"Biodegradable" products are everywhere, and the main character is PLA.

Entering the supermarket and opening the food delivery app, the word "biodegradable" can be seen everywhere - the green labels on shopping bags, the environmental commitments on food containers, and the safety endorsements for baby products, all are announcing the arrival of the era of degradable plastics. But beneath the noise, many people's understanding of degradable plastics still remains at the superficial level of "able to decompose". Fewer still know that the real force behind the environmental protection cause is a type of biodegradable material called polylactic acid (PLA). It is not a "minor modification" of traditional plastics; rather, it represents a complete revolution from raw material to final destination.

What is degradable plastic? It's not as simple as "marked it and it's good". The core of degradable plastic lies in breaking the "eternal properties" of traditional plastic. The molecules of traditional petroleum-based plastics have stable and strong chains, and once discarded, they will remain in the environment for hundreds of years. After decomposing into microplastics, they can penetrate everywhere. The essence of degradable plastic is to achieve "life cycle management" through precise design of the molecular structure - during the usage stage, it can have the same strength and durability as traditional plastic; once its mission is completed, it can start the decomposition process under specific conditions and eventually return to nature without leaving any stubborn residues.

Degradable plastics can be classified into three categories, and biodegradation is the main type.

Among the family of degradable plastics, not all members can achieve a true environmental recycling loop. According to different degradation mechanisms, they are divided into three groups: photodegradable plastics rely on sunlight and oxygen to "work", but they are "dependent on the weather", and are difficult to decompose in the absence of light; water-degradable plastics "disintegrate when in contact with water", and are mostly used in medical scenarios such as surgical sutures, with a relatively narrow application range; biodegradable plastics are the true "environmental main force", relying on microorganisms in soil, seawater or composting environments to "digest and decompose", ultimately converting into carbon dioxide, water and organic matter, and perfectly integrating into the natural cycle. And polylactic acid (PLA) is undoubtedly the "top star" in this group.

The core strength of PLA: From origin to performance, it is all top-notch.

The remarkable aspect of polylactic acid is already predetermined by its "origin". Unlike traditional plastics that "grow" by consuming petroleum, PLA's raw material is renewable crops such as corn, sugar cane, and cassava. The starch in these crops is fermented to extract lactic acid, which is then polymerized to form polylactic acid particles. This process completely eliminates reliance on fossil energy and builds a perfect carbon cycle loop - during the growth of these crops, they absorb carbon dioxide from the air. During the production and use of PLA, no additional carbon emissions are generated. When it degrades, the released carbon dioxide can be absorbed by new crops, achieving "carbon neutrality".

For a long time, the stereotype that "environmentally friendly materials are not durable" has deeply rooted in people's minds. However, PLA has completely shattered this prejudice. Its hardness, toughness and transparency have all reached the standards for food-grade applications. It can be made into lunch boxes that can withstand hot soup, shopping bags that are not prone to damage, as well as high-transparency food packaging films and soft non-woven fabrics. The tableware made from PLA has high heat resistance, which can meet the daily dining needs. Hot rice and soup will not deform or leak. The barrier property of PLA packaging films is far superior to that of ordinary cling films, and it can effectively extend the shelf life of fresh food and pastries. From food delivery to clothing textiles, from food packaging to 3D printing, the application scenarios of PLA are constantly expanding, truly achieving the two-way pursuit of "environmental protection" and "practicality".

The ultimate charm of PLA lies in its complete closed loop of "originating from nature and returning to nature". Under industrial composting conditions (with a temperature of 55-60℃, appropriate humidity, and sufficient microorganisms), PLA products can be completely decomposed within 3 to 6 months, leaving only carbon dioxide and water as the final products. These are not only harmless to the environment but also become nutrients for the soil. Even in natural environments, such as soil or seawater, PLA can gradually degrade under the slow action of microorganisms, unlike traditional plastics which break down into microplastics and cause continuous harm to the ecosystem.

Safety Tips and Future Outlook

Of course, we also need to be vigilant against the "pseudo-degradation" traps in the market. Nowadays, many plastic products claim to be "degradable", but in fact, they merely add starch and other easily decomposable components to ordinary plastic. This "fraudulent" material, after being used, the starch part will be decomposed by microorganisms, but the plastic matrix will still remain, forming invisible microplastic particles, which actually aggravates the pollution. However, true degradable plastics must meet the two core standards of "complete degradation" and "harmless residue" - this is also the key reason why PLA stands out: its decomposition process is a complete molecular-level disintegration, rather than simple physical fragmentation.

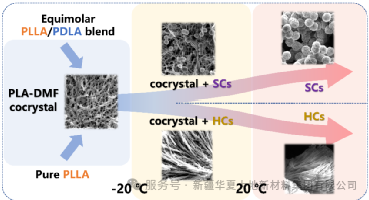

It is undeniable that PLA is not perfect. Its rapid degradation relies on professional composting facilities. If it is randomly discarded in ordinary landfills, the degradation speed will significantly slow down; its heat resistance still has room for improvement and it cannot be used in high-temperature boiling scenarios; the production cost is also slightly higher than that of traditional plastics. However, these problems are gradually being solved with the advancement of technology - through blending and modification with other materials, the heat resistance and toughness of PLA are constantly improving; large-scale production has also made its price gradually more affordable.

From a broader perspective, the rise of PLA is not only a victory for a material, but also the implementation of a sustainable development concept. The production and disposal of traditional plastics is a one-way game of "resource consumption - pollution emission"; while PLA has established a "resource regeneration - recycling" closed-loop model. When we choose a PLA lunch box or a PLA shopping bag, what we are choosing is not just a product, but also a lifestyle of reconciliation with nature. In the future, with technological breakthroughs and the improvement of supporting facilities, PLA will surely replace traditional plastics in more fields and become the core weapon for humanity to deal with the plastic pollution crisis.