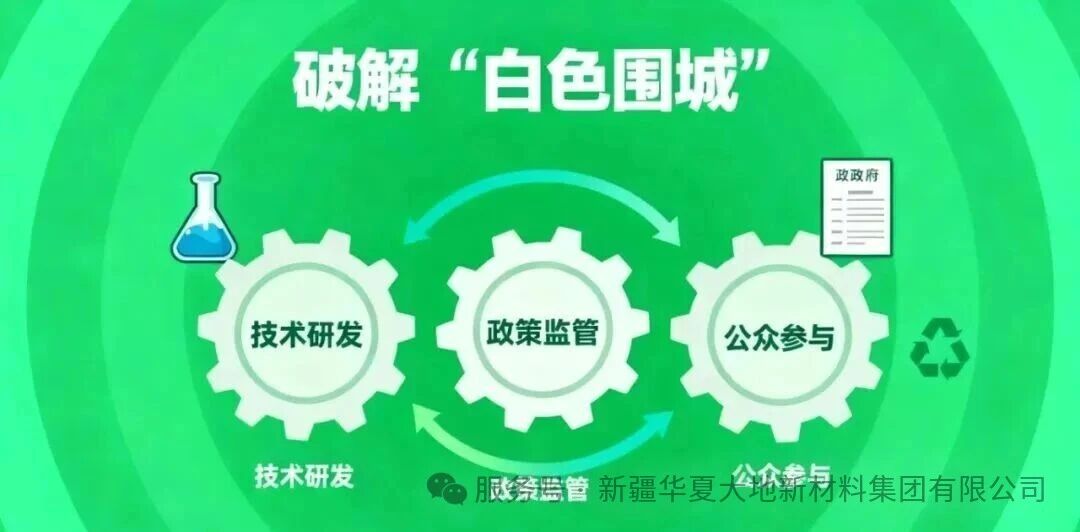

Overcoming Pollution: Requires a Synergistic Effort from Technology, Policy and Public Participation

Biodegradable plastics are not a "panacea" for "white pollution". To truly realize their value, it is necessary for technology, policies and the public to work together, and they should also be combined with "plastic reduction" and "recycling":

Technical side: Explore raw material substitution, using agricultural waste such as straw and rice husks to replace corn starch in the production of PLA, thereby reducing raw material costs and resource consumption; optimize the PHA fermentation process to increase production volume and lower production costs; through blending modification technology, enhance the heat resistance and mechanical properties of PLA, and expand application scenarios.

Policy aspect: Develop scenario-specific special standards, clearly defining the performance requirements for biodegradable plastics in different scenarios; Provide subsidies for the construction of industrial composting plants to improve the terminal processing facilities for degradable plastics; Establish a "production - testing - sales" full-chain supervision system to crack down on "pseudo-degradable" products and prevent the use of inferior materials as substitutes.

Public side: Learn to identify the "GB/T 20197-2006" label for biodegradable plastics, and distinguish between genuine products; Properly dispose of waste - Clean biodegradable plastics should be placed in the recyclable category, while those contaminated by oil or food residues should be placed in other waste, to avoid affecting the degradation effect.

The management of plastic pollution cannot rely solely on any single type of material. Only by using biodegradable plastics as an "auxiliary measure", combined with "reducing plastic usage" and "promoting recycling", can a closed loop be formed from the source to the end, allowing the Earth to gradually escape the "white enclosure" and achieve harmonious coexistence between humans and nature.

The management of plastic pollution cannot rely solely on any single type of material. Only by using biodegradable plastics as an "auxiliary measure", combined with "reducing plastic usage" and "promoting recycling", can a closed loop be formed from the source to the end, allowing the Earth to gradually escape the "white enclosure" and achieve harmonious coexistence between humans and nature.