With technological breakthroughs and policy reinforcements, the valuable biomass energy crop straw is emerging as a "pioneer of new materials", "main force of green building materials", and "precious treasure of high value", taking center stage in the circular economy and low-carbon development. Today, let's together explore the "future vision" of utilizing straw as raw materials, and see how these "treasures" in the fields can drive a trillion-dollar market!

With technological breakthroughs and policy reinforcements, the valuable biomass energy crop straw is emerging as a "pioneer of new materials", "main force of green building materials", and "precious treasure of high value", taking center stage in the circular economy and low-carbon development. Today, let's together explore the "future vision" of utilizing straw as raw materials, and see how these "treasures" in the fields can drive a trillion-dollar market!

From basic materials to high-tech empowerment

Straw manufacturing exhibition hall straw worker packaging inner lining products

Straw manufacturing exhibition hall straw worker packaging inner lining products

New Materials from Straw: Beyond "Environmental Protection", They Are Also a "Treasure" of Performance

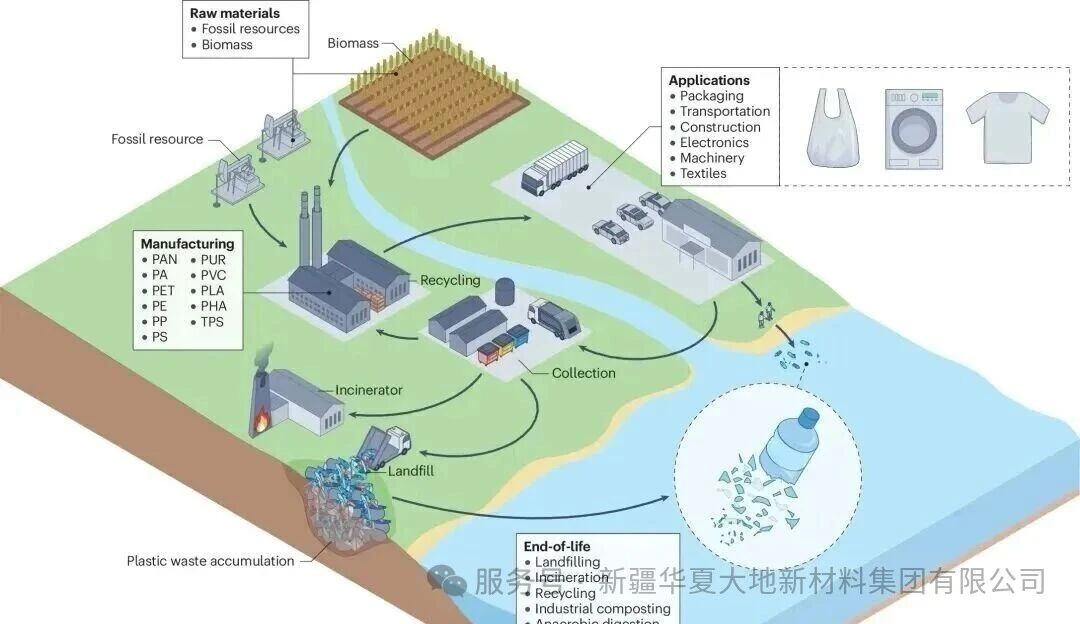

In 2026, straw will no longer merely be a "filler". Instead, through technologies such as biorefining, chemical modification, and 3D printing, it will transform into high-performance new materials. For example:

Straw-based composite materials: By combining with plastics and resins, they are used to manufacture automotive parts and home appliance shells with strength comparable to that of steel. The cost is reduced by more than 30%, and they can be fully biodegradable, making them an "environmentally friendly alternative" for new energy vehicles and smart homes. ·

Straw fiber materials: Straw fibers that have undergone nanoscale treatment are widely used in high-end textiles (such as biodegradable non-woven fabrics, antibacterial clothing) and packaging materials (as alternatives to traditional plastic courier bags). A leading e-commerce platform has announced that it will fully adopt straw-based packaging in 2026, reducing plastic usage by over 100,000 tons annually.

Straw Manufacturing Exhibition Hall Straw Building Materials Products

Straw Manufacturing Exhibition Hall Straw Building Materials Products

2. Straw Building Materials: Constructing houses and doing renovations - environmentally friendly and "extremely robust"

The problems of high energy consumption and high pollution associated with traditional building materials are being solved one by one by straw-based building materials. By 2026, technologies such as straw-based artificial boards, straw insulation materials, and straw lightweight partition walls have achieved large-scale application:

Straw particleboard/fiberboard: Made from straw as the main raw material and with the addition of formaldehyde-free adhesives, this type of board has a nearly zero formaldehyde emission rate. It outperforms traditional wooden boards in terms of water resistance and nail retention strength, becoming a "new favorite" for custom furniture and interior decoration. A major home furnishing company's annual purchase volume exceeds 5 million cubic meters.

Straw-based insulation bricks/wall materials: With a low thermal conductivity, a fire resistance rating of A grade, and a raw material cost only one-third of traditional insulation materials, they have a penetration rate of over 40% in rural self-built houses and green building projects, helping to achieve the "carbon neutrality" goal.

3. Straw Graphene: The Rise from "Field Grass" to "King of New Materials"

The most remarkable "black technology" is here! In 2026, the technology of converting straw biomass into graphene will be more widely applied. This technology, through high-temperature cracking and catalytic graphitization processes, converts the carbon elements in straw into high-purity graphene, with the cost reduced by more than 60% compared to the traditional graphite method:

The application scenarios include battery electrode materials (improving charging efficiency by 20%), flexible displays (lighter and more bend-resistant), and environmental adsorption materials (for treating heavy metal contaminated wastewater). A certain new energy enterprise has built the world's first straw graphene production line, with an estimated annual output value exceeding 5 billion yuan.

4. Straw-based polylactic acid (PLA): The "ultimate solution" for degradable new materials

The "battler" against white pollution - polylactic acid, is breaking away from its reliance on food crops such as corn and sugarcane and turning to straw as raw material. In 2026, a major breakthrough was achieved in the technology of enzymatic hydrolysis and fermentation of straw to produce PLA, solving the problems of low conversion rate of cellulose in straw and high cost:

Bacterial residue-based PLA can be used to make disposable tableware, plastic films, medical consumables, etc. In the context of the intensified "plastic ban" policy, the market demand has soared. According to data, the global production capacity of bacterial residue-based PLA will exceed 2 million tons by 2026, with China accounting for over 50% and becoming the largest producer of bacterial residue-based PLA in the world.

From a single mode to full industry collaboration

Straw Manufacturing Exhibition Hall Straw Environmentally Friendly Tableware Products

Straw Manufacturing Exhibition Hall Straw Environmentally Friendly Tableware Products

The implementation of technology cannot be separated from model innovation. In 2026, the utilization of straw as raw material will continue to form a "farmers + cooperatives + processing enterprises + terminal application" full industrial chain model, connecting all links such as "collection - storage - transportation - processing - sales":

Order-based agriculture + specialized storage and transportation: Enterprises sign long-term purchase agreements with farmers, with the purchase price for each mu of straw reaching 200-300 yuan (equivalent to an increase of 10%-15% for farmers). At the same time, a network of "field pre-treatment stations + regional processing centers" is established. Through techniques such as baling, compression, and drying, transportation costs are reduced, and the efficiency of storage, transportation, and processing is increased by 50%.

"Farmers and Workers Integration" Industrial Park: In major grain-producing areas (such as Northeast China and the Yellow-Huaihai Plain region), a number of straw utilization industrial parks have emerged. These parks integrate straw storage, primary processing (powdering, pulping), further processing (producing PLA, graphene), and final product manufacturing (building materials, packaging), with some parks achieving an annual output value of over 10 billion yuan and creating over 10,000 jobs.

"Internet + Straw": The online platform integrates information on the supply and demand of straw. Farmers can make appointments for on-site collection through the APP, and enterprises can promptly check the raw material prices and logistics information. A certain platform's transaction volume reached over 5 billion yuan in 2026, becoming a "super hub" for straw circulation.

In 2026, don't miss out on these "red envelopes"!

The development of the utilization of straw as raw materials is supported by the "strong backing" of national policies. In 2026, a series of targeted policies will be introduced in a concentrated manner, injecting "strength" into the industry:

Policy subsidies for "targeted irrigation": Provide a 30%-50% subsidy for the purchase of machinery for straw collection, storage and transportation. Offer a maximum of 30 million yuan in special loan interest subsidies for projects involving the high-value utilization of straw (such as graphene, PLA). A certain straw technology enterprise, with the support of policies, completed two rounds of financing within half a year and its valuation exceeded 1 billion yuan.

Tax incentives "in real money": Enterprises that utilize straw as raw materials can enjoy tax incentives such as immediate refund of value-added tax and "three years of exemption and half reduction" for corporate income tax. In some regions, straw products will also be included in the priority procurement list for government purchases (for example, government office building renovations must use a certain proportion of straw building materials).

"Combining 'prohibition of burning' with 'utilization': While strictly implementing the policy of prohibiting straw burning, the comprehensive utilization rate of straw will be included in the assessment indicators of local governments. The national target for the comprehensive utilization rate of straw in 2026 is 85%, among which the utilization rate for raw materialization needs to exceed 20% (in 2020, it was only 5%), thereby compelling local governments to increase their support efforts. "

In 2026, the utilization of straw as a raw material will write the legendary story of "turning straw into gold". Technological breakthroughs have endowed straw with the ability to "transform into seven dozen forms", and model innovation has made the industrial chain "come alive". Policy benefits have given the industry the wings to soar. In the future, as more technologies are implemented and more enterprises enter the market, straw will become a "super bond" connecting agriculture, industry and environmental protection. It will not only protect green mountains and clear waters but also create gold and silver mountains. Are you ready to embrace this "straw wave"?

In 2026, the utilization of straw as a raw material will write the legendary story of "turning straw into gold". Technological breakthroughs have endowed straw with the ability to "transform into seven dozen forms", and model innovation has made the industrial chain "come alive". Policy benefits have given the industry the wings to soar. In the future, as more technologies are implemented and more enterprises enter the market, straw will become a "super bond" connecting agriculture, industry and environmental protection. It will not only protect green mountains and clear waters but also create gold and silver mountains. Are you ready to embrace this "straw wave"?